Induced charge electrosmosis and dielectrophoresis based microscale particle separation chip as well as preparation method and application thereof

A particle separation and dielectrophoresis technology, applied in chemical instruments and methods, fluid controllers, laboratory containers, etc., can solve the problems of complex fluid manipulation, non-compact external equipment, etc., to improve the aggregation efficiency, simplify the structure, Easy to integrate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

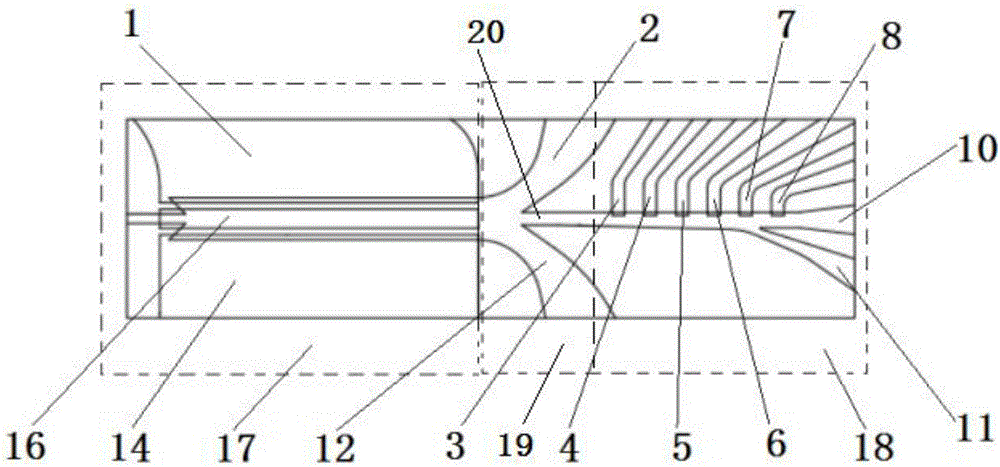

[0046] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment in detail. In this embodiment, a micro-scale particle separation chip based on induced charge electroosmosis and dielectrophoresis is composed of a PDMS cover sheet 9 and an ITO glass substrate 13; the PDMS cover sheet 9 is bonded to the ITO glass substrate 13 On the PDMS cover sheet 9, a channel is printed; the left end of the channel is provided with an inlet 15, the right end of the channel is provided with a third outlet 10, and the first outlet 2 is symmetrically arranged in the vertical direction in the middle of the channel. And the second outlet 12, the fourth outlet 11 is arranged under the side of the third outlet 10, and the outlet direction of the third outlet 10 is set at an angle of 6° with the outlet direction of the fourth outlet 11; The middle position of the passage is divided into three areas, the left side is the accumulation area 17, the right side is the sepa...

specific Embodiment approach 2

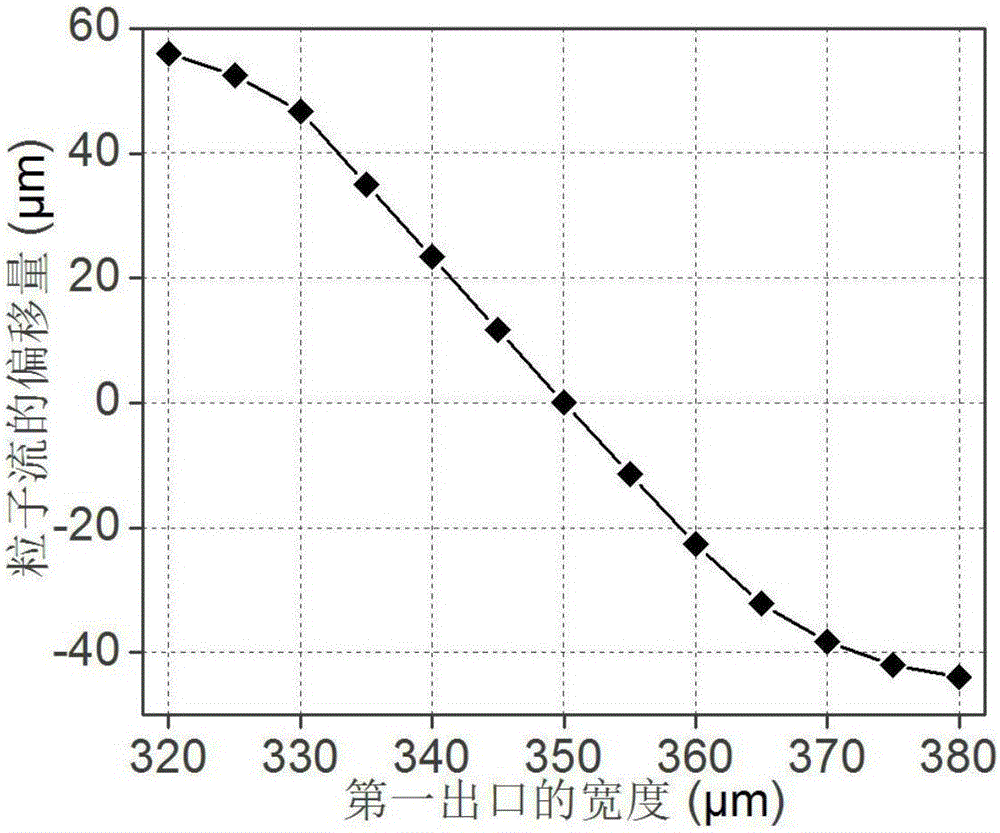

[0050] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the outlet width of the first outlet 2 is 350 microns, the outlet width of the second outlet 12 is 350 microns, and the width of the narrow entrance 20 is 200 microns. Microns. Others are the same as the first embodiment.

specific Embodiment approach 3

[0051] Specific Embodiment 3: This embodiment differs from Specific Embodiment 1 or 2 in that: the third excitation electrode 3 , the fourth excitation electrode 4 , the fifth excitation electrode 5 , the sixth excitation electrode 6 , and the seventh excitation electrode 7 The distance from the inner ends of two adjacent electrodes in the eighth excitation electrode 8 is equal. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com