Ultrathin zeolite imidazate skeleton hybrid membrane, preparation method and application thereof

A zeolite imidazolate and hybrid membrane technology, which is applied in the field of membrane separation, can solve the problems of poor membrane performance, poor compatibility between inorganic materials and organic substances, and achieve good repeatability, good gas separation performance, and good interface compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Zn 2 (bim) 4 Preparation of Nanosheet @OPBI Hybrid Membrane Ⅰ:

[0029] ① Add Zn 2 (bim) 4 Nanosheets dispersed in methanol to form a dispersion, Zn 2 (bim) 4 The nanosheet concentration was 0.04 mg / mL.

[0030] ② Dissolve OPBI in N,N-dimethylacetamide to prepare a polymer solution with a concentration of 0.05 wt%.

[0031] ③α-Al 2 o 3 The porous carrier was placed on a heating platform at 120°C, and the Zn 2 (bim) 4 The nanosheet / methanol dispersion was dropped on its surface drop by drop (with 5.9mL dispersion / cm 2 carrier), and dried for 1 hour.

[0032] ④ Transfer the carrier to the platform at room temperature, add OPBI polymer solution drop by drop (at 0.024mL polymer solution / cm 2 carrier), dried at 70°C for one hour,

[0033] ⑤Repeat steps ③ and ④ for 2 drops to make film.

