Plywood and preparation method thereof

A technology for plywood and veneer, applied in the field of plywood manufacturing, can solve the problems of increased production cost and environmental pollution treatment cost of anti-corrosion and flame-retardant plywood, the mechanical properties of plywood are difficult to meet the requirements for use, and the performance of anti-corrosion and flame retardant can not be achieved at the same time. , to achieve the effects of controllable immersion depth, less immersion drug dose, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The method for preparing plywood that the embodiment of the present application provides, such as Figure 4 As shown, can include:

[0072] Step 102: Select the veneers needed for plywood coniferous wood veneer layer 1 and plywood hardwood veneer layer 2;

[0073] Step 104: drying the selected veneer and applying adhesive;

[0074] Step 106: superimposing the veneers, pre-cold pressing and then hot pressing or curing after hot pressing;

[0075] Step 108: preparing preservatives and / or flame retardants;

[0076] Step 110: impregnating the cured slab in a preservative and / or flame retardant under vacuum or vacuum-pressurized conditions;

[0077] Step 112: drying the impregnated slab;

[0078] Step 114: maintenance.

[0079] Wherein, step 104 may be to dry the veneer to a moisture content of 3-12% by mass, and then apply adhesive on both sides, and the total coating amount of the adhesive between the veneers may be 200-12% by mass. 300g / m 2 ;

[0080] Step 106 can...

Embodiment 1

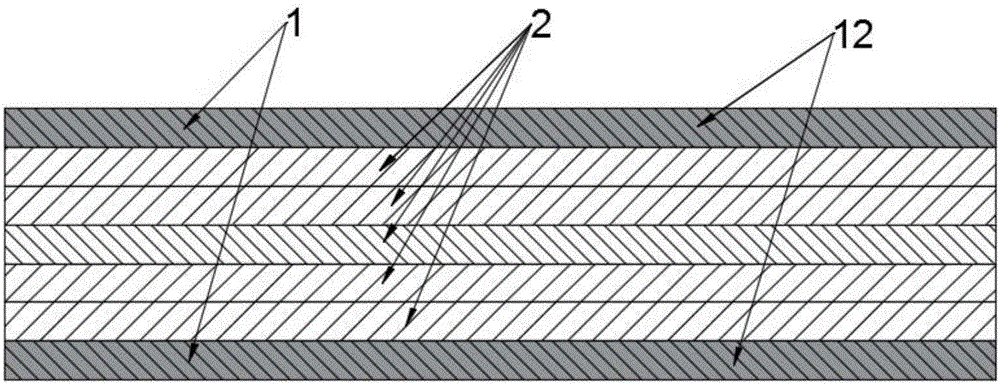

[0087] Such as figure 1 As shown, the plywood of this embodiment includes two plywood coniferous wood veneer layers 1 , five plywood broadleaf wood veneer layers 2 and two plywood anticorrosion and flame-retardant layers 12 . Among them, the surface layer of the plywood is plywood coniferous wood veneer layer 1, and the other five layers are plywood broad-leaved wood veneer layer 2, and the thickness of any single veneer layer is not less than 2mm. The wood grain direction of the plywood coniferous wood veneer layer 1 is parallel to the length direction of the plywood, the wood grain direction of the plywood hardwood veneer layer 2 in the center layer is parallel to the length direction of the plywood, and the other four plywood hardwood veneer layers 2 have the wood grain in the same direction and at a 90° angle to the length of the plywood. The veneer on the surface of the plywood contains preservatives.

[0088] Wherein, the veneer layer 1 of the plywood coniferous wood is ...

Embodiment 2

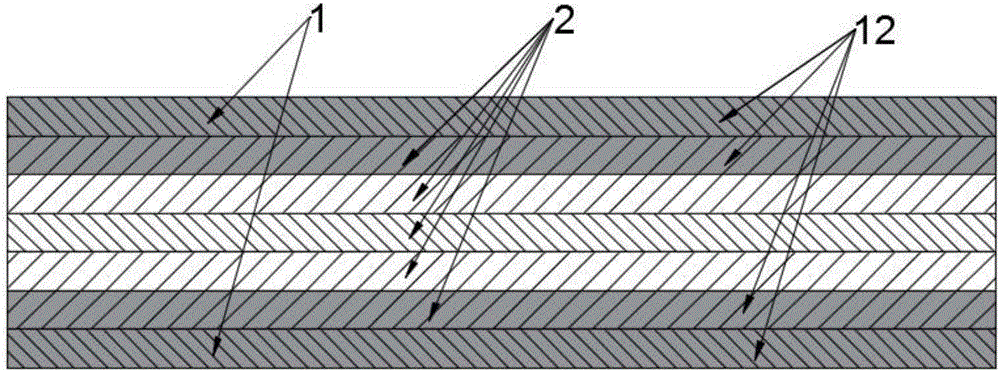

[0091] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the plywood anticorrosion and flame-retardant layer 12 has four layers, and the surface of the plywood has two layers of veneers that contain preservatives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com