Fermented orange peel jam powder

A technology of orange peel and orange peel, which is applied in food science, food preservation, food ingredients as taste improvers, etc. It can solve the problems of increased production costs, inconvenient packaging and transportation, and large resources, so as to save costs and facilitate transportation and storage, enhance the effect of health function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

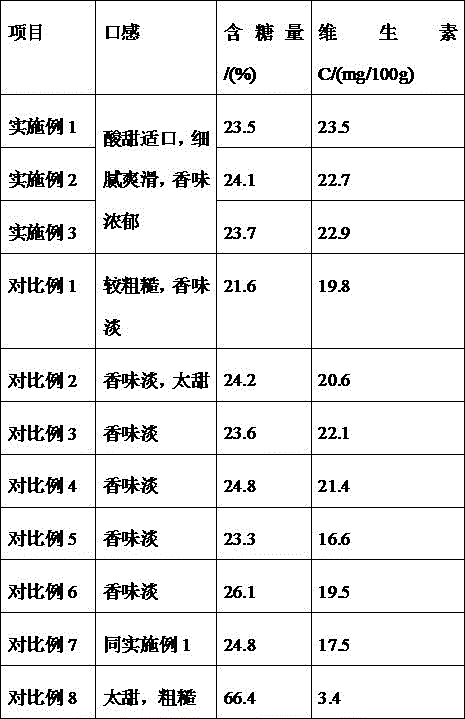

Image

Examples

Embodiment 1

[0020] A fermented orange peel sauce powder, made from the following raw materials in parts by weight: orange peel 96, konjac starch 16, corn starch 12, bifidobacterium 2, bacillus subtilis 2, angelic brewer's yeast 2, soybean oligosaccharide 7 , ε-polylysine 0.04, white willow bark extract 0.5, Ditang flower extract 0.5.

[0021] Described orange peel is fresh orange peel.

[0022] The white willow bark extract is prepared by washing the white willow bark, crushing it to 60 mesh, adding an alcohol solution with a volume fraction of 64% in an amount 40 times the weight of the white willow bark, ultrasonicating at 33kHz for 40 minutes, heating and concentrating to the original volume 1 / 15, filtered, and the filtrate was dried to obtain the white willow bark extract.

[0023] The said Ditang flower extract is to wash and crush the Ditang flower, add water with 70 times the weight of Di Tang flower, heat and boil, soak for 20 minutes, continue to heat and concentrate until the v...

Embodiment 2

[0033] A fermented orange peel sauce powder, made of the following raw materials in parts by weight: orange peel 97, konjac starch 17, corn starch 13, bifidobacterium 2.5, bacillus subtilis 2.5, angelic brewer's yeast 2.5, soybean oligosaccharide 8 , ε-polylysine 0.05, white willow bark extract 0.6, Ditang flower extract 0.6.

[0034] Described orange peel is fresh orange peel.

[0035] The white willow bark extract is to wash the white willow bark, crush it to 60 mesh, add an alcohol solution with a volume fraction of 65% in an amount 45 times the weight of the white willow bark, ultrasonicate at 34kHz for 45 minutes, heat and concentrate until the volume is the original 1 / 15, filtered, and the filtrate was dried to obtain the white willow bark extract.

[0036] The said Ditang flower extract is to wash and crush the Ditang flower, add water with 75 times the weight of Di Tang flower, heat and boil, soak for 20-25 minutes, continue to heat and concentrate until the volume is...

Embodiment 3

[0039] A fermented orange peel sauce powder, which is made of the following raw materials in parts by weight: orange peel 98, konjac starch 18, corn starch 14, bifidobacterium 3, bacillus subtilis 3, angel yeast cerevisiae 3, soybean oligosaccharide 9 , ε-polylysine 0.06, white willow bark extract 0.7, Ditang flower extract 0.7.

[0040] Described orange peel is fresh orange peel.

[0041] The white willow bark extract is to wash the white willow bark, crush it to 80 mesh, add an alcohol solution with a volume fraction of 66% in an amount 50 times the weight of the white willow bark, ultrasonicate at 35kHz for 50 minutes, heat and concentrate until the volume is the original 1 / 15, filtered, and the filtrate was dried to obtain the white willow bark extract.

[0042] The said Ditang flower extract is to wash and crush the Ditang flower, add water with 80 times the weight of Di Tang flower, heat and boil, soak for 20-25 minutes, continue heating and concentrating until the volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com