Technology for efficient anaerobic treatment of aquaculture wastewater

A technology for anaerobic treatment and aquaculture wastewater, which is applied in anaerobic digestion treatment, animal husbandry wastewater treatment, biological water/sewage treatment, etc. problems, to achieve the effects of long residence time of sewage, improvement of treatment efficiency, and acceleration of mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

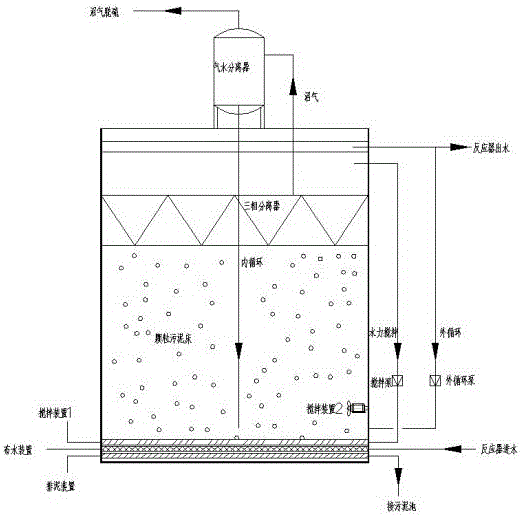

[0031] Functional introduction of each device:

[0032] Reactor---reaction vessel for the biological treatment of aquaculture wastewater. The granular sludge composed of anaerobic microorganisms in the reactor absorbs and decomposes the organic matter in the wastewater, and generates biogas while decomposing, so as to achieve the purpose of water purification;

[0033] Water distribution device -- transform one water inlet point into multiple water inlet points, so that they can be evenly distributed at the bottom of the reactor to achieve a uniform treatment effect;

[0034] The traditional anaerobic reactor design is generally in the form of point-to-point water distribution, using the gravity of water to flow into the reactor, but there is a large amount of feces in the aquaculture wastewater, and the flow rate of gravity flow is slow, which will cause feces to accumulate in the pipeline and block The water distribution pipeline affects the normal operation of the reactor. ...

Embodiment 1

[0042] Embodiment 1: high-efficiency anaerobic treatment process for aquaculture wastewater, comprising the following steps:

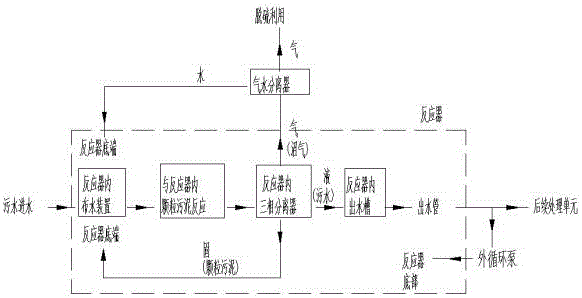

[0043] (1) The aquaculture wastewater enters the water distribution device from the bottom of the anaerobic reactor through the water inlet pipe, and the wastewater outlet points are evenly arranged in the entire reactor. The wastewater flows from bottom to top in the reactor, and passes through the granular sludge bed for bioanalysis. Oxygen treatment;

[0044] (2) The wastewater after biological anaerobic treatment enters the three-phase separator, and the pure liquid wastewater separated by the three-phase separator enters the outlet pipe through the outlet tank at the top of the reactor.

[0045] (3) The biogas separated by the three-phase separator enters the gas-water separator for gas-water separation, and the generated biogas is connected to the desulfurization device through the biogas pipeline for desulfurization and utilization;

[0046] (3...

Embodiment 2

[0051] Embodiment 2: high-efficiency anaerobic treatment process for aquaculture wastewater, comprising the following steps:

[0052] (1) The aquaculture wastewater enters the water distribution device from the bottom of the anaerobic reactor through the water inlet pipe, and the wastewater outlet points are evenly arranged in the entire reactor. The wastewater flows from bottom to top in the reactor, and passes through the granular sludge bed for bioanalysis. Oxygen treatment;

[0053] (2) The wastewater after biological anaerobic treatment enters the three-phase separator, and the pure liquid wastewater separated by the three-phase separator enters the outlet pipe through the outlet tank at the top of the reactor.

[0054] (3) The biogas separated by the three-phase separator enters the gas-water separator for gas-water separation, and the generated biogas is connected to the desulfurization device through the biogas pipeline for desulfurization and utilization;

[0055] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com