Automatic powder spraying firefighting device used in mining area

A fire extinguishing device and mine-used technology, which is applied in fire rescue and other fields, can solve the problems of low fire extinguishing ability, reduced fire extinguishing ability, high suspension, etc., and achieve the effect of improving fire extinguishing efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

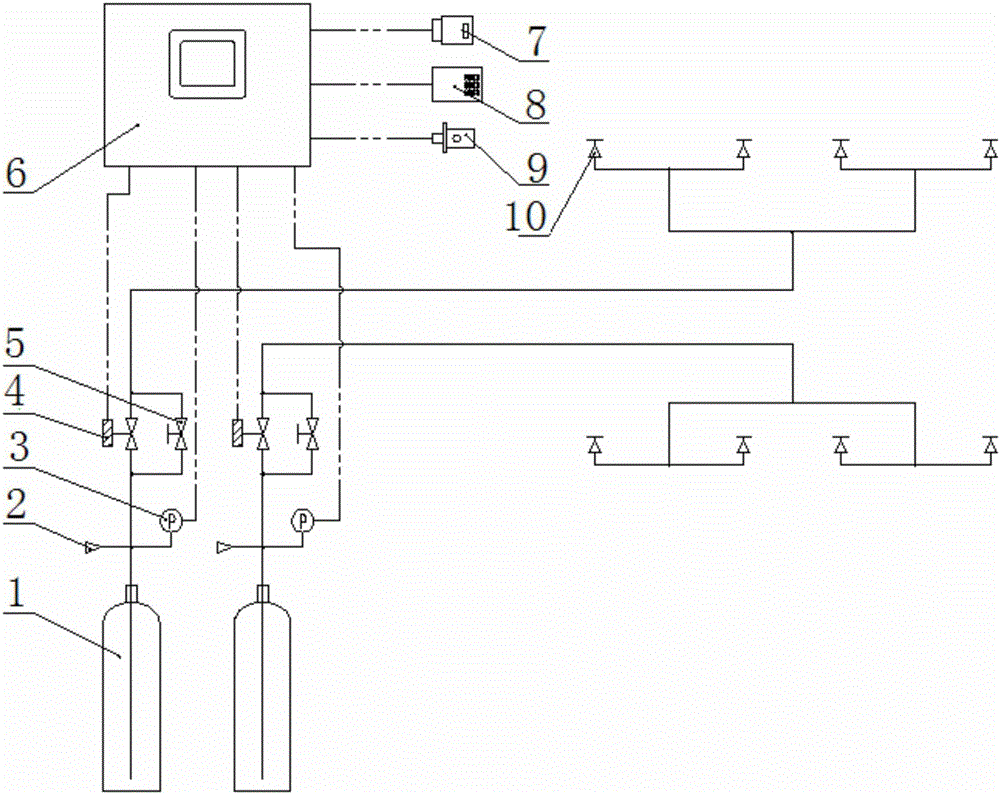

[0020] This embodiment provides an automatic powder spraying fire extinguishing device for a mining area, which is characterized in that: the automatic powder spraying fire extinguishing device for a mining area includes a pressure storage type ABC ultrafine dry powder fire extinguishing gas cylinder 1, a one-way valve 2, Mine intrinsically safe pressure transmitter 3, mine intrinsically safe solenoid valve 4, manual valve 5, ZFM6 / 10-K mining area automatic powder spraying fire extinguishing device controller 6, mine intrinsically safe sound and light alarm 7. Mine smoke sensor 8, mine intrinsically safe flame sensor 9, nozzle 10;

[0021] Among them: pressure storage type ABC superfine dry powder fire extinguishing gas cylinder 1 is connected to sprinkler head 10 through check valve 2, mining intrinsically safe solenoid valve 4 and manual valve 5; ZFM6 / 10-K mining area automatic powder spraying fire extinguishing device is controlled The controller 6 is respectively connected...

Embodiment 2

[0026] This embodiment provides an automatic powder spraying fire extinguishing device for a mining area, which is characterized in that: the automatic powder spraying fire extinguishing device for a mining area includes a pressure storage type ABC ultrafine dry powder fire extinguishing gas cylinder 1, a one-way valve 2, Mine intrinsically safe pressure transmitter 3, mine intrinsically safe solenoid valve 4, manual valve 5, ZFM6 / 10-K mining area automatic powder spraying fire extinguishing device controller 6, mine intrinsically safe sound and light alarm 7. Mine smoke sensor 8, mine intrinsically safe flame sensor 9, nozzle 10;

[0027] Among them: pressure storage type ABC superfine dry powder fire extinguishing gas cylinder 1 is connected to sprinkler head 10 through check valve 2, mining intrinsically safe solenoid valve 4 and manual valve 5; ZFM6 / 10-K mining area automatic powder spraying fire extinguishing device is controlled The controller 6 is respectively connected...

Embodiment 3

[0032] This embodiment provides an automatic powder spraying fire extinguishing device for a mining area, which is characterized in that: the automatic powder spraying fire extinguishing device for a mining area includes a pressure storage type ABC ultrafine dry powder fire extinguishing gas cylinder 1, a one-way valve 2, Mine intrinsically safe pressure transmitter 3, mine intrinsically safe solenoid valve 4, manual valve 5, ZFM6 / 10-K mining area automatic powder spraying fire extinguishing device controller 6, mine intrinsically safe sound and light alarm 7. Mine smoke sensor 8, mine intrinsically safe flame sensor 9, nozzle 10;

[0033] Among them: pressure storage type ABC superfine dry powder fire extinguishing gas cylinder 1 is connected to sprinkler head 10 through check valve 2, mining intrinsically safe solenoid valve 4 and manual valve 5; ZFM6 / 10-K mining area automatic powder spraying fire extinguishing device is controlled The controller 6 is respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com