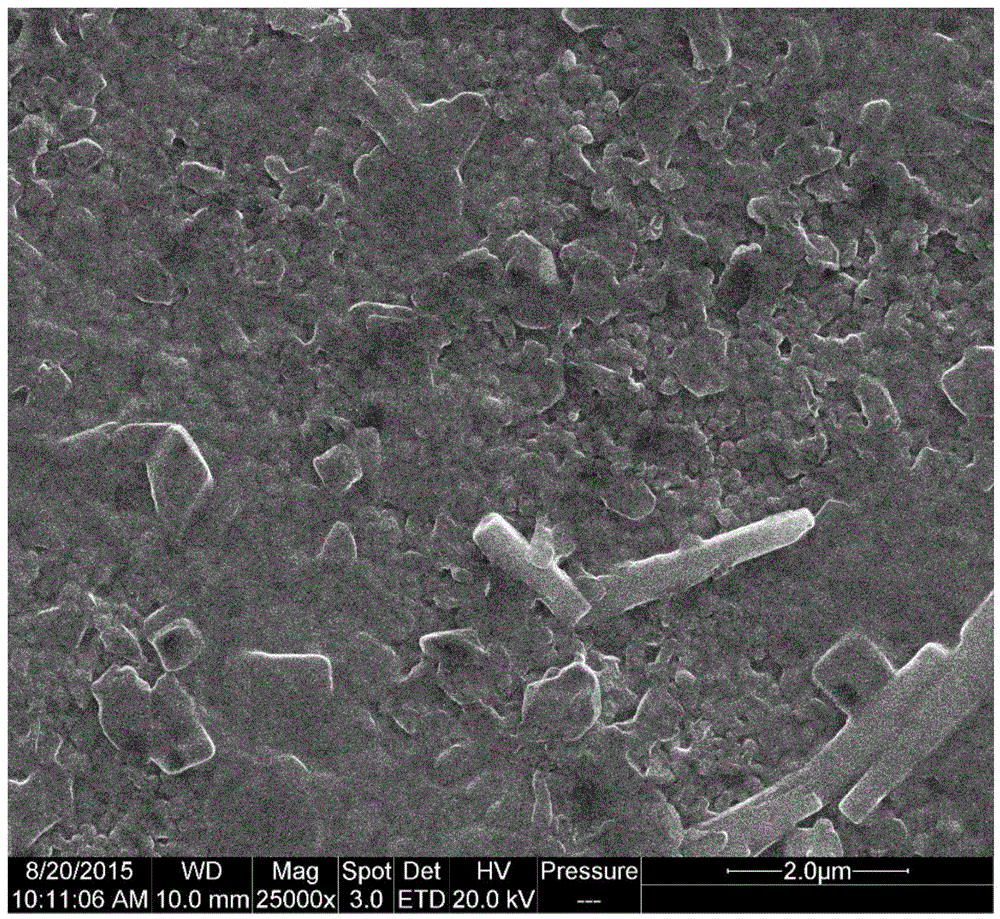

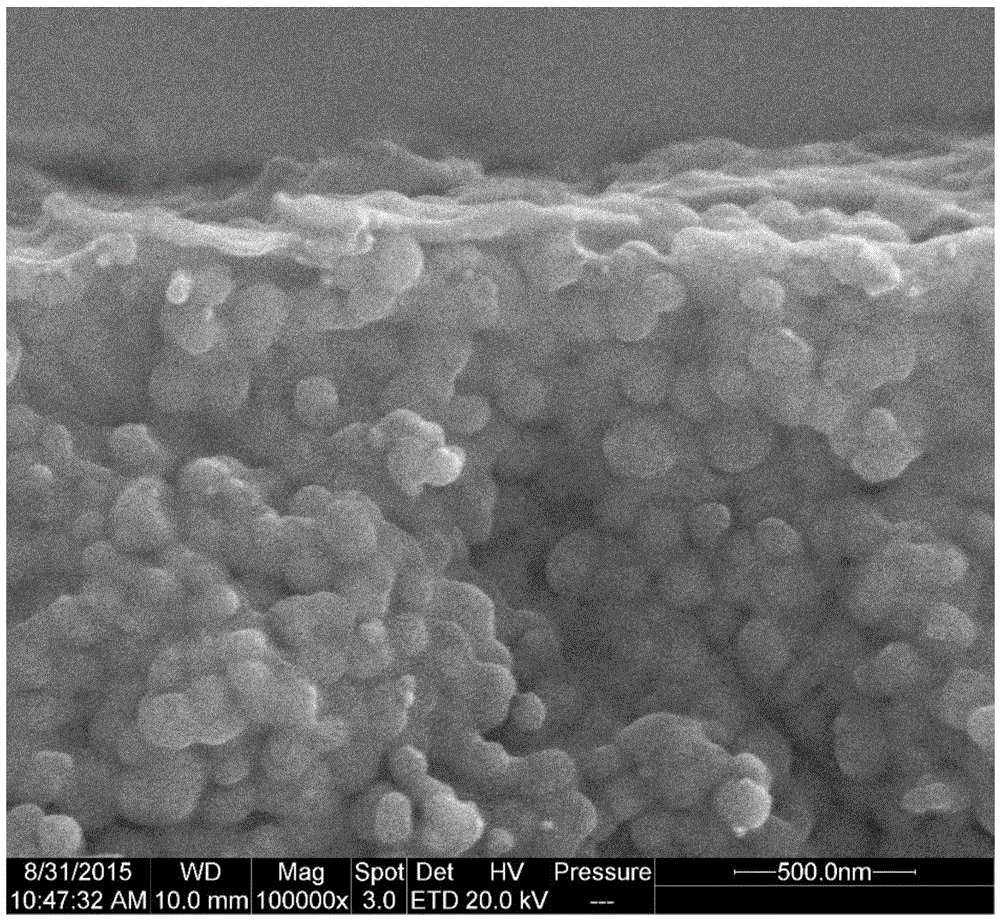

[0034] Scanning electron micrographs ( figure 1 ) shows that the polymer layer is very thin, and the morphology of the nanosheets can be clearly seen. The scanning electron m...

Embodiment 2-3

[0036] According to the same method in Example 1, two repeated parallel experiments were carried out, and two Zn 2 (bim) 4 Nanosheet @OPBI hybrid membranes are numbered hybrid membrane i, hybrid membrane ii and hybrid membrane iii, respectively.

Embodiment 4

[0038] Zn 2 (bim) 4 Preparation of Nanosheet@OPBI Hybrid Membrane Ⅱ

[0039] ① Add Zn 2 (bim) 4 Nanosheets dispersed in methanol to form a dispersion, Zn 2 (bim) 4 The nanosheet concentration was 0.04 mg / mL.

[0040]② Dissolve OPBI in N,N-dimethylacetamide to prepare a polymer solution with a concentration of 0.02wt%.

[0041] ③ Zn 2 (bim) 4 The nanosheet / methanol dispersion was added dropwise on α-Al at 120 °C 2 o 3 Porous carrier surface (with 5.9mL dispersion / cm 2 Carrier), dried at 60°C for 12 hours, and dried at 60°C under vacuum for 12 hours.

[0042] ④ Pull a thin layer of polymer solution on the surface of the alumina carrier loaded with nanosheets by dipping and pulling. Number of pulls: 1 time, then the film was dried at room temperature for 48 hours, transferred to a 70°C oven for 12 hours, 150°C for 12 hours, and 150°C for 12 hours under vacuum.

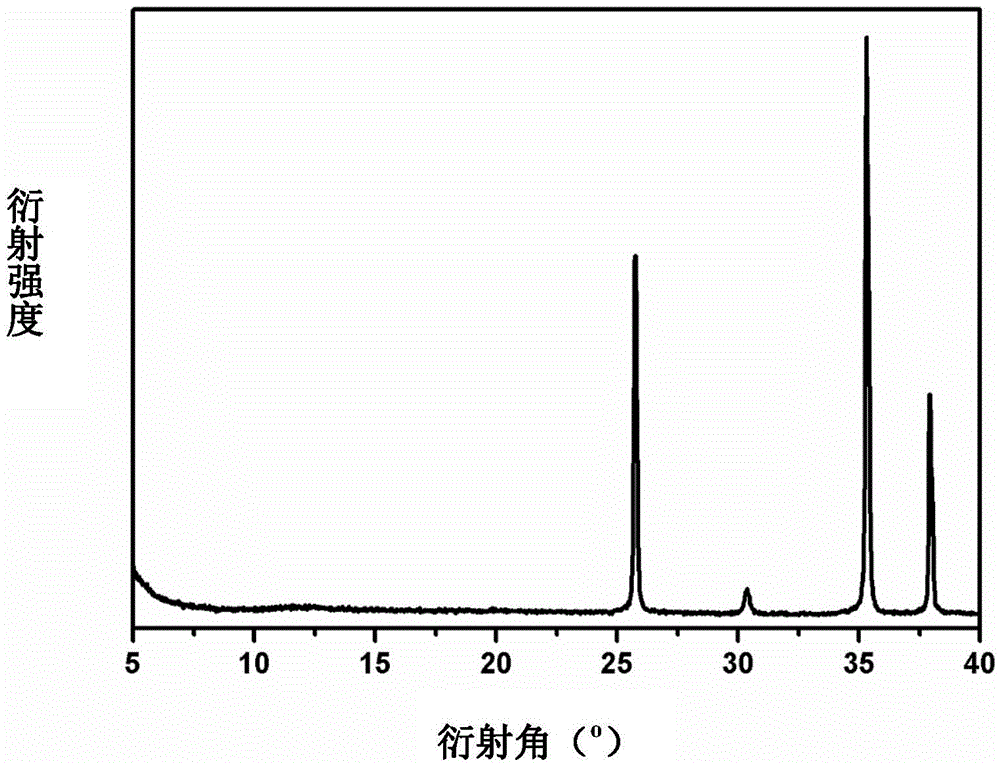

[0043] X-ray diffraction spectrum ( Figure 4 ) The peak near 9° is the characteristic peak of nanosheets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com