Water-soluble plant essential oil feed additive and preparation method thereof

The technology of a feed additive and plant essential oil is applied in the field of water-soluble plant essential oil feed additive and its preparation, which can solve the problems of low solubility, inability to be widely used, poor effect, etc. The effect of germs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of water-soluble plant essential oil feed additive, by weight percentage, its formula is:

[0020] Cinnamaldehyde 16%, thymol 19%, eugenol 4%, carvacrol 10%, emulsifier propylene glycol 2%, purified water 49%.

[0021] The preparation method of the water-soluble plant essential oil feed additive comprises the following steps:

[0022] 1) Mix cinnamaldehyde, thymol, eugenol, and carvacrol according to the above weight ratio, and fully stir to obtain a semi-finished plant essential oil;

[0023] 2) Mix the obtained plant essential oil semi-finished product with emulsifier propylene glycol, and use a high-speed homogenizer for stirring. The speed of the high-speed homogenizer is 24000r / min, and the homogenization time is 8-10min, so that it is fully emulsified;

[0024] 3) Add the emulsified plant essential oil semi-finished product into solvent water and stir well to obtain a finished product. The weight percentage of the plant essential oil in the finished produc...

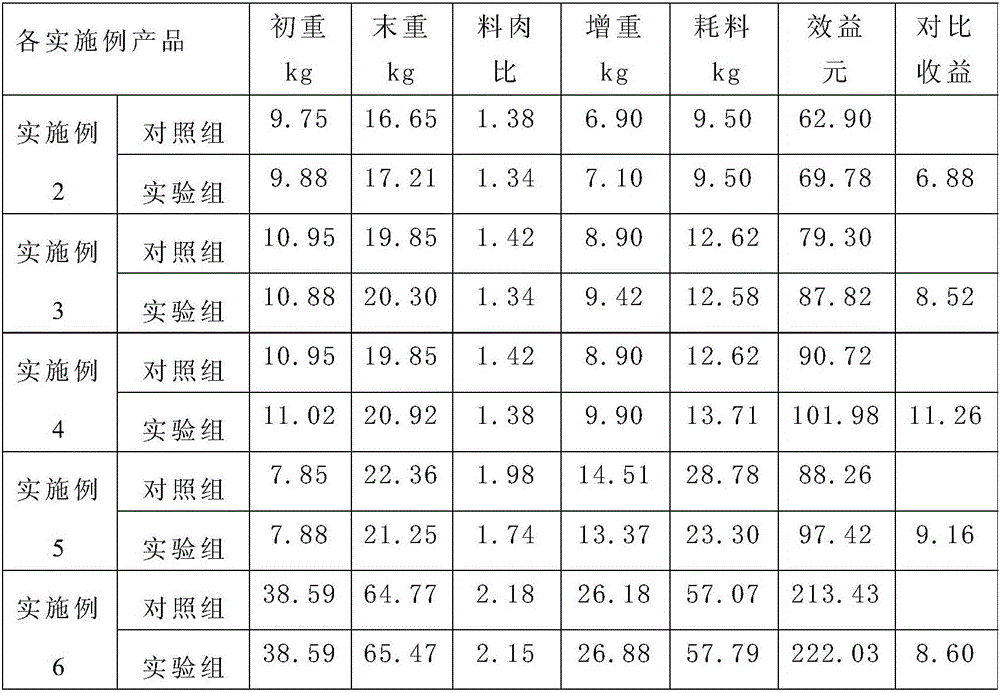

Embodiment 2

[0026] A kind of water-soluble plant essential oil feed additive, by weight percentage, its formula is:

[0027] Cinnamaldehyde 30%, thymol 6%, eugenol 7%, carvacrol 8%, emulsifier polyoxyethylene 20 sorbitan monooleate 3%, purified water 46%.

[0028] The preparation method of the water-soluble plant essential oil feed additive comprises the following steps:

[0029] 1) Mix cinnamaldehyde, thymol, eugenol, and carvacrol according to the above weight ratio, and fully stir to obtain a semi-finished plant essential oil;

[0030] 2) Mix the semi-finished plant essential oil with the emulsifier polyoxyethylene 20 sorbitan monooleate, and stir with a high-speed homogenizer. The speed of the high-speed homogenizer is 22000r / min, and the homogenization time is 6-6 8min to make it fully emulsified;

[0031] 3) Add the semi-finished product of emulsified plant essential oil into solvent water and stir well to obtain a finished product, and the weight percentage of plant essential oil...

Embodiment 3

[0033] A kind of water-soluble plant essential oil feed additive, by weight percentage, its formula is:

[0034] 20% cinnamaldehyde, 14% thymol, 5.5% eugenol, 13% carvacrol, 3% emulsifier, a mixture of propylene glycol and polyoxyethylene 20 sorbitan monooleate in a ratio of 3:1 by weight ; Purified water 44.5%.

[0035] The feed additive of this example is prepared according to the preparation method of Example 1 to obtain a finished product, and the weight percentage of plant essential oil in the finished product is 52.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com