Wet treatment comprehensive recycling technology of copper anode mud

A technology of copper anode slime and wet treatment, applied in the direction of photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems of wasting energy, wasting tellurium, tin, pollution, etc., to improve the working environment and reduce smoke The effect of generation and reduction of loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

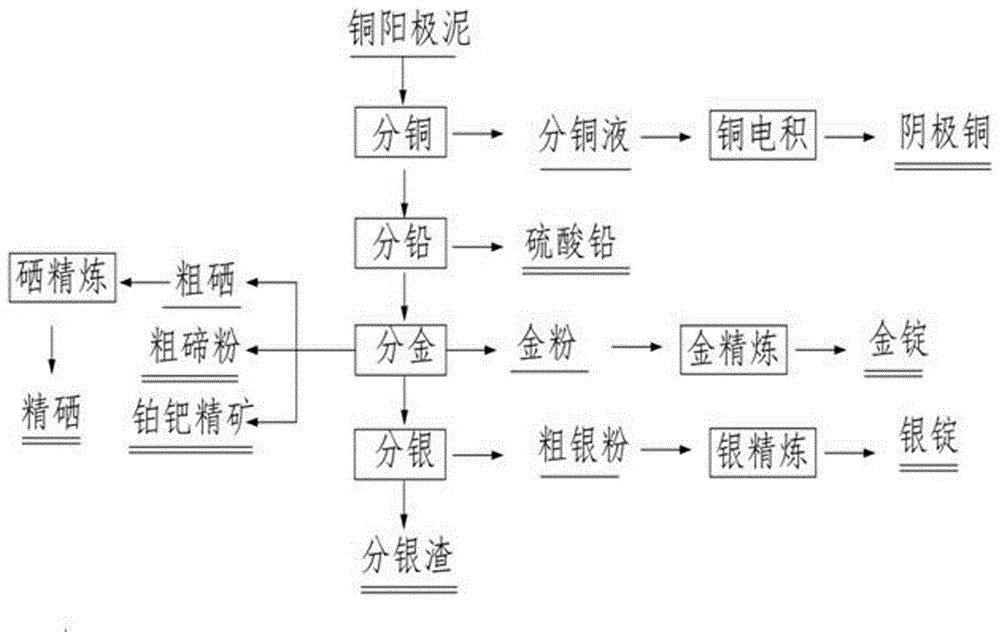

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A copper anode slime wet treatment comprehensive recovery process, the process flow is: copper anode slime - high pressure leaching - copper separation, copper separation liquid to send copper electrowinning - lead separation, lead separation liquid to sink lead to obtain lead sulfate - separation Gold, gold separation liquid reduction to obtain coarse gold powder, then send selenium tellurium platinum palladium process to extract selenium, tellurium, platinum palladium - silver separation, silver separation liquid reduction to obtain coarse silver powder - coarse gold powder casting gold anode, gold electrolysis, electrogold casting into gold ingots - Coarse silver powder is cast into silver anode, silver is electrolyzed, and electrosilver is cast into silver ingots.

[0014] The copper separation: add water and sulfuric acid to the anode slime for slurrying, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com