Method for separating purified pelargonidin anthocyanin monomer from rubus hirsutus

A technique for separation and purification of pelargonidin, applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve the problems of undiscovered separation and preparation of geranidin-3-O-glucoside research and reports, and achieve the goal of overcoming Sample adsorption loss, large injection volume, good repeatability of continuous injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

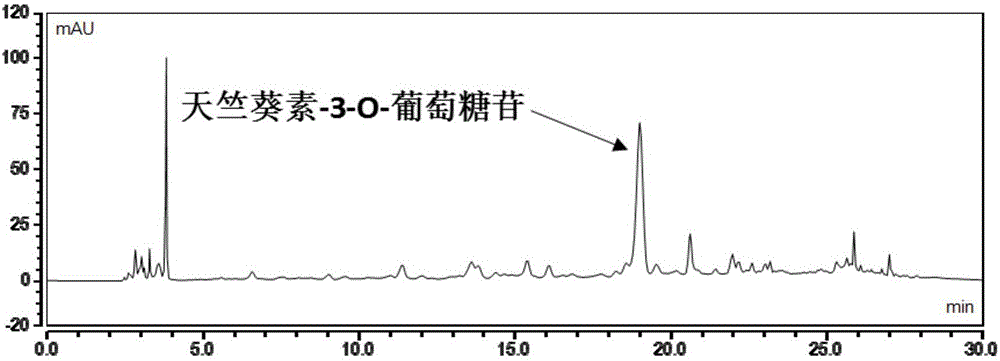

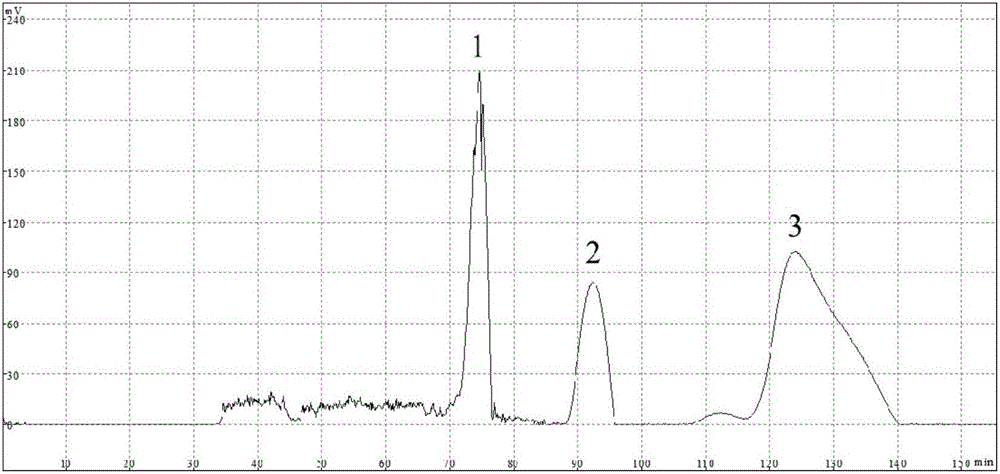

Image

Examples

Embodiment 1

[0028] (1) Wash 1000g of fresh pomegranates, add 70% ethanol solution containing 0.1% (v / v) hydrochloric acid according to the ratio of material to liquid ratio of 1g: 6mL, mix well, and ultrasonically extract for 90min (control the temperature below 45°C, Protect from light), vacuum pumping rate after the ultrasonic wave, the obtained filter residue was repeatedly extracted once according to the above conditions (changing the ratio of solid to liquid to 1g: 4mL), combined the filtrate, and removed ethanol by vacuum rotary evaporation at 40°C to obtain crude anthocyanin liquid;

[0029] (3) According to the ratio of crude anthocyanin extract: ethyl acetate volume ratio of 1:1, add ethyl acetate for extraction, let stand to separate, extract four times, collect and combine the water phase. Remove residual ethyl acetate by vacuum rotary evaporation at 40°C to obtain anthocyanin loading solution;

[0030] (4) The AB-8 macroporous resin soaked in ethanol for 24h is packed into a ...

Embodiment 2

[0038] Accurately weigh 5kg of fresh pomegranates, add 80% ethanol solution containing 0.5% (v / v) formic acid according to the ratio of material to liquid: 1g: 8mL, mix thoroughly, and extract by ultrasonic for 240min (control the temperature below 45°C, avoid light) , filtered with three layers of gauze after the ultrasonic wave, and the obtained filter residue was repeatedly extracted once according to the above conditions (changing the ratio of solid to liquid to 1g:2mL), combined the filtrate, and removed ethanol by vacuum rotary evaporation at 50°C to obtain the crude extract;

[0039] Add ethyl acetate for extraction according to the volume ratio of the crude anthocyanin:ethyl acetate volume ratio of 2:1, let stand to separate layers, extract four times, collect and combine the aqueous phases. Remove residual ethyl acetate by vacuum rotary evaporation at 50°C to obtain anthocyanin loading solution;

[0040] Put the AB-8 macroporous resin soaked in ethanol for 24 hours i...

Embodiment 3

[0043] Accurately weigh 10kg of fresh fruit, add 90% ethanol solution containing 1% (v / v) hydrochloric acid according to the ratio of solid to liquid: 1g: 10mL, mix thoroughly, and extract by ultrasonic for 240min (control the temperature below 45°C, avoid light) , the vacuum pumping rate after the ultrasonic wave is over, and the ethanol is removed by vacuum rotary evaporation at 60°C to obtain the crude extract of fenugreek anthocyanins;

[0044] According to the ratio of crude anthocyanin extract: ethyl acetate volume ratio of 1:1, ethyl acetate was added for extraction, the layers were left to stand, extracted six times, and the aqueous phases were collected and combined. Remove residual ethyl acetate by vacuum rotary evaporation at 60°C to obtain anthocyanin loading solution;

[0045] Put the AB-8 macroporous resin soaked in ethanol for 24 hours into a chromatographic column, wash it with water until there is no alcohol smell, and wash it with 4% HCL solution, deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com