Compound structure with low stress line

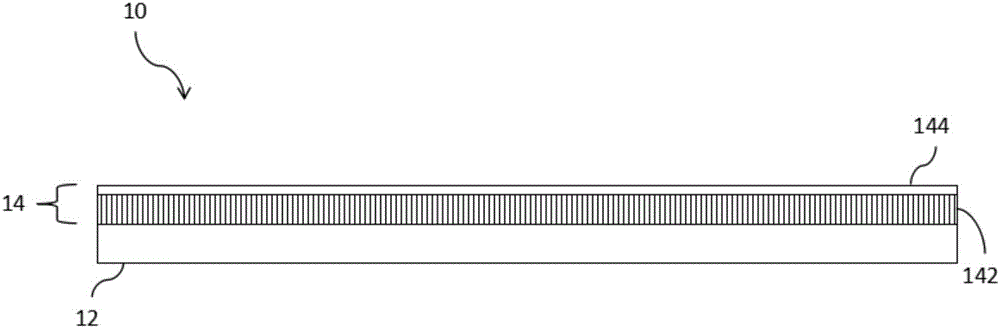

A composite structure, low stress technology, applied in the field of composite structures, can solve the problems of increased manufacturing cost, insufficient impact resistance of the cover plate structure 10, hidden safety concerns of the cover plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to improve the structural strength of the three-dimensional cover plate for vehicles, reduce stress lines, and bring about an economical manufacturing process, the present invention reveals an innovative cover plate structure to overcome the conventional deficiencies under the continuous research and careful study of the inventors. .

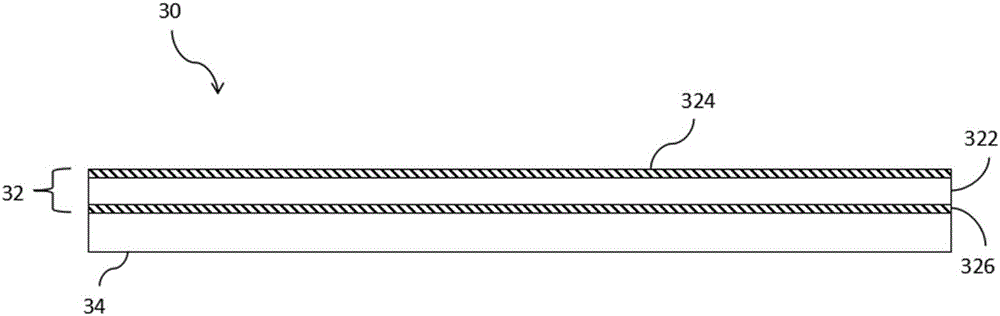

[0043] First, please refer to this invention image 3 As shown, the low-stress grain composite structure 30 of the present invention includes a composite film layer 32 and an acrylic injection layer 34 . The composite film layer 32 includes a thermoplastic material layer 322, a first acrylic hardness layer 324 and a second acrylic hardness layer 326, the thermoplastic material layer 322 has a first surface and a second surface, the first The acrylic hardness layer 324 is arranged on the first surface of the thermoplastic material layer 322, and the second acrylic hardness layer 326 is arranged on the second surface of the thermo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com