Compound photoinitiator with low yellowing performance and high activity

A photoinitiator and initiator technology, applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve problems that are in the experimental research and development stage, have not been widely used, and are limited to a small field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Example 1 A mixture of 30% diethylene glycol mono-benzoylformate and diethylene glycol diester benzoylformate and 70% 1-hydroxy-cyclohexyl-phenyl-methanone.

[0079] The specific composition of the photocuring system is shown in Table 1, and the exposure is performed according to the exposure conditions in Table 2.

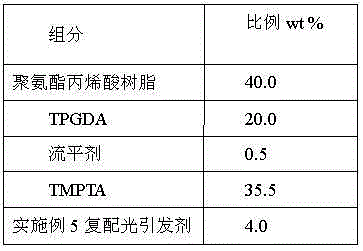

[0080] Table 1: Light curing system formulation:

[0081]

[0082] Table 2: Exposure Conditions:

[0083]

[0084] After the above formula is exposed according to the above exposure conditions, the overall curing of the coating obtained is good, the surface is smooth and uniform, the pencil hardness is >6H, the yellowing index δYI is 0.48, and the curing rate of the coating is 75% after 10 seconds of exposure, indicating that the coating has good light Initiating activity and low yellowing.

Embodiment 210

[0085] Example 2 10% mixture of diethylene glycol monoester benzoylformate and diethylene glycol diester benzoylformate, compounded with 80% BP and 10% 2,4,6-trimethylbenzoyl diphenoxyphosphine

[0086] The specific composition of the photocuring system is shown in Table 3, and the exposure is performed according to the exposure conditions in Table 4.

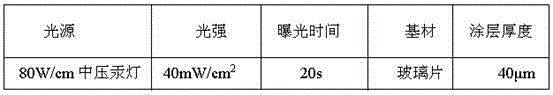

[0087] Table 3: Light curing system formulation:

[0088]

[0089] Table 4: Exposure Conditions:

[0090]

[0091] After the above formula is exposed according to the above exposure conditions, the overall curing of the coating obtained is good, the surface is smooth and uniform, the pencil hardness is >6H, the yellowing index δYI is 0.22, and the curing rate of the coating is 80% after 10 seconds of exposure, indicating that the coating has good light Initiating activity and low yellowing.

Embodiment 340

[0092] Example 3 Compound of 40% 2-hydroxy-2-methyl-1-phenyl-1-propanone, 40% benzophenone and 20% 2,4,6-trimethylbenzoyl diphenoxyphosphine

[0093] The specific composition of the photocuring system is shown in Table 5, and the exposure is performed according to the exposure conditions in Table 6.

[0094] Table 5: Light curing system formulation:

[0095]

[0096] Table 6: Exposure Conditions:

[0097]

[0098] After the above formula is exposed according to the above exposure conditions, the overall curing of the coating obtained is good, the surface is smooth and uniform, the pencil hardness is >6H, the yellowing index δYI is 0.35, and the curing rate of the coating after 10 seconds of exposure is 90%, which shows that the coating has good light Initiating activity and low yellowing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yellowness index | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com