A kind of cobalt oxide-doped bismuth subcarbonate/bismuth oxychloride photocatalyst and preparation method thereof

A technology of bismuth oxychloride and cobalt oxide, which is applied in the field of bismuth subcarbonate/bismuth oxychloride photocatalyst and its preparation, and can solve the problems affecting the large-scale production of photocatalysts, the limitations of large-scale production and application, and the cumbersome hydrothermal synthesis method Complicated problems, to achieve the effect of inhibiting recombination, accelerating transfer, and increasing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of cobalt oxide-doped bismuth subcarbonate / bismuth oxychloride photocatalyst preparation method of the present invention, the concrete steps of this method are as follows:

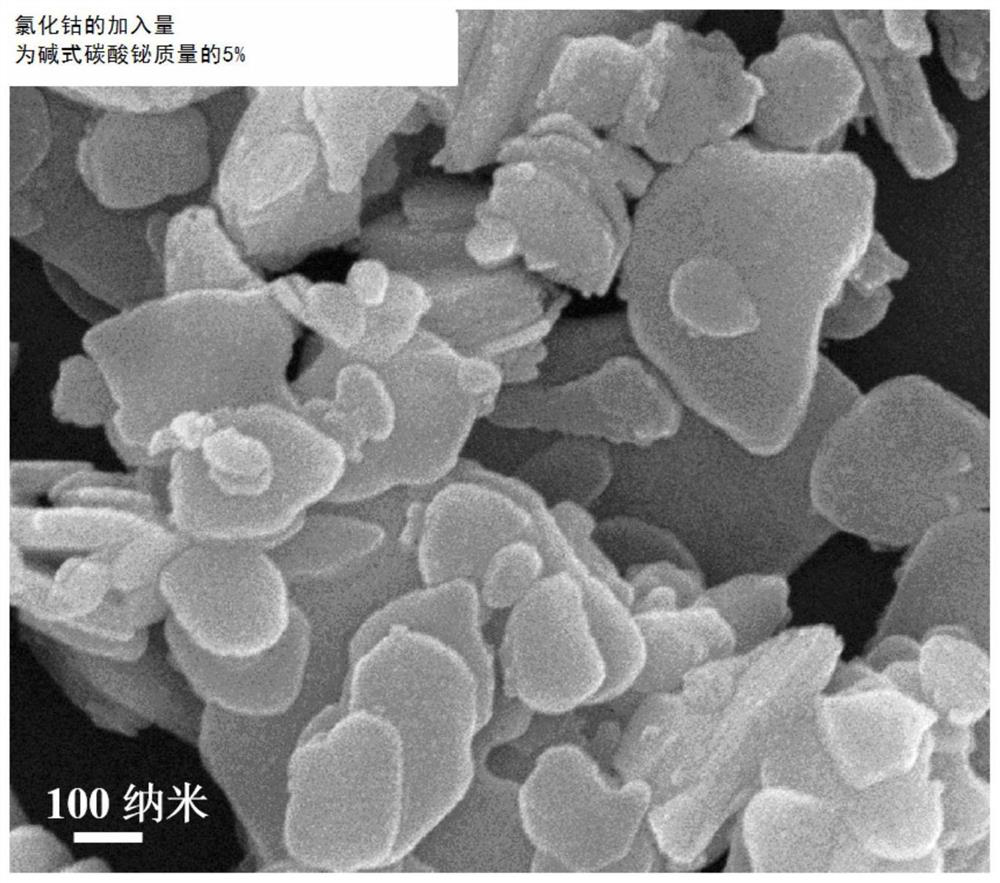

[0027] Weigh 0.05g of cobalt chloride (BiOCl) and dissolve it in 10mL of deionized water, then weigh 1.0g of bismuth subcarbonate Bi 2 o 2 CO 3 Add it into the above solution, ultrasonically disperse for 30 minutes; heat and stir at 100°C until the water is completely evaporated, grind it into powder, and then heat up to 350°C at a rate of 5°C / min and calcinate for 3 hours. After calcining, cobalt oxide doped Bismuth subcarbonate / bismuth oxychloride photocatalyst, such as figure 1 Shown, the specification model of described bismuth subcarbonate is CAS 5892-10-4 (produced by Aladdin Biochemical Technology Co., Ltd.); the specification model of cobalt chloride is CAS 7791-13-1 (Aladdin Biochemical Technology Co., Ltd. Ltd.).

