Mining deep hole laser measuring instrument

A technology of laser measuring instrument and measuring instrument, which is applied to measuring devices, measuring inclinations, radio wave measuring systems, etc., can solve the problems of low measuring efficiency, restricting digital blasting, and inability to meet blasting construction, etc., and achieves high measuring accuracy, Improve efficiency, high calculation accuracy and the effect of data acquisition semaphore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

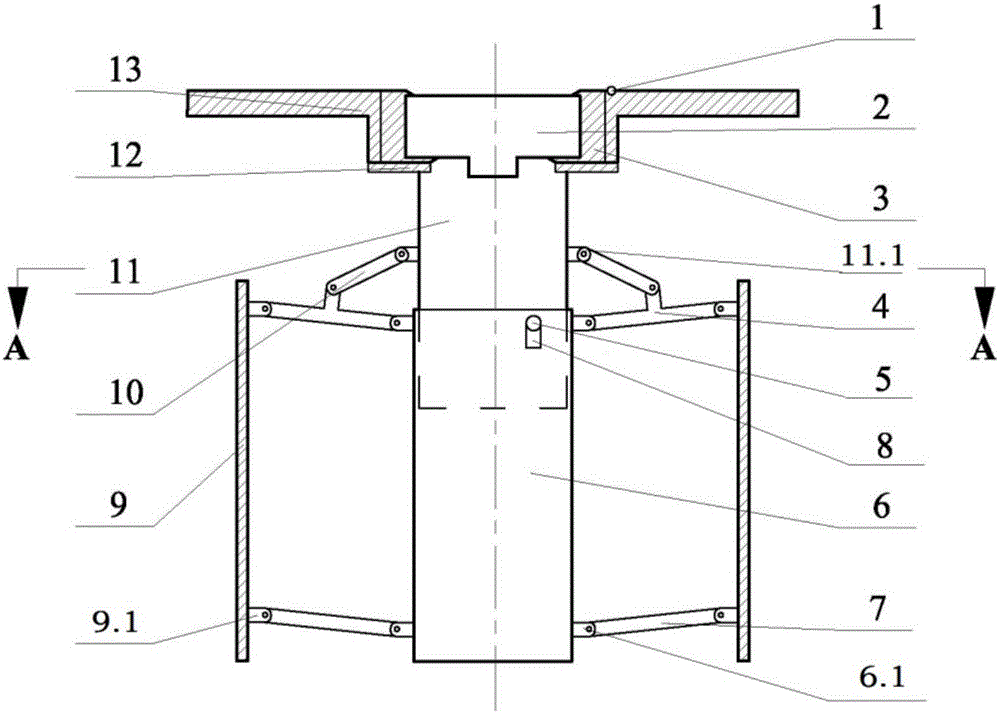

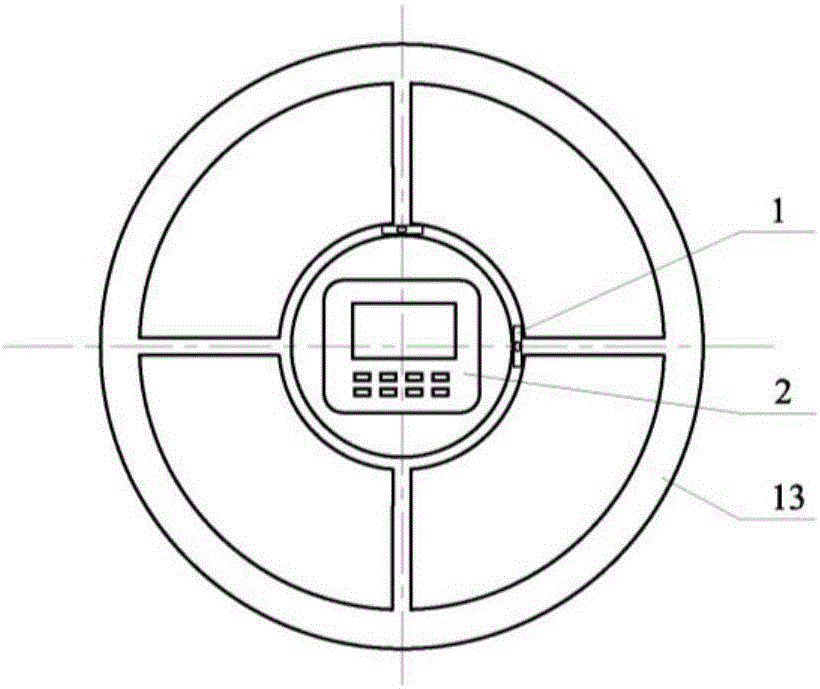

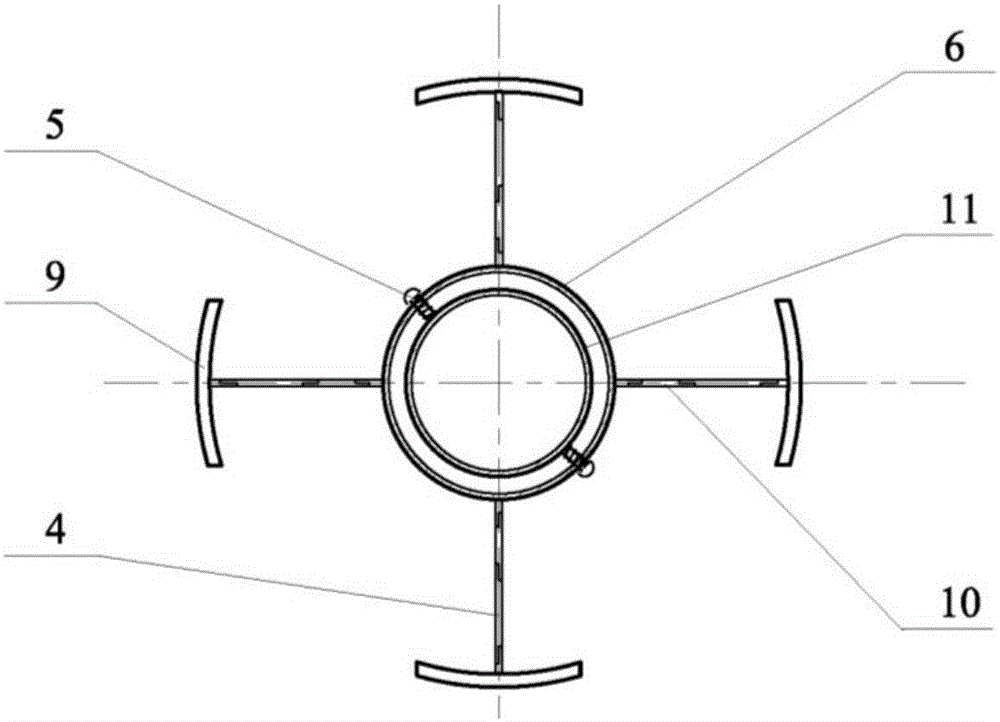

[0026] The deep hole laser measuring instrument for mine as shown in the figure, including measuring instrument 2, tray 13, level 1 and umbrella-shaped mounting bracket, measuring instrument 2 is fixed in tray 13 by rubber sleeve 3, measuring instrument 2 is used to measure blasting Hole parameters, two level gauges 1 are installed on the surface of the tray 13, and the center lines of the two level gauges 1 are perpendicular to each other; the umbrella-shaped mounting bracket includes an inner sleeve 11 and an outer sleeve 6, one end of the inner sleeve 11 and the bottom of the tray 13 It is connected by a flange 12, and the other end extends into the outer sleeve 6 and is sleeved with the outer sleeve 6. A sleeve adjusting component for adjusting the relative position of the inner sleeve and the outer sleeve 6 is also provided between the inner slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com