System and method for preparing cement co-production sulfur by utilizing urban wastes and industrial solid wastes

A technology for industrial solid waste and municipal waste, applied in chemical instruments and methods, chemical industry, sulfur preparation/purification, etc., can solve problems such as aggravating the environmental greenhouse effect, save heat, save water resources and energy, and achieve reduction quantified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

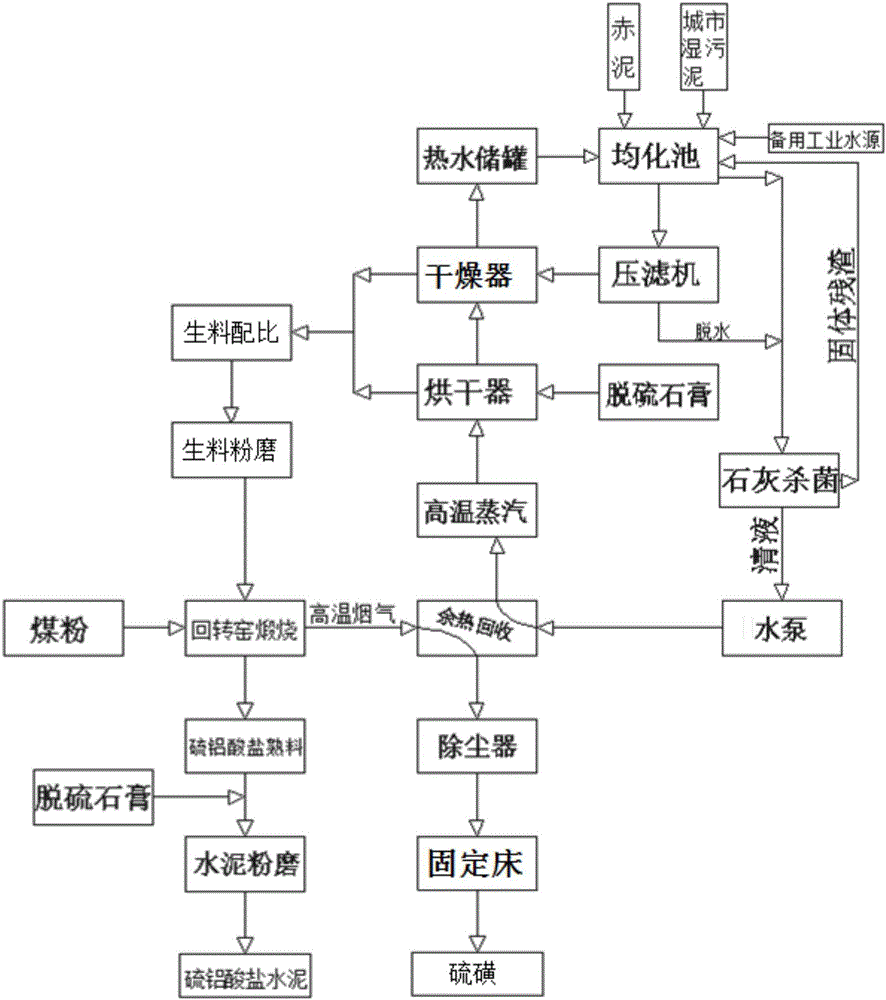

[0061] The present invention will be further described below in conjunction with accompanying drawing.

[0062] A system for producing cement co-production sulfur from municipal waste and industrial solid waste, including homogenization tank, filter press, dryer, raw meal grinding machine, rotary kiln, cement grinding machine, hot water storage tank, dust collector and reduction Fixed bed, red mud, wet sludge and industrial water enter the homogenization tank for homogenization treatment and dealkalization, and then enter the filter press for pressure filtration, and the solid materials after pressure filtration enter the dryer for drying, and after drying, they are combined with desulfurization gypsum Enter the raw material grinding unit for raw powder proportioning grinding, and the ground material enters the rotary kiln for high-temperature calcination to obtain sulphoaluminate clinker, and the sulphoaluminate clinker and desulfurized gypsum enter the cement grinding machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com