Hydraulic cavitation sterilization device with fractal pore plate

A sterilizing device and orifice plate technology, which is applied in the direction of sterilization/microdynamic water/sewage treatment, heating water/sewage treatment, light water/sewage treatment, etc., can solve the problems of poor cavitation sterilization effect of orifice plate, and achieve improvement Cavitation sterilization effect, enhanced turbulence intensity, enhanced cavitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

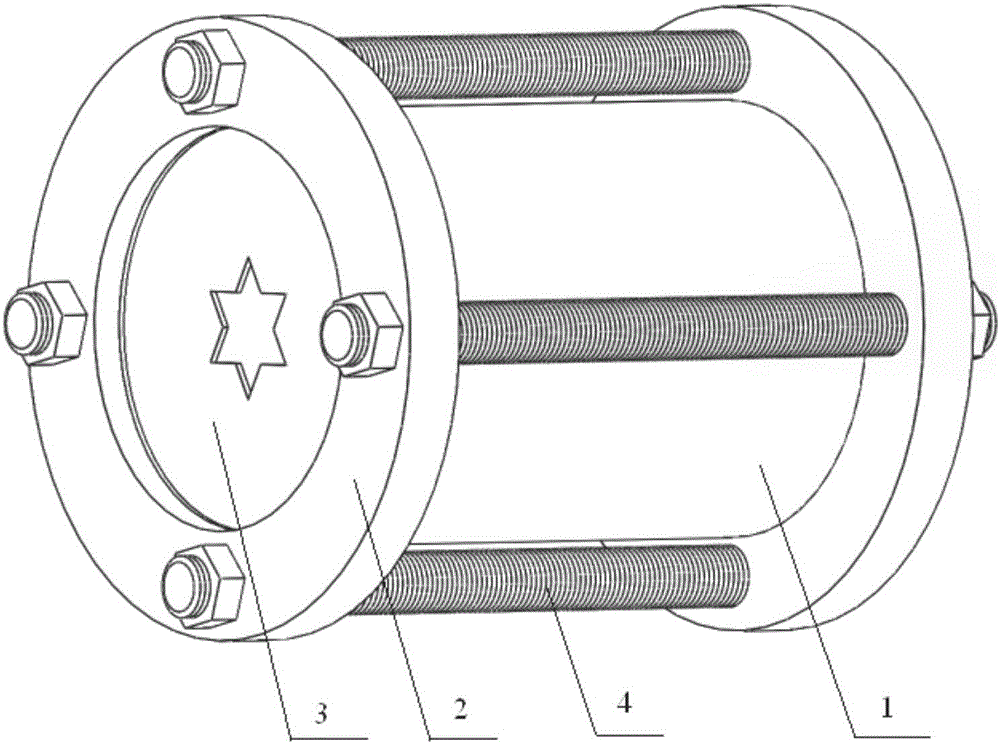

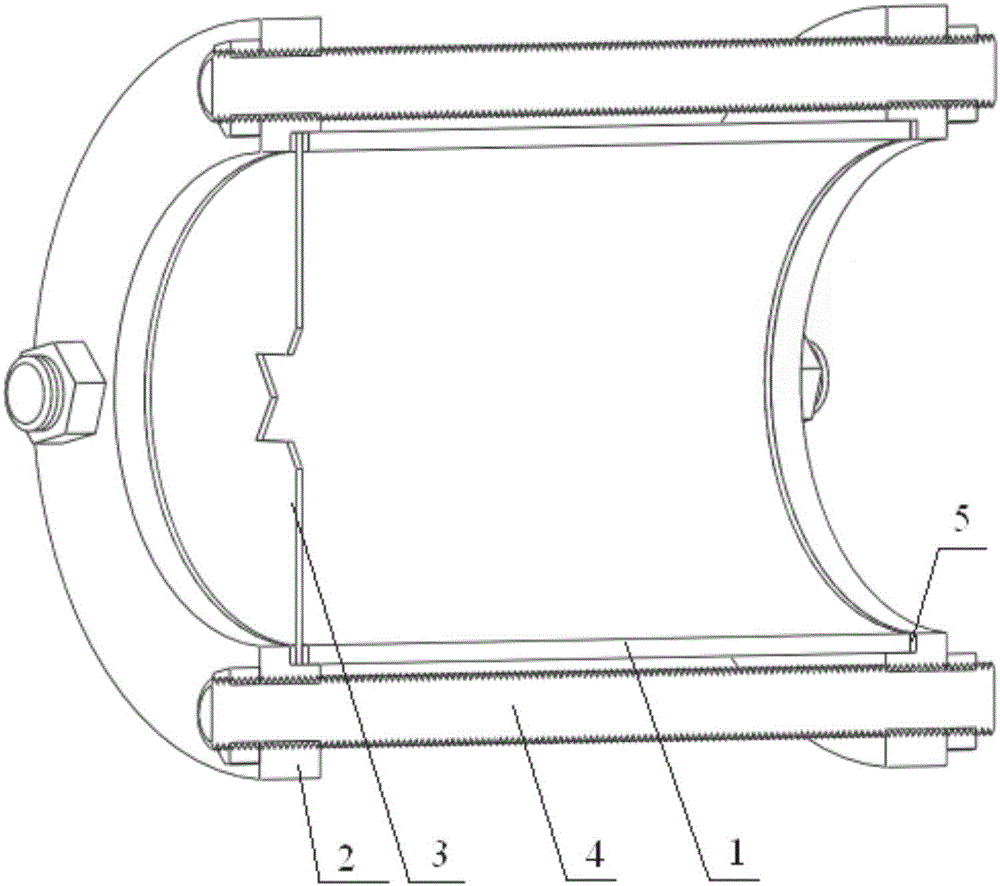

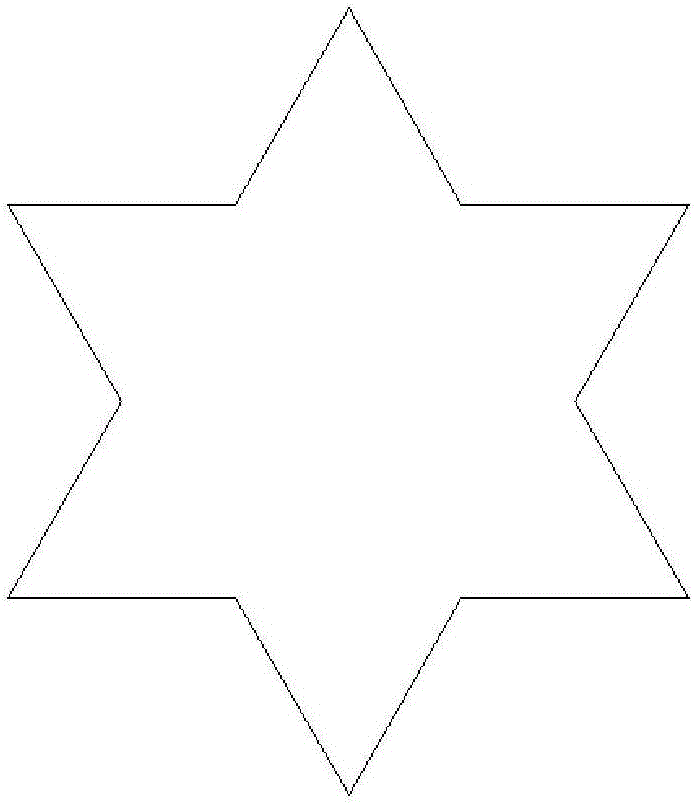

[0014] Embodiment 1: The hydraulic cavitation fractal orifice sterilization device of this embodiment includes a cylindrical tube 1, two flanges 2, a fractal orifice 3 and fastening bolts 4, the fractal orifice 3 and the cylindrical The pipe 1 is fixed in the middle of the two flanges 2, and the fractal orifice 3 is set at the water inlet end of the cylindrical pipe 1, wherein the fractal orifice 3 is formed by opening a polygonal hole at the center of the circular plate. The area is 0.9% to 1.1% of the total area of the circular plate; the fractal hole is a hexagonal star; or an equilateral triangle is made outward with the middle third of each side of the hexagonal star as the side length The obtained multi-star graphics; or a triangular shape; or a multi-rhombic graphic obtained by removing an equilateral triangle inwardly with one-third of the middle part of each side of the triangular shape as the side length.

specific Embodiment approach 2

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the hydraulic cavitation fractal orifice plate sterilization device also includes the contact surface between the flange plate 2 and the fractal orifice plate 3, the fractal orifice plate 3 and the cylindrical tube 1 between the contact surfaces, the sealing ring 5 between the flange 2 and the cylindrical tube 1 contact surface. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the area of the polygonal hole is 1% of the total area of the circular plate; other aspects are the same as Embodiment 1 or Embodiment 2.

[0017] Verify beneficial effect of the present invention with following test:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com