Method and device for treating and recycling mine wastewater by using purified diatomite

A technology for diatomite refined soil and mine wastewater, which is applied in filtration treatment, water/sewage treatment, mining wastewater treatment, etc., can solve the problems of unsatisfactory treatment effect of pollutants, secondary pollution of chemical agents, high treatment cost, etc. To achieve the effect of unmanned management, good water output and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

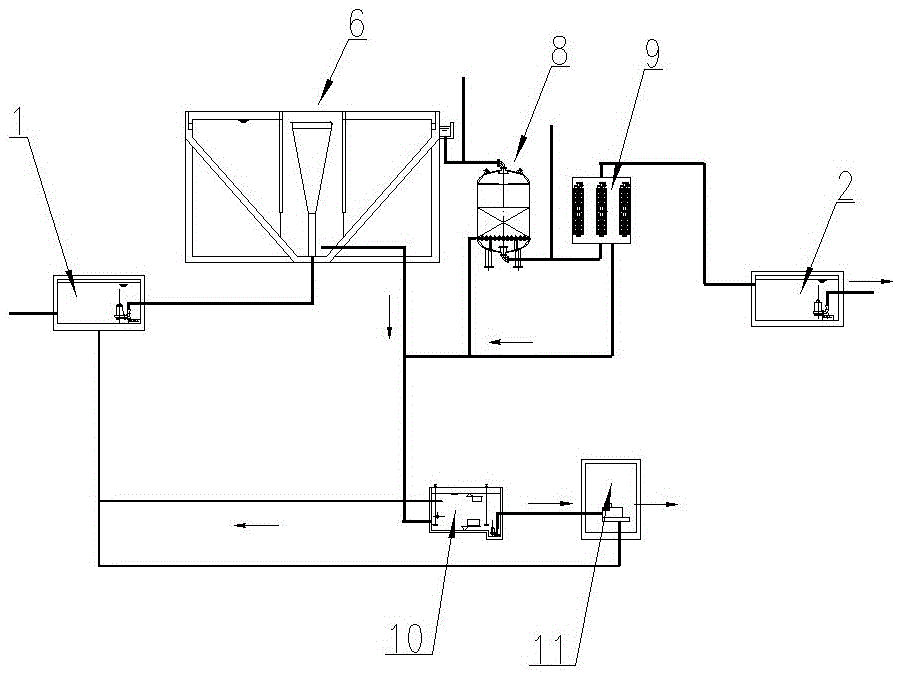

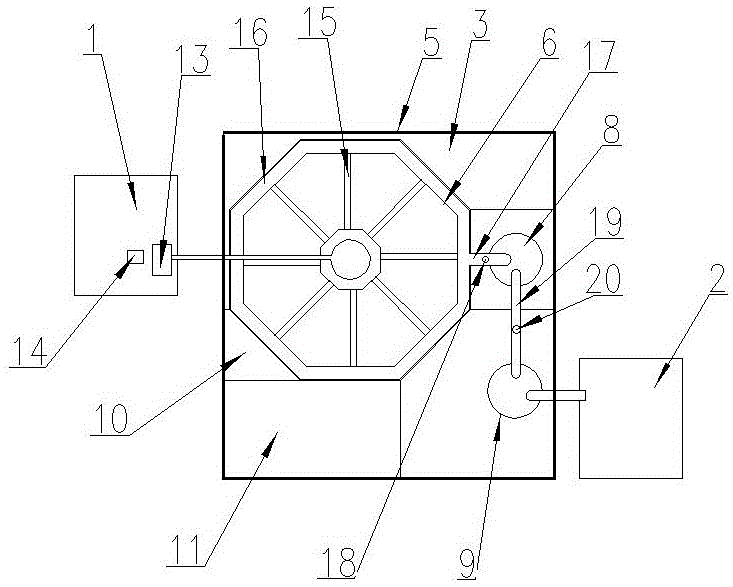

[0019] Such as figure 1 As shown, a method of using diatomite to treat mine wastewater and recycle it includes the following steps: mine wastewater is first collected through a water absorption pool 1, and the wastewater is evenly stirred by a mixer so that the fluctuating water quality can be mixed evenly At the same time, the water volume can be adjusted so that the follow-up equipment can operate continuously and stably; then the wastewater is lifted to the diatom concentrate reactor 6 through the submersible sewage pump 13, and diatom concentrate is added to the wastewater before the submersible sewage pump 13 , during the lifting process, the wastewater and diatomite are fully contacted, adsorbed and polymerized by the vigorous stirring of the pump; in the diatomite reactor 6, suspended solids, oil pollutants, part of COD and metals in the wastewater After the ions are reacted and mixed, they are adsorbed and polymerized, and then clarified in the diatomaceous earth reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com