Preparation method of multifunctional slick water fracturing fluid drag reducer

A water fracturing and multi-functional technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of long preparation time, low preparation cost, high preparation efficiency, shorten the time of liquid preparation and improve construction efficiency , The effect of simplifying the dosing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of a multifunctional slick water fracturing fluid drag reducer, comprising the steps of:

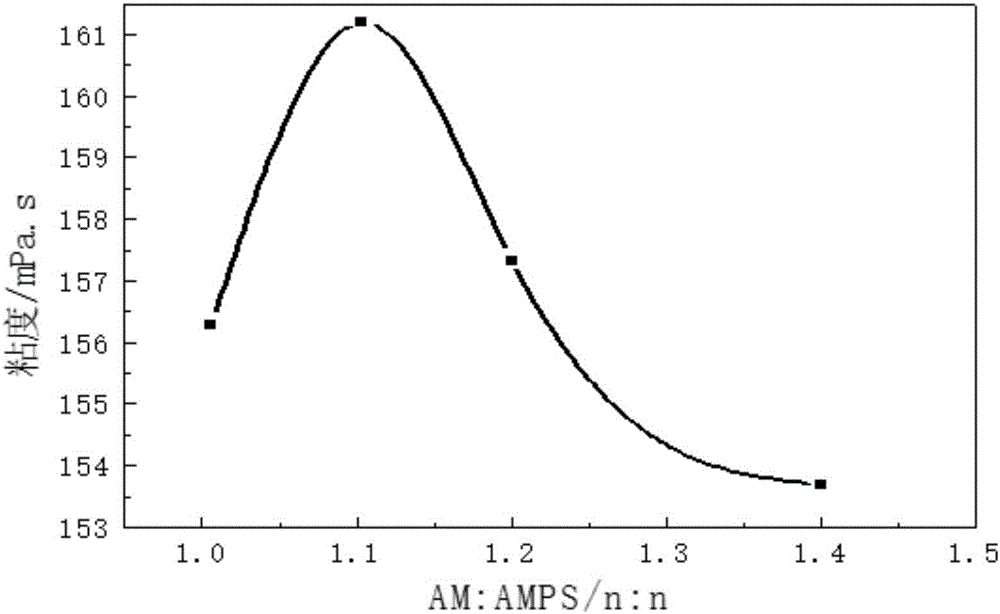

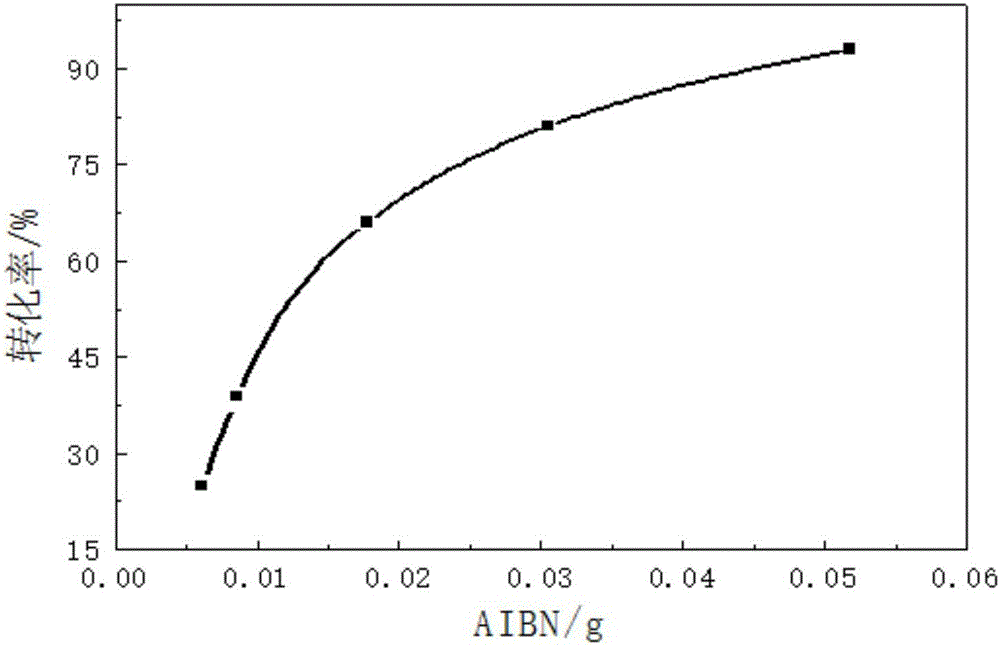

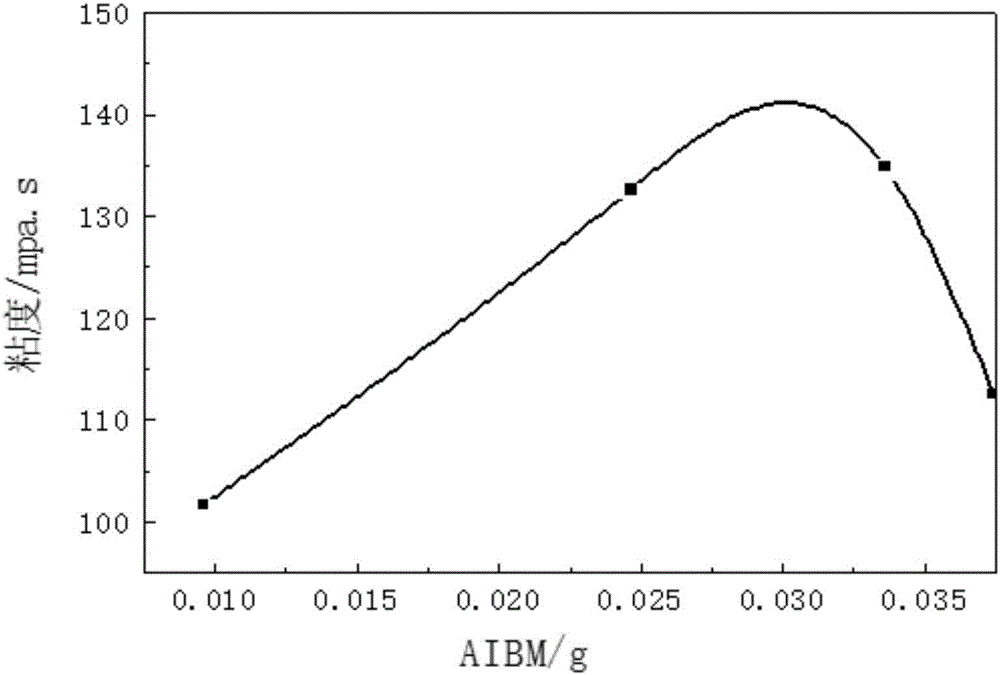

[0027] Using inverse emulsion polymerization, two nonionic emulsifiers are compounded to form a compound emulsifier, and the compound emulsifier is dissolved in an oily medium at a mass fraction of 0.3%, added to a three-necked flask, and stirred under nitrogen protection for 1 ~2h, then add 0.3% hydrophobic monomer by mass fraction, then add 0.3-0.5% chelating agent by mass fraction, and monomer solution of acrylamide and 2-acrylamide-2-methylpropanesulfonic acid, start to heat up, When the temperature rises to 52-57°C, add oil-soluble initiator and water-soluble initiator in batches, keep warm for 8-10 hours after adding the initiator, and finally obtain a stable water-in-oil polymer emulsion. 2-acrylamido-2-methylpropanesulfonic acid is introduced into the polymer molecule for the purpose of improving the salt resistance of the drag reducer.

[0028] As a ...

Embodiment 1

[0039] A preparation method of a multifunctional slick water fracturing fluid drag reducer, comprising the steps of:

