New dephosphorizing process for metal salt containing waste phosphoric acid

A technology of waste phosphoric acid and metal salts, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of phosphorus failing to meet environmental protection standards, polluting the environment, increasing treatment costs, etc. , to achieve the effect of stable processing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with specific embodiments.

[0015] Example :

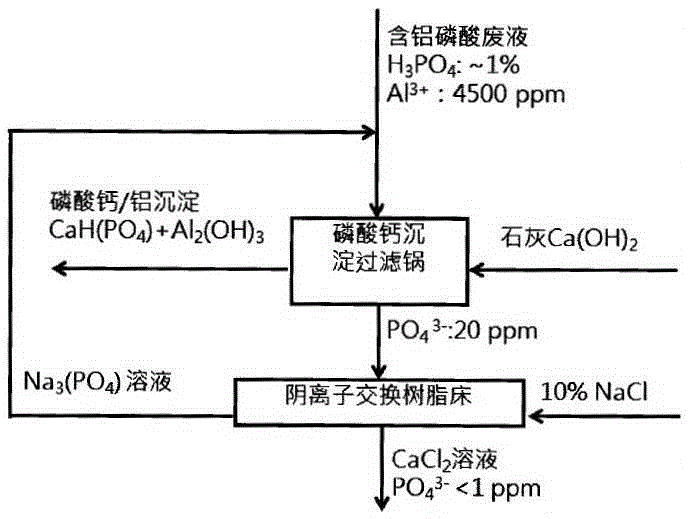

[0016] In this embodiment, aluminum-containing waste phosphoric acid with a phosphoric acid mass concentration of about 1% and an aluminum ion mass concentration of 4500 ppm is used as the waste liquid to be treated, and the process of the present invention is used to dephosphorize the waste liquid, see figure 1 , The specific process is as follows:

[0017] (1) Lime neutralization and preliminary filtration: adding lime to the aluminum-containing waste phosphoric acid solution, reacting to produce calcium phosphate precipitation that is slightly soluble in water, and then filtering, the filter residue is a mixed precipitation of calcium phosphate and aluminum hydroxide, and the filtrate is containing Sewage solution of trace calcium phosphate. The filter residue can be recycled as phosphate fertilizer, and the filtrate is sent to the next step for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com