Embodiment 2

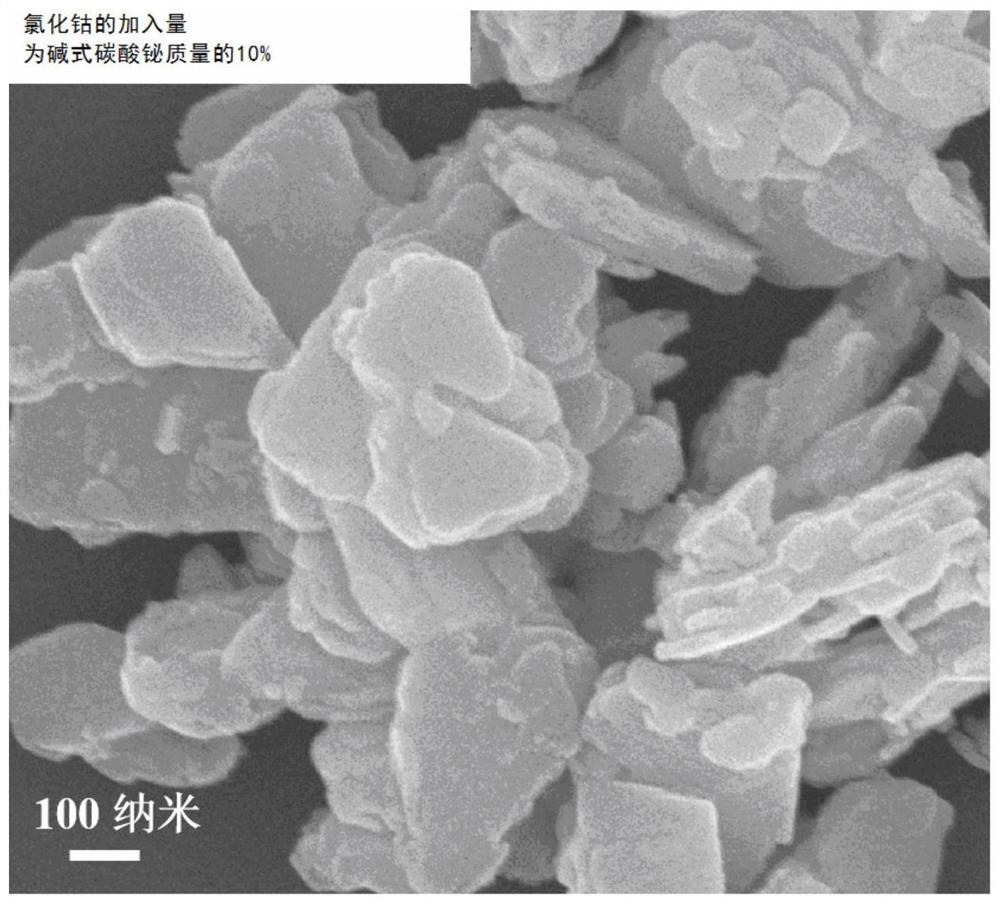

[0029] The present embodiment 2 is basically the same as embodiment 1, the difference is that the cobalt chloride weighing 0.1g described in the above step (1) is added to 10mL deionized water to obtain cobalt oxide doped bismuth subcarbonate / bismuth oxychloride photocatalyst, such as figure 2 shown

Embodiment 3

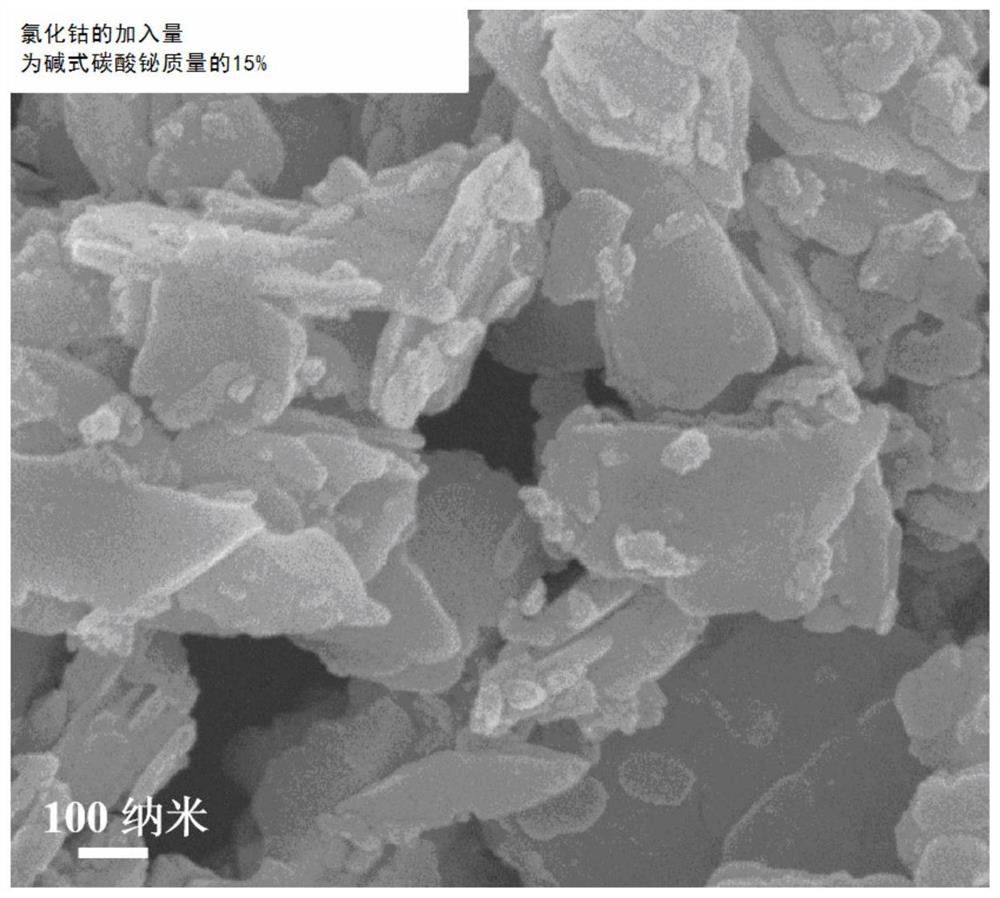

[0031] The present embodiment 3 is basically the same as embodiment 1, except that the cobalt chloride weighed 0.15g described in the above step (1) is added to 10mL deionized water to obtain cobalt oxide doped bismuth subcarbonate / bismuth oxychloride photocatalyst, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com