Vehicle heat pump air conditioner with pressure sensors

A pressure sensor, heat pump air-conditioning technology, applied in vehicle components, air handling equipment, heating/cooling equipment, etc., can solve the problems of system return air with liquid, system frosting, low PTC heat transfer efficiency, etc., and achieve reliable and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

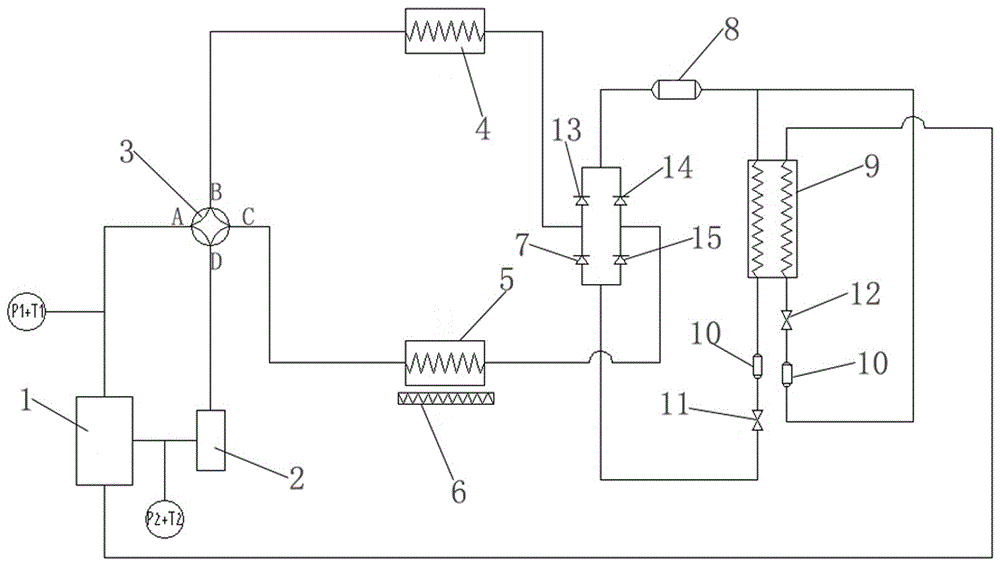

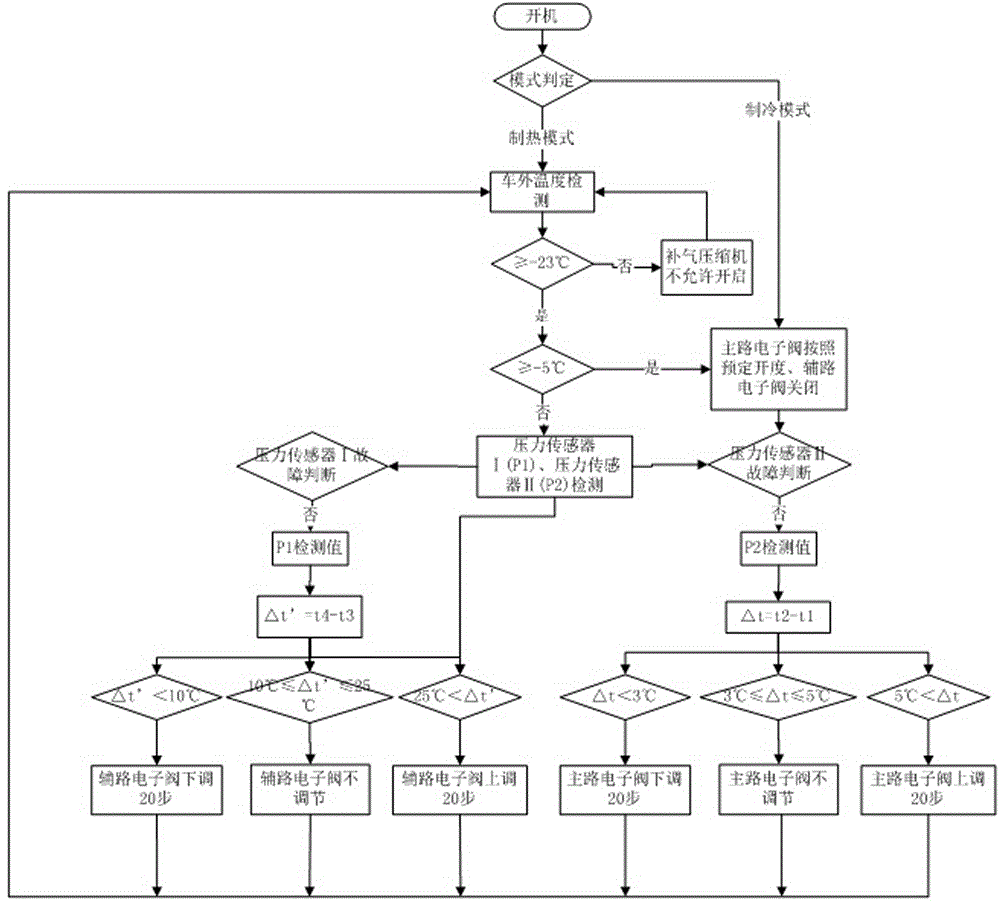

[0017] Such as figure 1 As shown, a vehicle heat pump air conditioner using a pressure sensor includes an air supply compressor 1, the exhaust port of the air supply compressor 1 is connected to the A port of the four-way valve 3, and the B port of the four-way valve 3 is connected to the outside of the vehicle. The heat exchanger 4 is connected, the other end of the external heat exchanger 4 is respectively connected with the outlet of the one-way valve I7 and the inlet of the one-way valve II13, and the first channel of the plate heat exchanger 9 is connected with the outlet of the one-way valve II13 and the one-way valve II13 respectively. The outlet of the one-way valve III14 is connected, the other end of the first channel of the plate heat exchanger 9 is connected to the main circuit electronic valve 11, and the other end of the main circuit electronic valve 11 is respectively connected to the inlet of the one-way valve I7 and the one-way valve IV15 Inlet connection, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com