Vertical pouring structure for mass production of well lids

A mass production and manhole cover technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems such as low efficiency, large waste of molten iron, and dangerous handling, so as to speed up molding speed, eliminate hidden dangers in operation, and improve appearance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

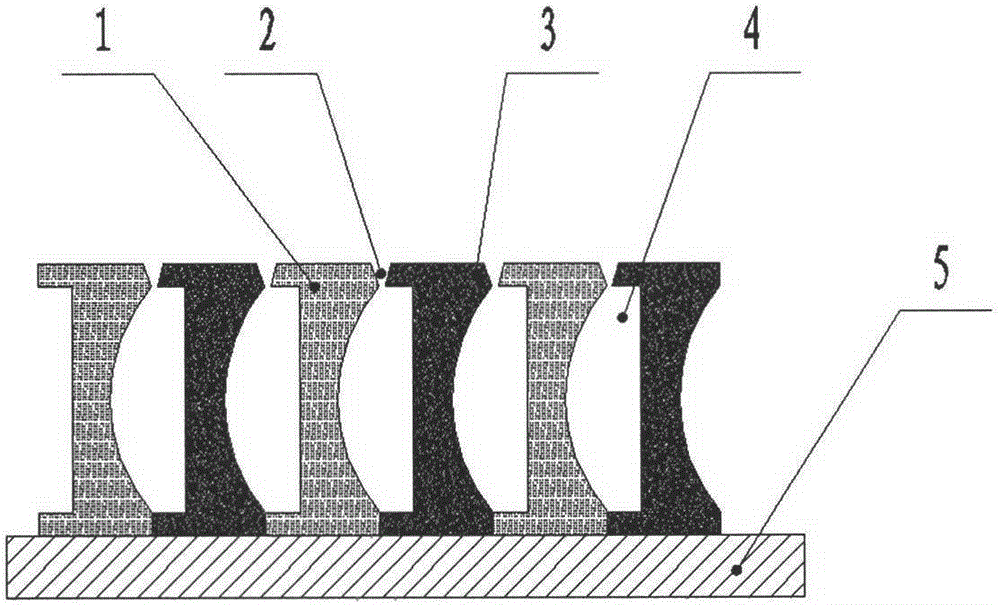

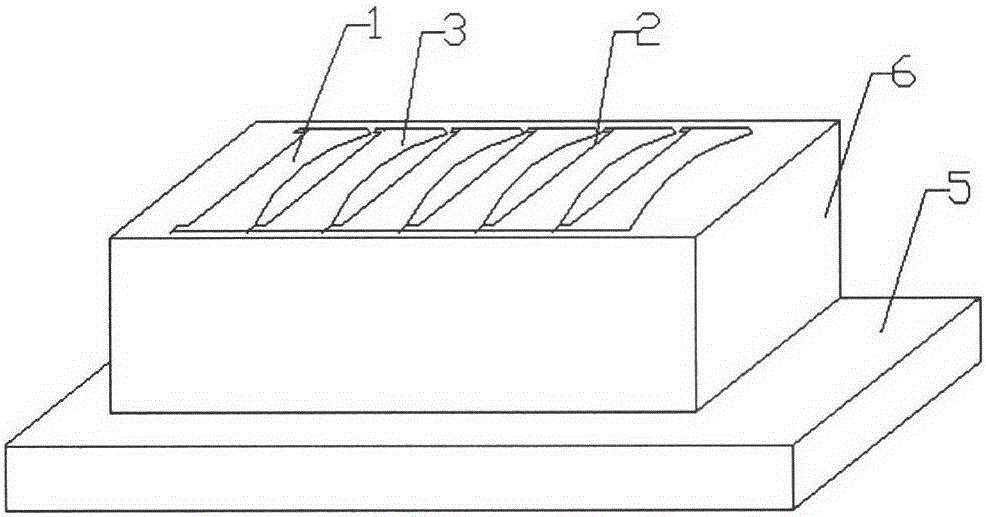

[0017] Below in conjunction with accompanying drawing, the present invention will be further described, as appended figure 1 , figure 2 As shown, firstly, the clay sand mold 3 with a size of 1200mm×1200mm and the coated sand mold 1 with a size of 1200mm×1200mm are arranged alternately and orderly, placed on the platform, and the mold cavity 4 is obtained after the mold is closed. Then cover the iron plate 6 on both sides and the facade of the sand mold to fix it, changing from "without box" operation to "with box" operation. The upper part of the cavity 4 is provided with gates 2, and each gate 2 is connected with the pouring machine, and molten iron is poured into all the cavities 4 at the same time. According to the demand of the manhole cover, determine the pouring speed, and incubate with the flow until the cavity 4 is filled. Repeat the above pouring procedure until all the cavities 4 are poured. After cooling, take out the manhole cover from the sand mold, process th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com