Magnetic polishing device for automobile parts

A technology of auto parts and magnetic force, which is applied in the direction of grinding machines, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of low production efficiency, durability, and inability to adapt, so as to improve production efficiency, Eliminate the probability of defective products and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

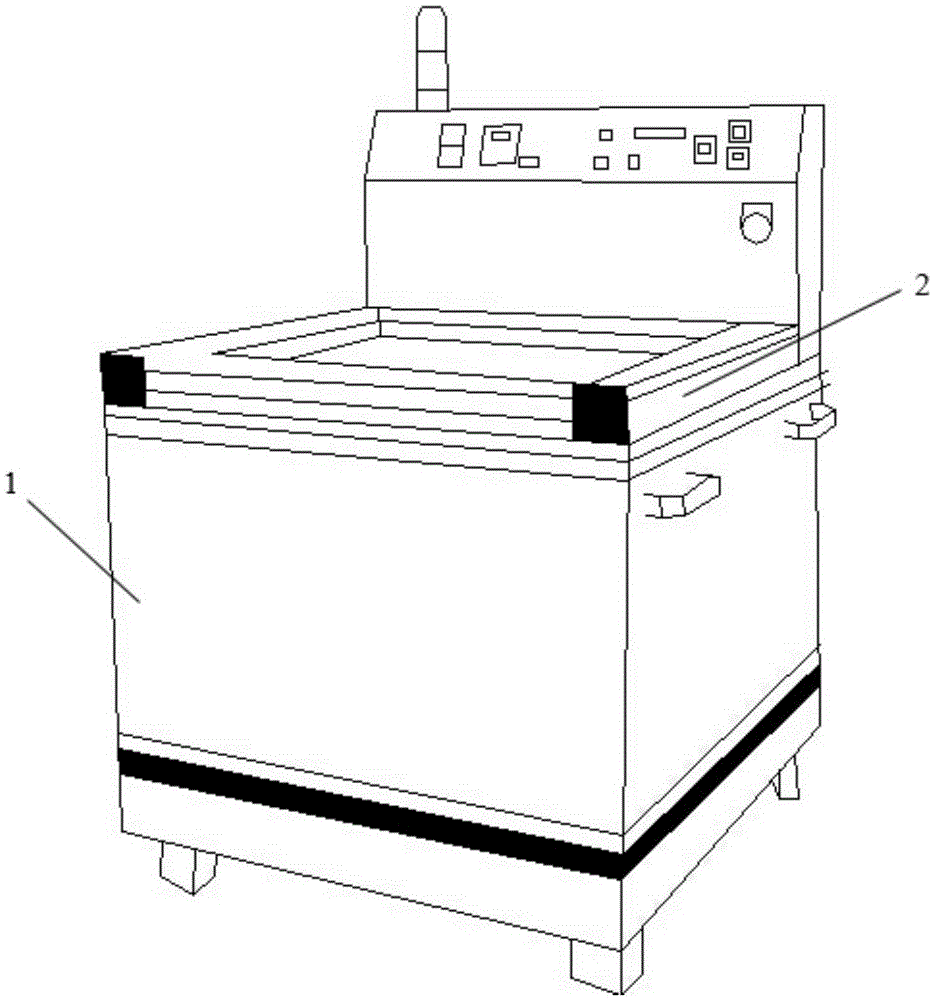

[0028] Such as figure 1 As shown, a magnetic grinding device for auto parts includes a grinding container 2, a magnetizer, a motor, a steel needle and an automatic control unit;

[0029] The grinding container 2 is placed on the bottom box 1, and several steel needles are provided and placed in the grinding container 2,

[0030] The magnetizer, motor and automatic control unit are all placed in the bottom box 1;

[0031] The automatic control unit is connected with the power supply to control the work of the magnetic grinding device for auto parts,

[0032] The magnetizer is connected to a power supply, and when the power supply is turned on, the magnetizer generates a magnetic field;

[0033] The motor is connected to the magnetizer to drive the magnetizer to move, so that the energized magnetizer generates electromagnetic force to drive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com