Production line data exchange system

A production line data and exchange system technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of expensive industrial control terminals, huge client version, increased workload and difficulty of hardware maintenance, etc. Achieve the effects of powerful real-time information processing capabilities, complete networking integration capabilities, and flexible application configuration modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

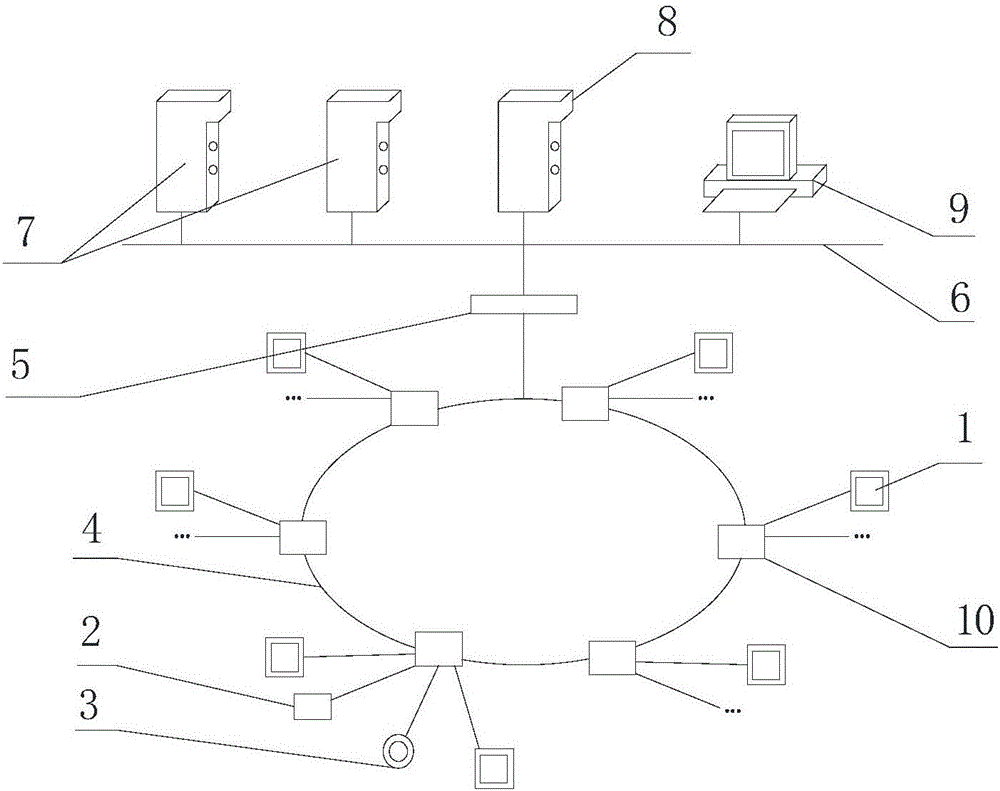

[0029] Such as figure 1 As shown, a production line data exchange system includes: data acquisition station 1, PLC controller 2, monitoring system 3, data acquisition network 4, switch 5, Ethernet LAN 6, database server 7, IFIX centralized control server 8 and centralized control Terminal 9, the data acquisition station 1, PLC controller 2, and monitoring system 3 are connected to the data acquisition network 4 through industrial optical fibers, and the data acquisition network 4 is connected to the Ethernet LAN 6 through a switch 5. The database server 7, IFIX The centralized control server 8 and the centralized control terminal 9 are directly connected to the Ethernet local area network 6 .

[0030] Wherein, the data acquisition network 4 is composed of several optical fiber switches 10, and the optical fiber switches 10 are connected in series through optical fibers to ensure the stability and reliability of the system.

[0031] Described number collecting station 1 select...

Embodiment 2

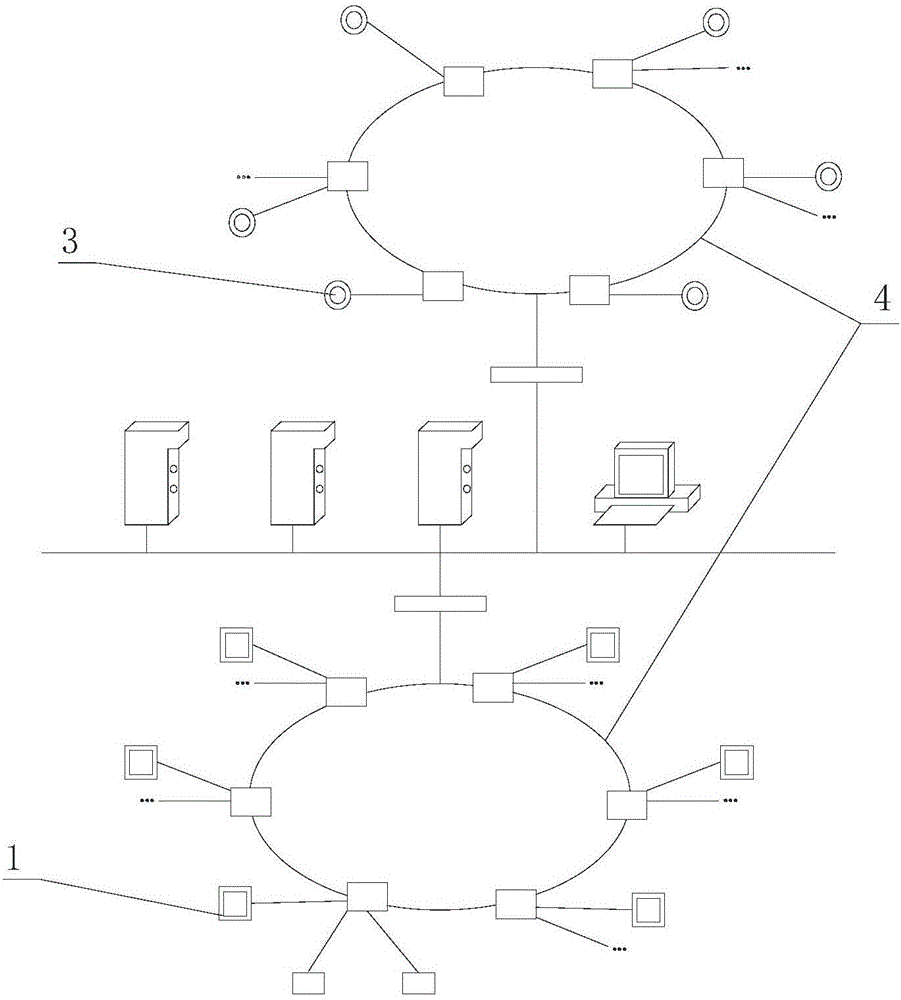

[0055] Such as figure 2 As shown, the structure of a production line data exchange system provided by the present invention is basically the same as that of Embodiment 1. The difference is that there are two data acquisition networks 4, one data acquisition network is connected to the data acquisition station 1, and the other data acquisition network is connected to the data acquisition station 1. Only the monitoring system 3 used to collect logistics data is connected to the collection network.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com