Novel indirect-type high-temperature hydrogen fluoride ionized gas cleaning reactant, technology and device

A gas cleaning and hydrogen fluoride technology, applied in the field of indirect high-temperature hydrogen fluoride ion gas cleaning, can solve the problems of inability to carry out deep brazing/welding work, failure to provide sufficient safety guarantee for reaction gas leakage, and lack of availability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083]The invention relates to the use of cleaning agent related to the new indirect high-temperature hydrogen fluoride ion gas cleaning technology, the chemical reactions related to the cleaning process, the cleaning process and the corresponding cleaning equipment and other aspects of technical content. The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

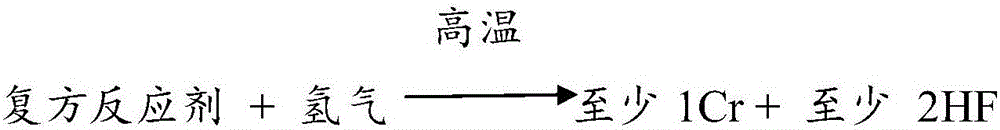

[0084] The invention provides a novel indirect high-temperature hydrogen fluoride ion gas cleaning reagent, which is made of solid CrF 2 The main compound, metal Cr and solid ammonium bifluoride form a compound reactant according to the mass ratio (3.0-20.0):(80.0-97.0):(0.3-3.0). The selection of this compound reactant not only avoids the surface area carbon problem of cleaning parts that may be caused by the use of Teflon, but also can effectively reduce the consumption of ammonium bifluoride, wherein the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com