PVA (polyvinyl alcohol)-base medical antibacterial composite film

A composite film and film layer technology, applied in the field of PVA-based medical antibacterial composite film, can solve problems such as poor barrier properties, swelling of liquid pollutants, holes, etc., and achieve the effects of avoiding processes, high production efficiency, and good antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

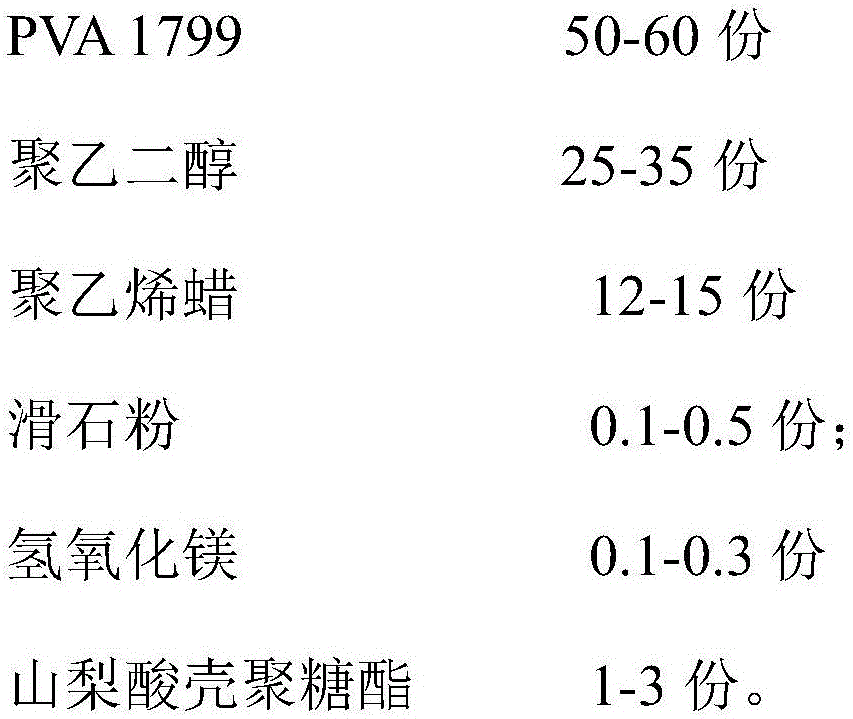

[0030] A PVA-based medical antibacterial composite film, comprising: a composite PVA film layer and a PVA needle-punched non-woven fabric layer, the PVA film layer is a blown film, the PVA film layer is a PVA double-layer composite film, and the PVA film layer includes the following components: Points and parts by weight are:

[0031]

[0032] Wherein, magnesium hydroxide and chitosan sorbate mass ratio are 1:10

[0033] Wherein, the preparation method of PVA film layer comprises the steps:

[0034] (1) PVA raw material is mixed uniformly by weight percentage, carries out melting extruding granulation with twin-screw extruder, obtains polyvinyl alcohol masterbatch;

[0035] (2) Extrusion: the polyvinyl alcohol masterbatch is sent to the extruder of the blown film machine, and the extruder is a single-screw extruder, and the diameter of the single screw is 35mm, and the rotating speed is 35r / min; The extrusion process is as follows: the temperature of the first stage is 15...

