a pipe bending machine

A pipe bending machine and pipe bending technology, applied in storage devices, metal processing equipment, feeding devices, etc., can solve the problems of low efficiency, interference, and low precision, so as to improve service life, reduce friction damage, and improve bending quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

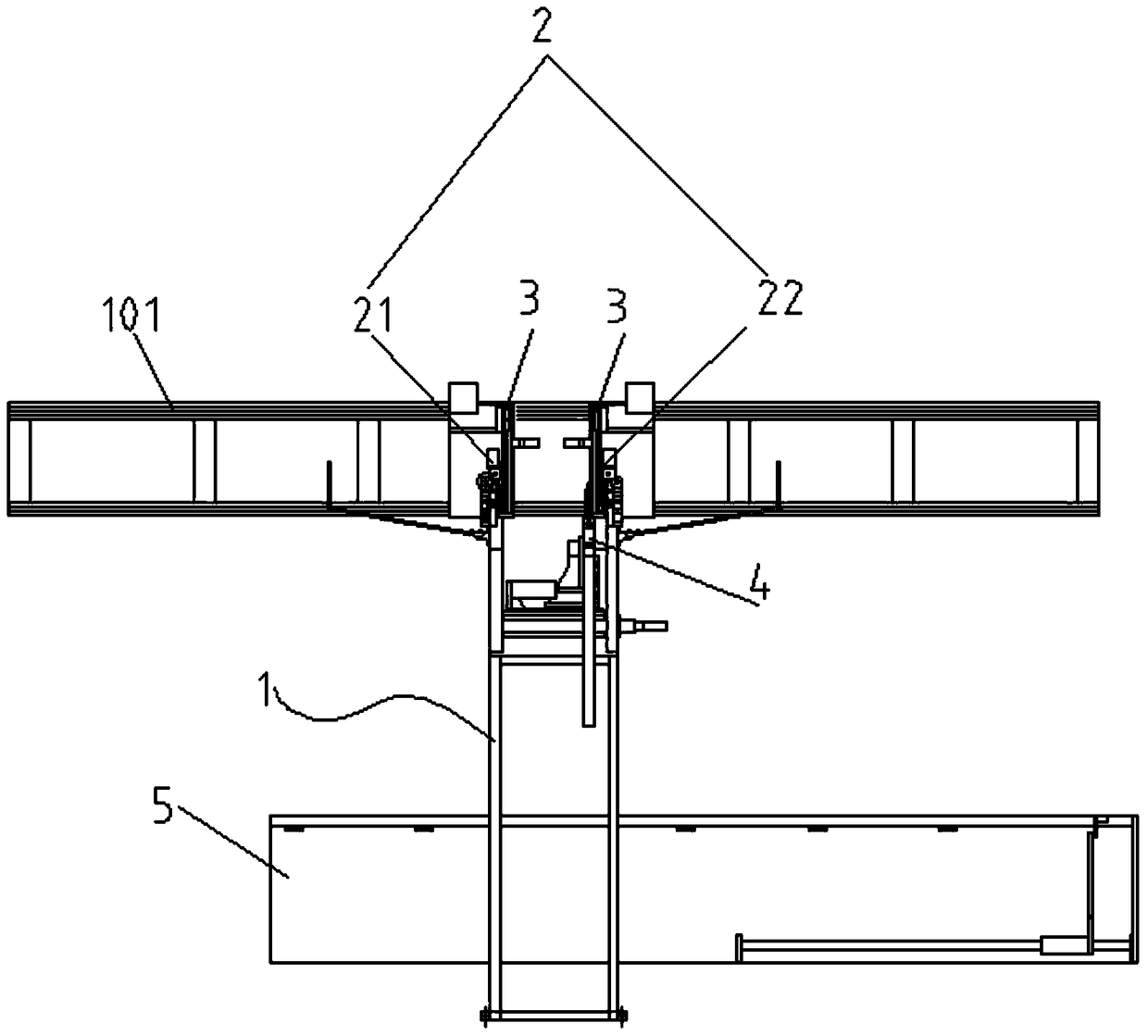

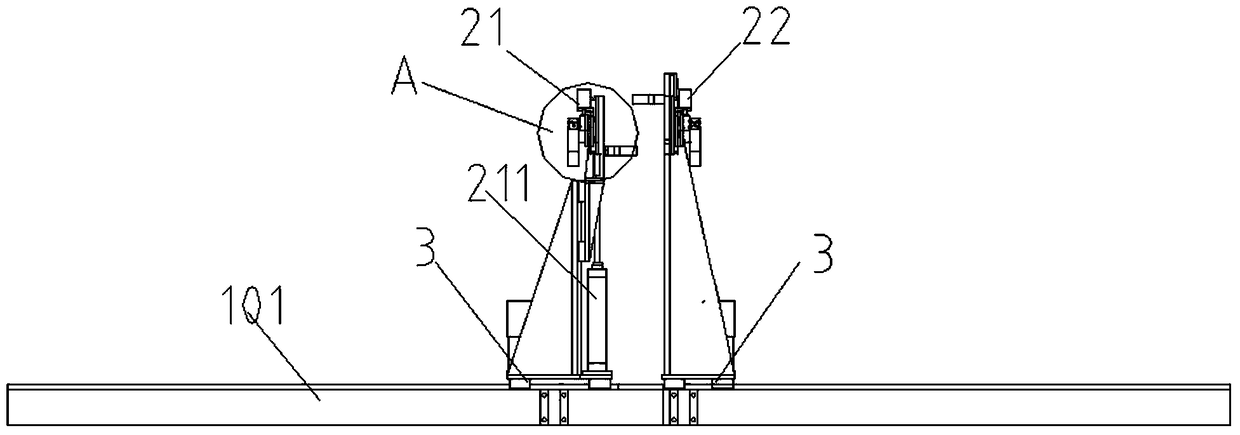

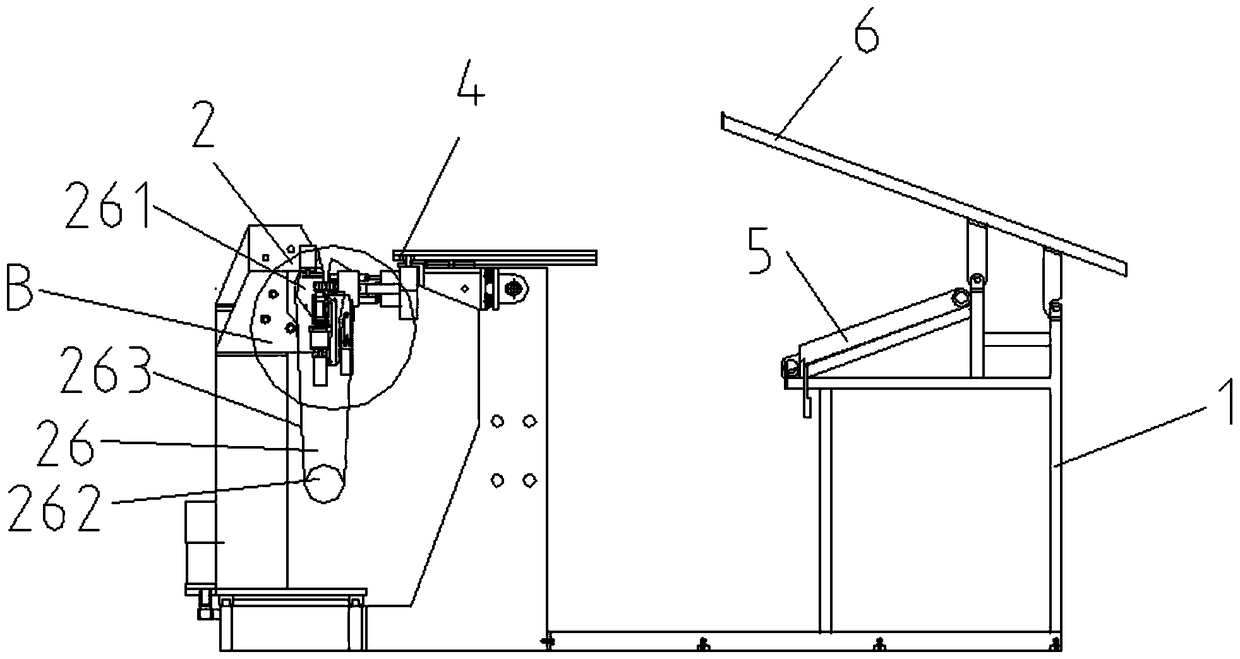

[0031] Such as Figures 1 to 9 As shown, a pipe bending machine includes a bed 1, a machine head 2, a moving seat 3, a feeding device 4, an air-controlled power system and a PLC control system. The function of moving, loading and unloading and flipping, the machine head 2 is set on the moving seat 3, the bed 1 includes a longitudinal guide rail 101, and the moving seat 3 can slide on the longitudinal guide rail 101;

[0032] The machine head 2 includes an open disc double gear transmission structure and the XY plane 180° pipe bending mechanism 24, the open disc double gear transmission structure includes an XZ plane 360° rotation mechanism 23 and a pipe re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com