Polyamide-amine-alkyl ester asphalt dispersant for high pour point thick crude oil

A high-condensation heavy oil and polyamide technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., to achieve the effects of improving flow performance, significant economic benefits, anti-sedimentation ability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: asphaltene dispersant A and preparation method thereof

[0025] (1) The composition and components of asphaltene dispersant A are as follows

[0026] Main ingredient 5.0g

[0027] The solvent is benzene 5.0g

[0028] The main agent is a dendritic organic compound with multiple amide groups, ester groups and amine functional groups, and its molecular formula is as follows:

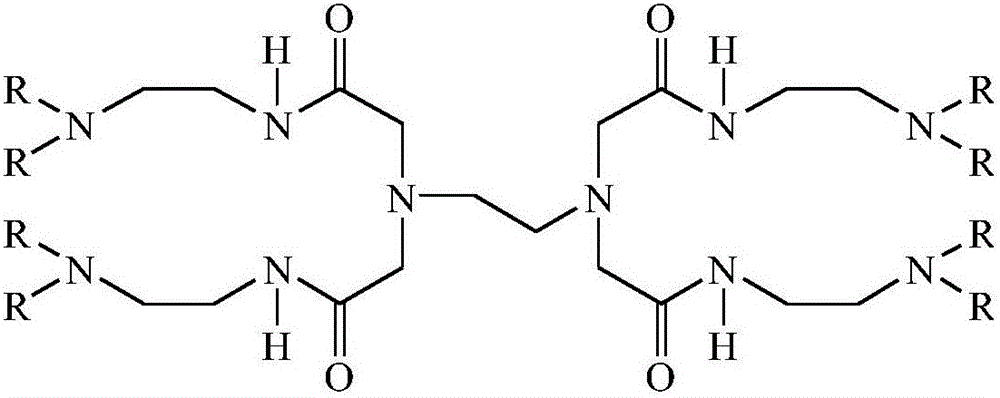

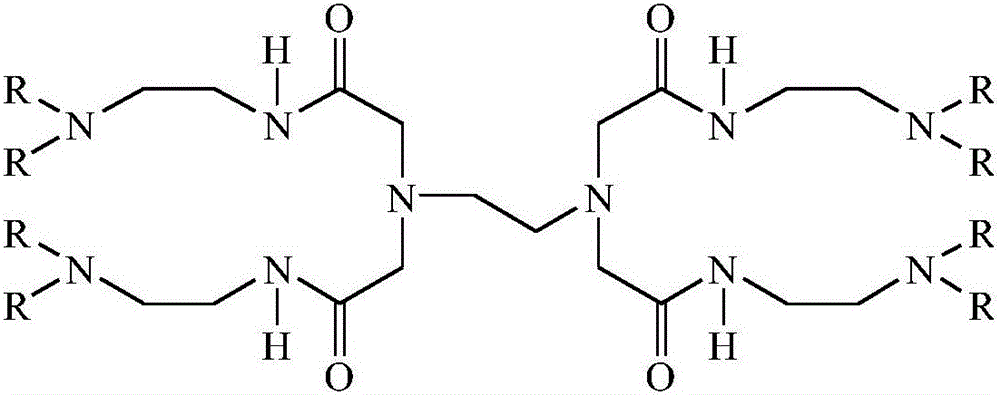

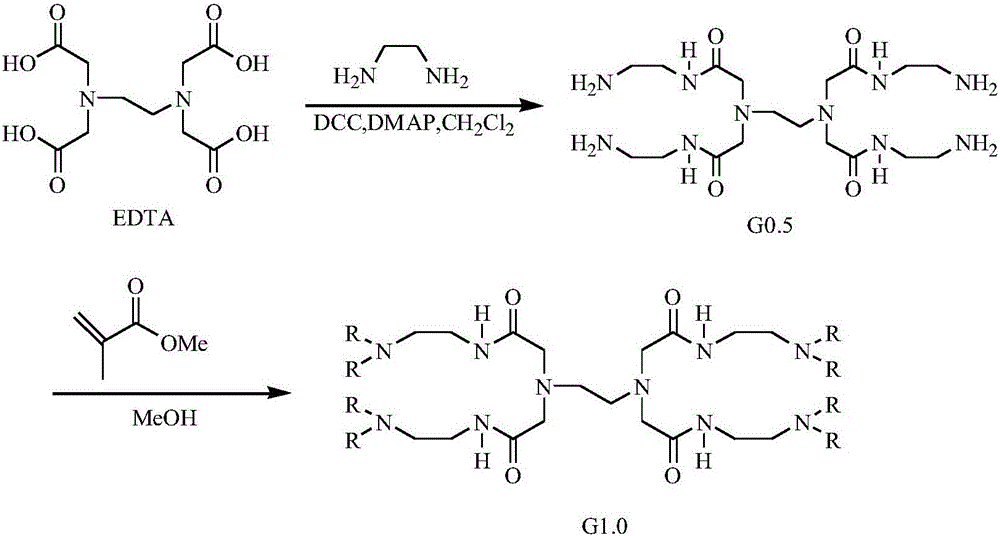

[0029]

[0030] In the formula:

[0031] (2) The preparation method of asphaltene dispersant A

[0032] ① Weigh 5.0g of solvent benzene into the beaker, and stir while heating. The heating temperature is 40°C, the heating time is 20min, the stirring speed is 200rpm, and the stirring time is 15min. After the heating time is over, the temperature is naturally cooled to room temperature;

[0033] ②Add 5.0g of the main ingredient to the above-mentioned solvent benzene, and stir while heating. The heating temperature is 55°C, the heating time is 30min, the stirring speed is 400rpm, ...

Embodiment 2

[0038] Embodiment 2: asphaltene dispersant B and preparation method thereof

[0039] (1) The composition and components of asphaltene dispersant B are as follows

[0040] Main ingredient 1.0g

[0041] The solvent is trimethylbenzene 99.0g

[0042] The main agent is a dendritic organic compound with multiple amide groups, ester groups and amine functional groups, and its molecular formula is as follows:

[0043]

[0044] In the formula:

[0045] (2) The preparation method of asphaltene dispersant B

[0046] ① Weigh 99.0g of the solvent trimethylbenzene and add it to the beaker, and stir while heating. The heating temperature is 45°C, the heating time is 25min, the stirring speed is 260rpm, and the stirring time is 10min. After the heating time is over, the temperature is naturally cooled to room temperature;

[0047] ② Add 1.0g of the main ingredient to the above trimethylbenzene solvent, and stir while heating. The heating temperature is 50°C, the heating time is 25mi...

Embodiment 3

[0050] Embodiment 3: asphaltene dispersant C and preparation method thereof

[0051] (1) The composition and components of asphaltene dispersant C are as follows

[0052] Main ingredient 2.0g

[0053] The solvent is toluene 18.0g

[0054] The main agent is a dendritic organic compound with multiple amide groups, ester groups and amine functional groups, and its molecular formula is as follows:

[0055]

[0056] In the formula:

[0057] (2) The preparation method of asphaltene dispersant C

[0058] ① Weigh 18.0g of solvent toluene into the beaker, and stir while heating. The heating temperature is 50°C, the heating time is 30min, the stirring speed is 300rpm, and the stirring time is 20min. After the heating time is over, the temperature is naturally cooled to room temperature;

[0059] ② Add 2.0g of the main ingredient to the above-mentioned solvent toluene, and stir while heating. The heating temperature is 60°C, the heating time is 20min, the stirring speed is 500rpm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com