Embodiment 2

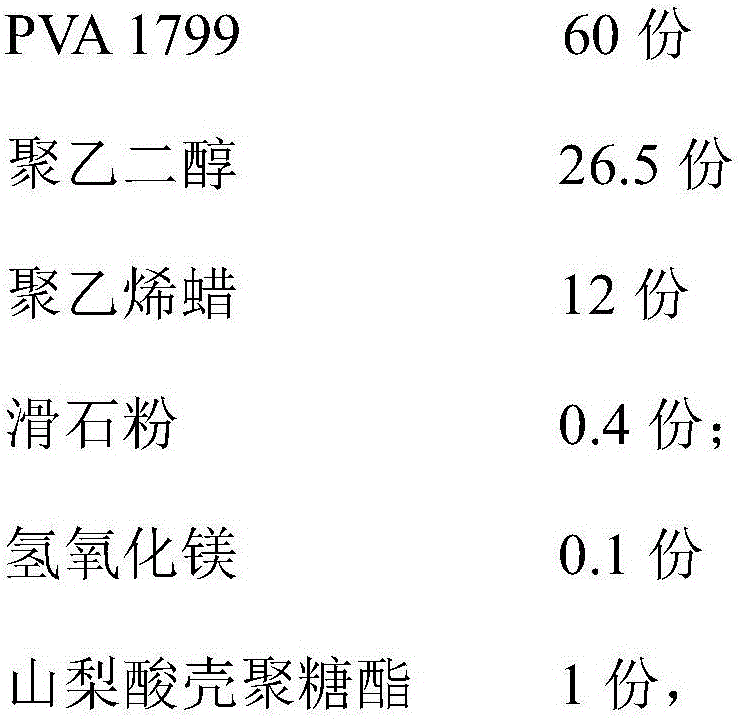

[0041] A PVA-based medical antibacterial composite film, comprising: a composite PVA film layer and a PVA needle-punched non-woven fabric layer, the PVA film layer is a blown film, the PVA film layer is a PVA double-layer composite film, and the PVA film layer includes the following components: Points and parts by weight are:

[0042]

[0043] Wherein, magnesium hydroxide and chitosan sorbate mass ratio are 1:10

[0044] Wherein, the preparation method of PVA film layer comprises the steps:

[0045] (1) PVA raw material is mixed uniformly by weight percentage, carries out melting extruding granulation with twin-screw extruder, obtains polyvinyl alcohol masterbatch;

[0046] (2) Extrusion: the polyvinyl alcohol masterbatch is sent to the extruder of the blown film machine, and the extruder is a single-screw extruder, and the diameter of the single screw is 20mm, and the rotating speed is 30r / min; The extrusion process is as follows: the temperature of the first stage is 15...

Embodiment 3

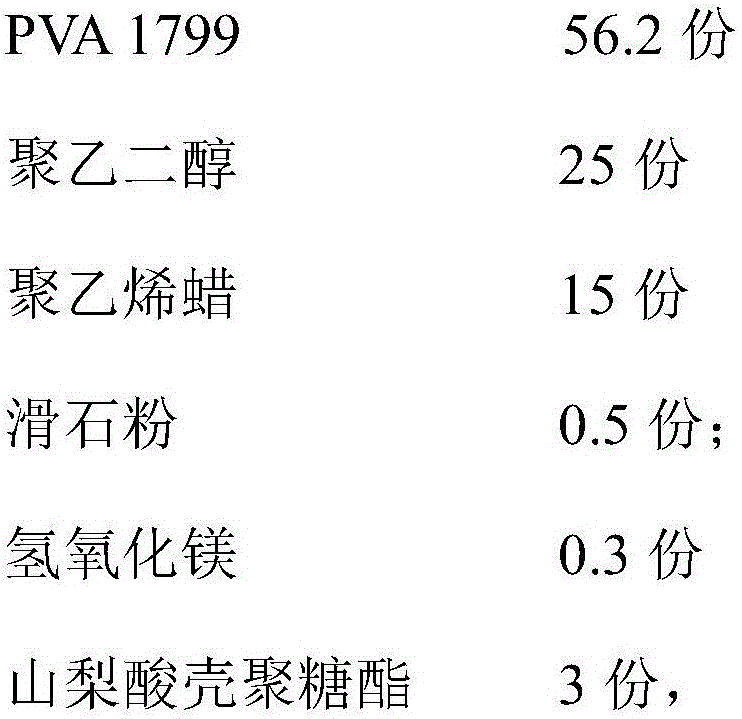

[0052] A PVA-based medical antibacterial composite film, comprising: a composite PVA film layer and a PVA needle-punched non-woven fabric layer, the PVA film layer is a blown film, the PVA film layer is a PVA double-layer composite film, and the PVA film layer includes the following components: Points and parts by weight are:

[0053]

[0054] Wherein, magnesium hydroxide and chitosan sorbate mass ratio are 1:10

[0055] Wherein, the preparation method of PVA film layer comprises the steps:

[0056] (1) PVA raw material is mixed uniformly by weight percentage, carries out melting extruding granulation with twin-screw extruder, obtains polyvinyl alcohol masterbatch;

[0057] (2) Extrusion: the polyvinyl alcohol masterbatch is sent to the extruder of the blown film machine, and the extruder is a single-screw extruder, and the diameter of the single screw is 65mm, and the rotating speed is 40r / min; The extrusion process is as follows: the temperature of the first stage is 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com