Wallboard with built-in strength enhancement mechanism, and production equipment of wallboard

A wallboard and strength technology, which is applied in the direction of metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of increasing the weight and non-existence of wallboards, so as to improve its own strength, facilitate storage, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

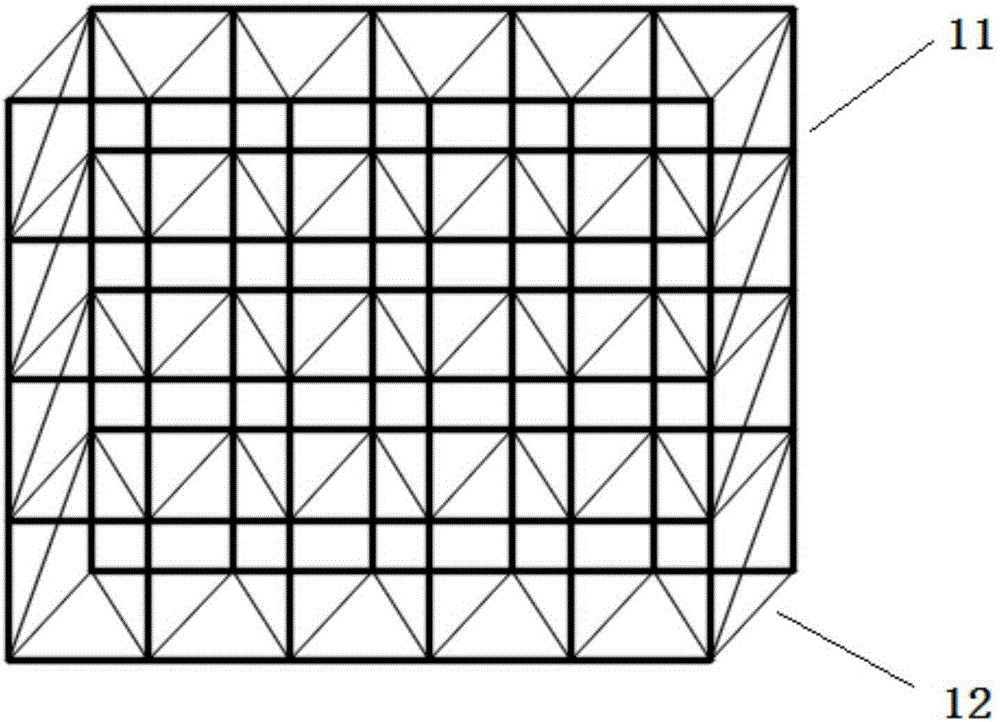

[0071] see figure 1 , a wallboard with a built-in strength enhancement mechanism, including a wallboard base body, a reinforcement mechanism is provided in the wallboard base body, the reinforcement mechanism includes at least two layers of mesh bodies 11 parallel to each other, and the adjacent ones of at least two layers of mesh bodies 11 The mesh body 11 is connected by metal connectors 12; the mesh body 11 includes at least two transverse reinforcements and at least two longitudinal reinforcements, the transverse reinforcements are fixedly connected to the longitudinal reinforcements, and the joints between the transverse reinforcements and the longitudinal reinforcements To connect the nodes of the metal connectors 12 , any node on one mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com