[0040] Using inverse emulsion polymerization, compound two non-ionic emulsifiers to form a compound emulsifier, dissolve the compound emulsifier in an oily medium at a mass fraction of 0.3%, add it to a three-necked flask, and stir for 1 hour under nitrogen protection , then add a mass fraction of 0.3% hydrophobic monomer, then add a mass fraction of 0.3% of a chelating agent, and a monomer solution of acrylamide and 2-acrylamide-2-methylpropanesulfonic acid, start to heat up, and wait until the temperature rises to At 52°C, add an oil-soluble initiator and a water-soluble initiator in batches, and keep warm for 8 hours after adding the initiator, and finally obtain a stable water-in-oil polymer emulsion.

[0041] In the present embodiment, the two types of nonionic emulsifiers are TW60 and SP80, namely polyoxyethylene sorbitan monostearate and sorbitan monool...

Embodiment 2

[0049]A preparation method of a multifunctional slick water fracturing fluid drag reducer, comprising the steps of:

[0050] Using inverse emulsion polymerization, compound two non-ionic emulsifiers to form a compound emulsifier, dissolve the compound emulsifier in an oily medium at a mass fraction of 0.3%, add it to a three-necked flask, and stir for 2 hours under nitrogen protection , then add a mass fraction of 0.3% hydrophobic monomer, then add a mass fraction of 0.5% of a chelating agent, and a monomer solution of acrylamide and 2-acrylamide-2-methylpropanesulfonic acid, start to heat up, and wait until the temperature rises to At 57°C, add an oil-soluble initiator and a water-soluble initiator in batches, and keep warm for 10 hours after adding the initiator, and finally obtain a stable water-in-oil polymer emulsion.

[0051] In the present embodiment, the two types of nonionic emulsifiers are TW60 and SP80, namely polyoxyethylene sorbitan monostearate and sorbitan monoo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com