A kind of synthetic method of sodium polydithiodipropane sulfonate

A technology of sodium polydithiodipropane sulfonate and synthesis method, which is applied in the field of two-step synthesis of sodium polydithiodipropane sulfonate for electroplating brightener, can solve the problem of difficulty in obtaining high-purity products, high production cost and long preparation time and other problems, to achieve the effects of stable yield, effective purity improvement, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

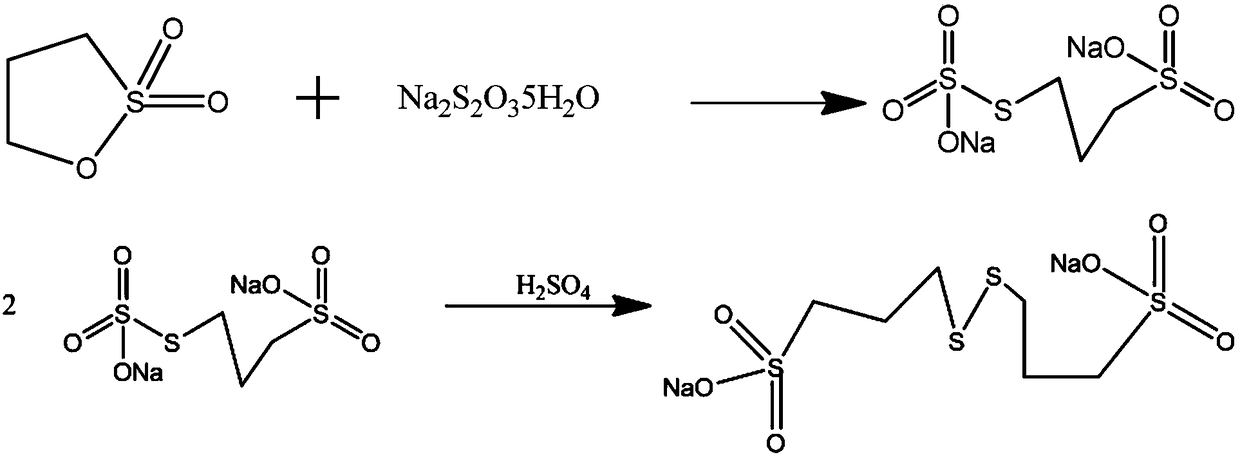

Method used

Image

Examples

Embodiment 1

[0018] Synthesis of Pent’s salt: Add 155g (0.625mol) sodium thiosulfate and 250ml water into a 1L four-necked bottle, stir until dissolved, cool down to 15°C, and slowly add 76.5g (0.625mol) sodium thiosulfate solution dropwise. mol) 300ml of ethanol solution of 1,3-propane sultone, and the dropping temperature is controlled not to exceed 30°C. After the dropwise addition was completed, the reaction was continued at 15° C. for 2 hours until a large amount of white solid appeared. Continue to stir at this temperature for 1 hour, then filter, wash the bottle with a little ethanol, and dry to obtain a white solid of Pent's salt with a yield of 97%. Wherein, the molar ratio of sodium thiosulfate, 1,3-propane sultone and total solvent participating in the reaction is 1:1:32.

[0019] Synthesis of SPS: Add 35g (0.125mol) of Pendt’s salt and 300ml of methanol into a 500ml reaction flask, stir and heat to reflux, then slowly add 35g of concentrated hydrochloric acid (0.35mol) dropwis...

Embodiment 2

[0021] Synthesis of Pent’s salt: Add 155g (0.625mol) sodium thiosulfate and 250ml water into a 1L four-necked bottle, stir until dissolved, cool down to 15°C, and slowly add 76.5g (0.625mol) sodium thiosulfate solution dropwise. mol) 300ml of methanol solution of 1,3-propane sultone, and the dropping temperature should not exceed 30°C. After the dropwise addition was completed, the reaction was continued at 0-15°C for 2 hours until a large amount of white solid appeared. Continue stirring at this temperature for 1 hour, then filter, wash the bottle with a little methanol, and dry to obtain a white solid of Pent's salt with a yield of 97%. Wherein, the molar ratio of sodium thiosulfate, 1,3-propane sultone and total solvent participating in the reaction is 1:1:37.

[0022] The synthesis of SPS: 35g (0.125mol) Pente salt and 200ml methanol are added in the 500ml reaction bottle, stir and heat to reflux, then slowly add 70g mass fraction is 50% sulfuric acid solution (0.7mol), d...

Embodiment 3

[0024] Synthesis of Pent’s salt: Add 155g (0.625mol) sodium thiosulfate and 125ml water into a 1L four-necked bottle, stir until dissolved, cool down to 15°C, slowly add 38.25g (0.625mol) sodium thiosulfate solution dropwise mol) 125ml of ethanol solution of 1,3-propane sultone, control the dropwise addition temperature not to exceed 30°C. After the dropwise addition was completed, the reaction was continued at 15° C. for 5 hours until a large amount of white solid appeared. Continue to stir at this temperature for 1 hour, then filter, wash the bottle with a little ethanol, and dry to obtain a white solid of Pent's salt with a yield of 97%. Wherein, the molar ratio of sodium thiosulfate, 1,3-propane sultone and total solvent participating in the reaction is 1:1:16.

[0025] The synthesis of SPS: 35g (0.125mol) Pente salt and 100ml methyl alcohol are joined in the 250ml reaction flask, stirring and heating to reflux, then slowly dripping 70g mass fraction is the concentrated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com