Road survey coring bit facilitating core separation

A technology that facilitates coring and coring drill bits, which is applied in the field of exploration and measurement, can solve problems such as inconvenient removal, easy jamming of the core column in the coring tube, troublesome coring work, etc., to achieve easy detachment, improve coring efficiency, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

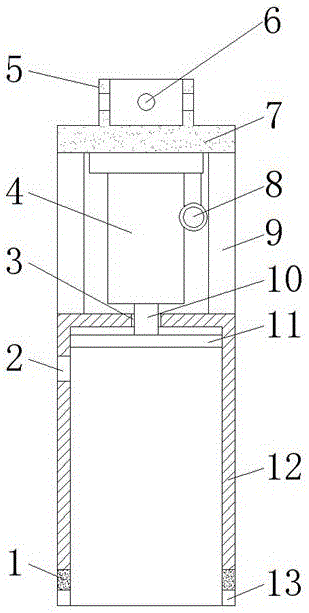

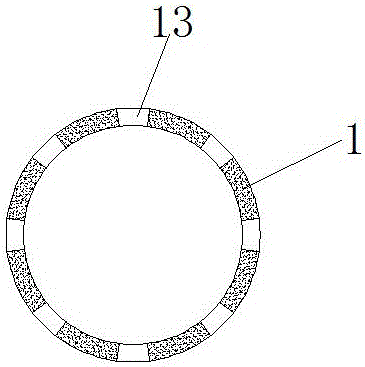

[0022] Embodiment one, refer to figure 1 , the bottom surface of the top plate 7 is welded with a jack 4, the jack 4 is provided with a lever plug 8, the piston rod 10 of the jack 4 runs through the second through hole 3 provided in the middle of the upper surface of the core tube 12 and extends to the inner cavity of the core tube 12 One end of the piston rod 10 located in the inner cavity of the coring tube 12 is welded with a top plate 11 , and the top plate 11 is slidably connected with the inner wall of the core tube 12 .

[0023] When the stem is stuck in the coring tube 12, the plunger can be inserted into the lever plug 8 to adjust the piston rod 10 of the jack 4, and the stem is pushed out by the cooperation of the piston rod 10 and the top plate 11, and the core When the head of the column is exposed to the outside of the core tube 12, the core column can be taken out by hand or clips, which is more convenient to use and improves the efficiency of coring. After the c...

Embodiment 2

[0024] Embodiment two, refer to figure 2 , the middle part of the upper surface of the coring tube 12 is provided with a threaded tube 16 communicating with its inner cavity, the threaded tube 16 is internally threaded with a threaded post 17, and the threaded post 17 is welded with a top plate 11 at one end of the inner cavity of the coring tube 12, and The top plate 11 is slidably connected with the core pipe 12 , the top end of the threaded column 17 is welded with a turning handle 14 , and one end of the turning handle 14 is covered with a sleeve 15 .

[0025] When the stem is stuck in the coring tube 12, the handle 14 can be turned to drive the top plate 11 to move down, so that the stem is ejected, which facilitates the separation of the stem and the coring tube 12. When the stem and the coring tube When the 12 cards were tighter, the sleeve pipe 15 could be placed on the rotary handle 14 to increase the arm of force, to achieve the purpose of labor saving, to facilitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com