Forklift with cockpit rotation mechanism

A technology of the rotating mechanism and the cockpit, which is applied to the upper structure, vehicle components, and the upper structure of the truck, etc., which can solve the problems of unguaranteed maintenance space, many dead spots, and small maintenance space, so as to reduce maintenance blind spots , Large maintenance space and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

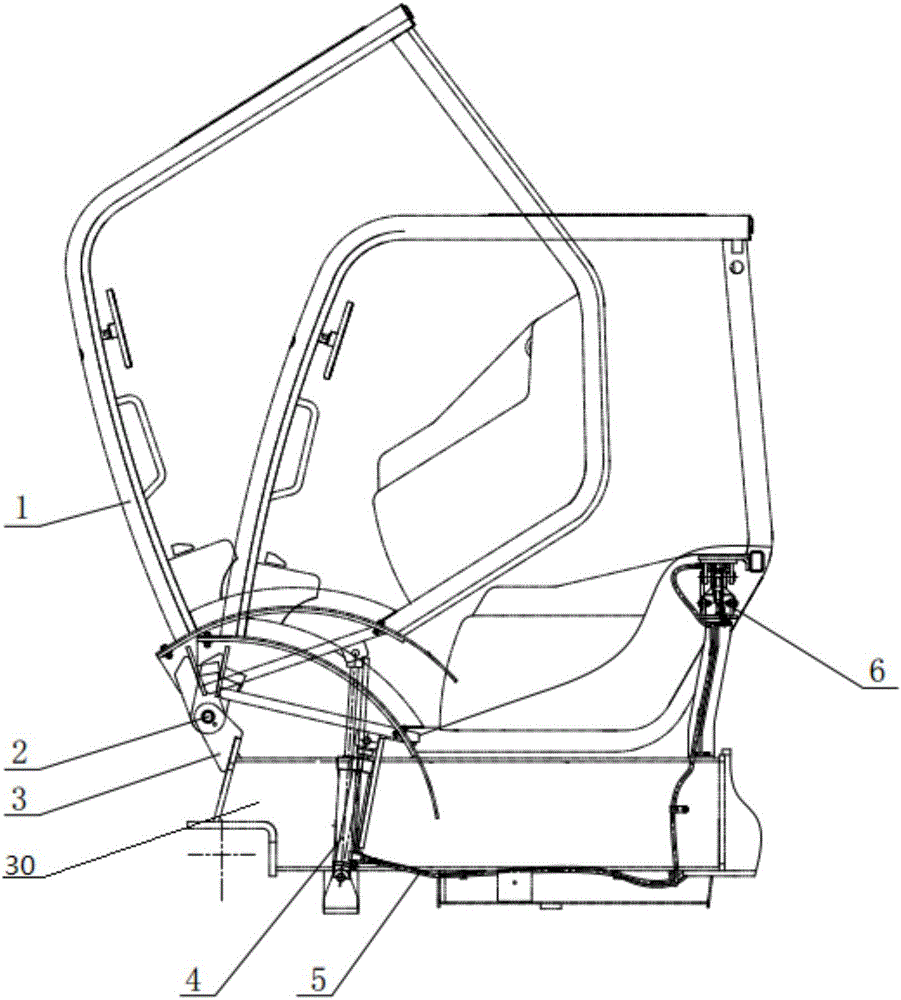

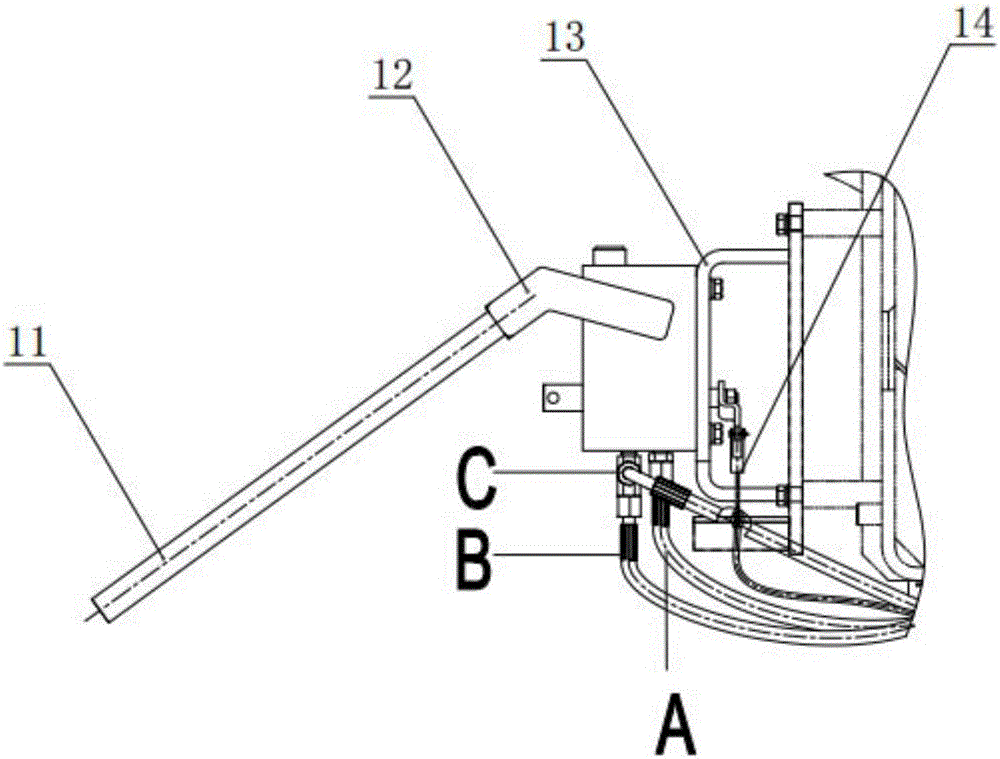

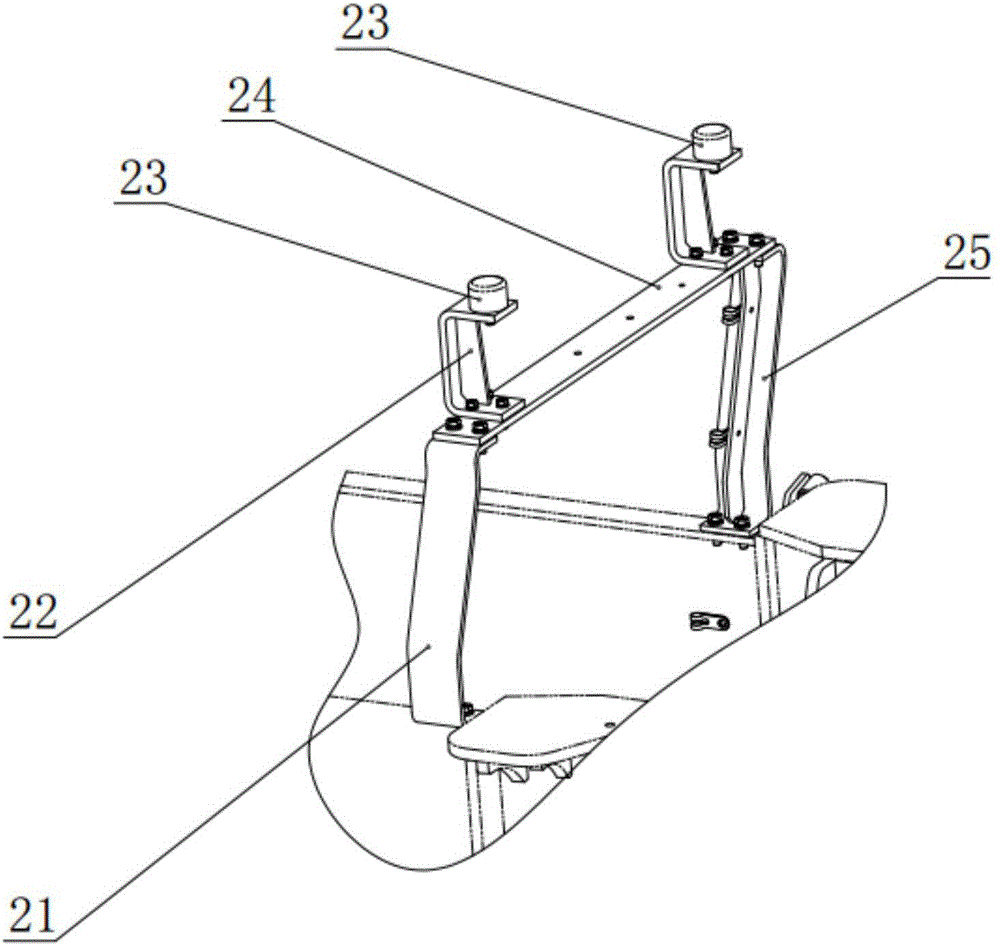

[0018] Depend on figure 1 As shown in the figure, the present invention realizes that the cab can be jacked up and put down to achieve the effect of forward tilting by tilting the joystick, swinging the joystick up and down, the oil tank supplies oil to the tilting cylinder, and the expansion and contraction of the tilting cylinder. The rotation angle depends on the stroke of the tilting cylinder, which ensures the maximum rotation of the cockpit by 32° to protect the safety of the cockpit. And after the tipping is in place, the tipping cylinder has its own cable-type mechanical protection mechanism to fully protect the safety of the user.

[0019] After the maintenance is over, it is necessary to manually operate the pull wire to release the automatic locking protection of the tilting cylinder, and repeat the up and down swing of the manual pump joystick to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com