Lightweight brake wheel disk for high speed train

A high-speed train, lightweight technology, applied in the direction of brake discs, brake types, brake components, etc., to reduce maintenance costs, improve thermo-mechanical performance, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

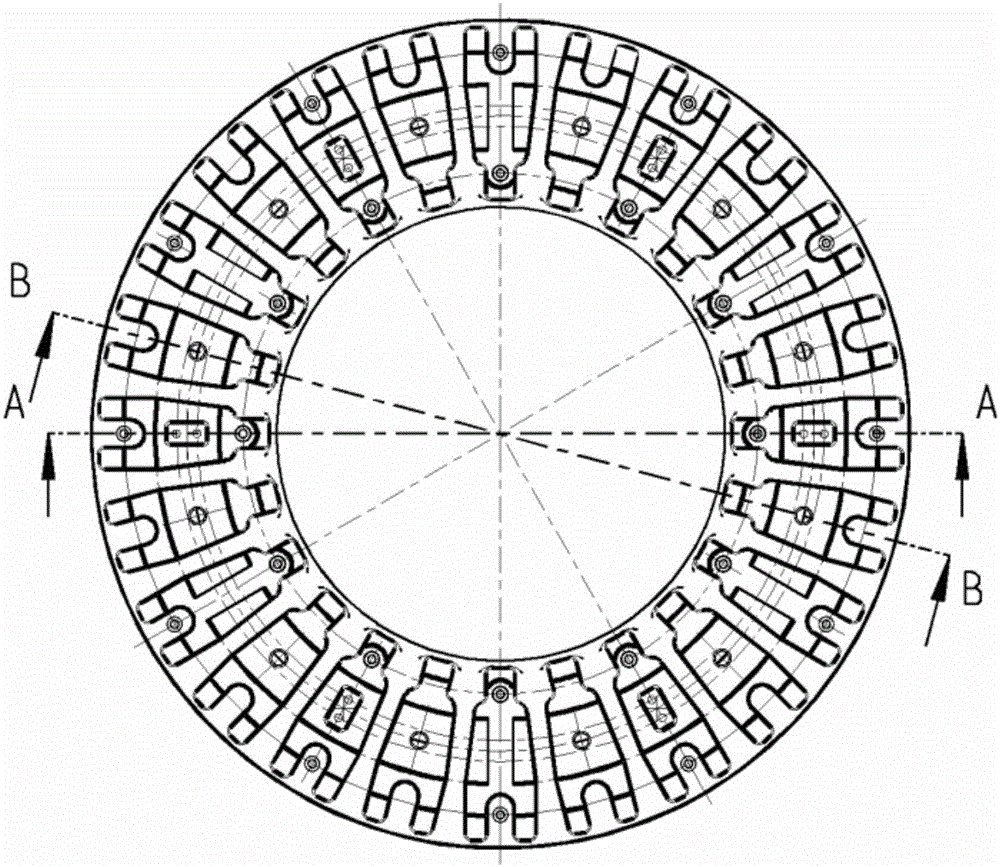

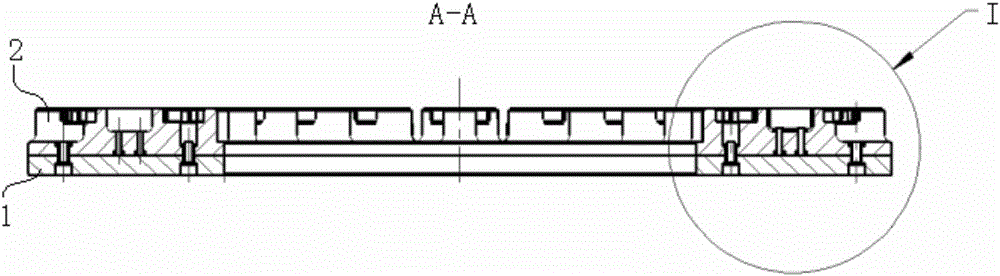

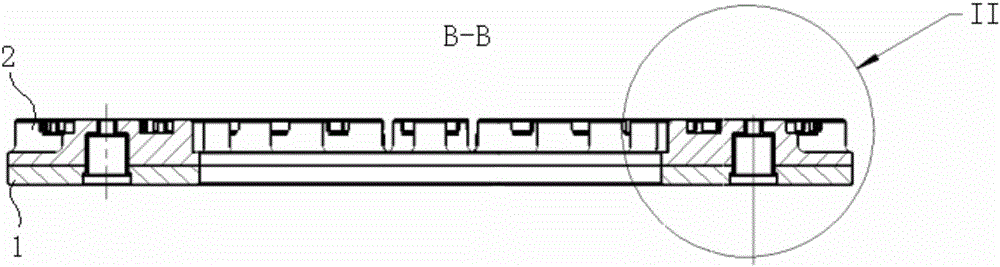

[0039] see Figure 1 to Figure 5 , the brake disc in this embodiment is a preferred embodiment of the present invention, and specifically includes a friction disc 1 and a skeleton disc 2, wherein both the friction disc 1 and the skeleton disc 2 have a disc structure with an inner ring, and the inner rings of the two The size of the ring and the outer ring are the same, and the friction disc 1 is cold riveted with the skeleton disc 2 through the first rivet 41 made of copper or steel, and is fixedly connected with the wheel through the skeleton disc 2 .

[0040] see in conjunction Figure 6-8 The friction disc 1 is made of carbon-ceramic friction material with a thickness of 10mm-20mm. Both sides of the friction disc 1 are processed into flat surfaces. On the friction disc 1, there are first rivet holes 101 arranged in an annular array around the center of the friction disc. , the first rivet holes 101 are respectively distributed in two groups near the inner ring and outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com