Tin concentrate separating system and process

A tin concentrate and process technology, applied in the field of non-ferrous metal beneficiation, can solve the problems of tin loss, heat not dissipated in time, economic loss, etc., and achieve the effects of reducing tin loss, simple structure, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

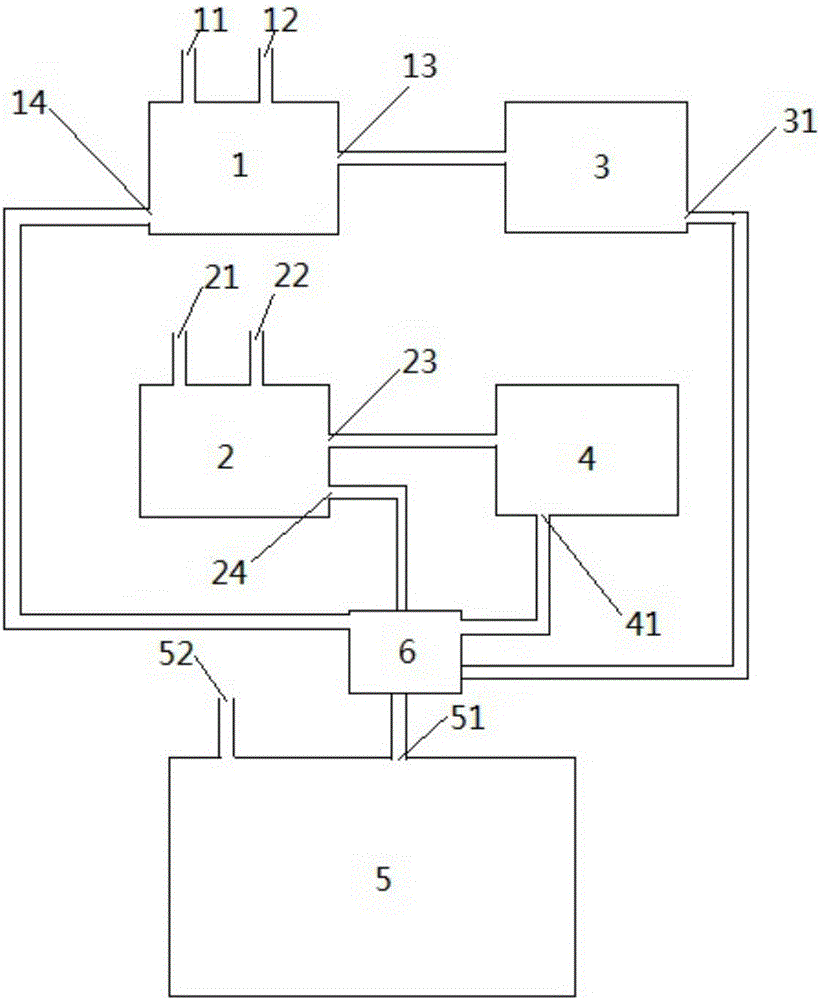

[0029] like figure 1 As shown, a tin concentrate mineral processing system includes a first flotation cell 1, a second flotation cell 2, a first rotary kiln 3, a second rotary kiln 4 and an electric furnace 5, and the electric furnace 5 is provided with a material mixture inlet 51, The material mixture inlet 51 is connected with the material mixing tank 6; the first flotation tank 1 is provided with the tin concentrate ore pulp inlet 11 and the No. 2 oil inlet 12 of styrene phosphonic acid, phenylpropanehydroxamic acid and foaming agent, the first flotation Pool 1 is also provided with a first flotation concentrate outlet 13 and a first flotation tailings outlet 14, both of which are respectively connected to the first rotary kiln 3 and the material mixing tank 6; the second flotation tank 2 is provided with a first flotation Tailings slurry inlet 21 and salicylic hydroxamic acid and foaming agent No. 2 oil inlet 22, the second flotation cell 2 is also provided with a second f...

Embodiment 2

[0045] like figure 1 As shown, a tin concentrate mineral processing system includes a first flotation cell 1, a second flotation cell 2, a first rotary kiln 3, a second rotary kiln 4 and an electric furnace 5, and the electric furnace 5 is provided with a material mixture inlet 51, The material mixture inlet 51 is connected with the material mixing tank 6; the first flotation tank 1 is provided with the tin concentrate ore pulp inlet 11 and the No. 2 oil inlet 12 of styrene phosphonic acid, phenylpropanehydroxamic acid and foaming agent, the first flotation Pool 1 is also provided with a first flotation concentrate outlet 13 and a first flotation tailings outlet 14, both of which are respectively connected to the first rotary kiln 3 and the material mixing tank 6; the second flotation tank 2 is provided with a first flotation Tailings slurry inlet 21 and salicylic hydroxamic acid and foaming agent No. 2 oil inlet 22, the second flotation cell 2 is also provided with a second f...

Embodiment 3

[0061] like figure 1 As shown, a tin concentrate mineral processing system includes a first flotation cell 1, a second flotation cell 2, a first rotary kiln 3, a second rotary kiln 4 and an electric furnace 5, and the electric furnace 5 is provided with a material mixture inlet 51, The material mixture inlet 51 is connected with the material mixing tank 6; the first flotation tank 1 is provided with the tin concentrate ore pulp inlet 11 and the No. 2 oil inlet 12 of styrene phosphonic acid, phenylpropanehydroxamic acid and foaming agent, the first flotation Pool 1 is also provided with a first flotation concentrate outlet 13 and a first flotation tailings outlet 14, both of which are respectively connected to the first rotary kiln 3 and the material mixing tank 6; the second flotation tank 2 is provided with a first flotation Tailings slurry inlet 21 and salicylic hydroxamic acid and foaming agent No. 2 oil inlet 22, the second flotation cell 2 is also provided with a second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com