Substrate processing apparatus, substrate processing method and recording medium

A substrate processing apparatus and technology for a substrate processing method are applied in the directions of chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

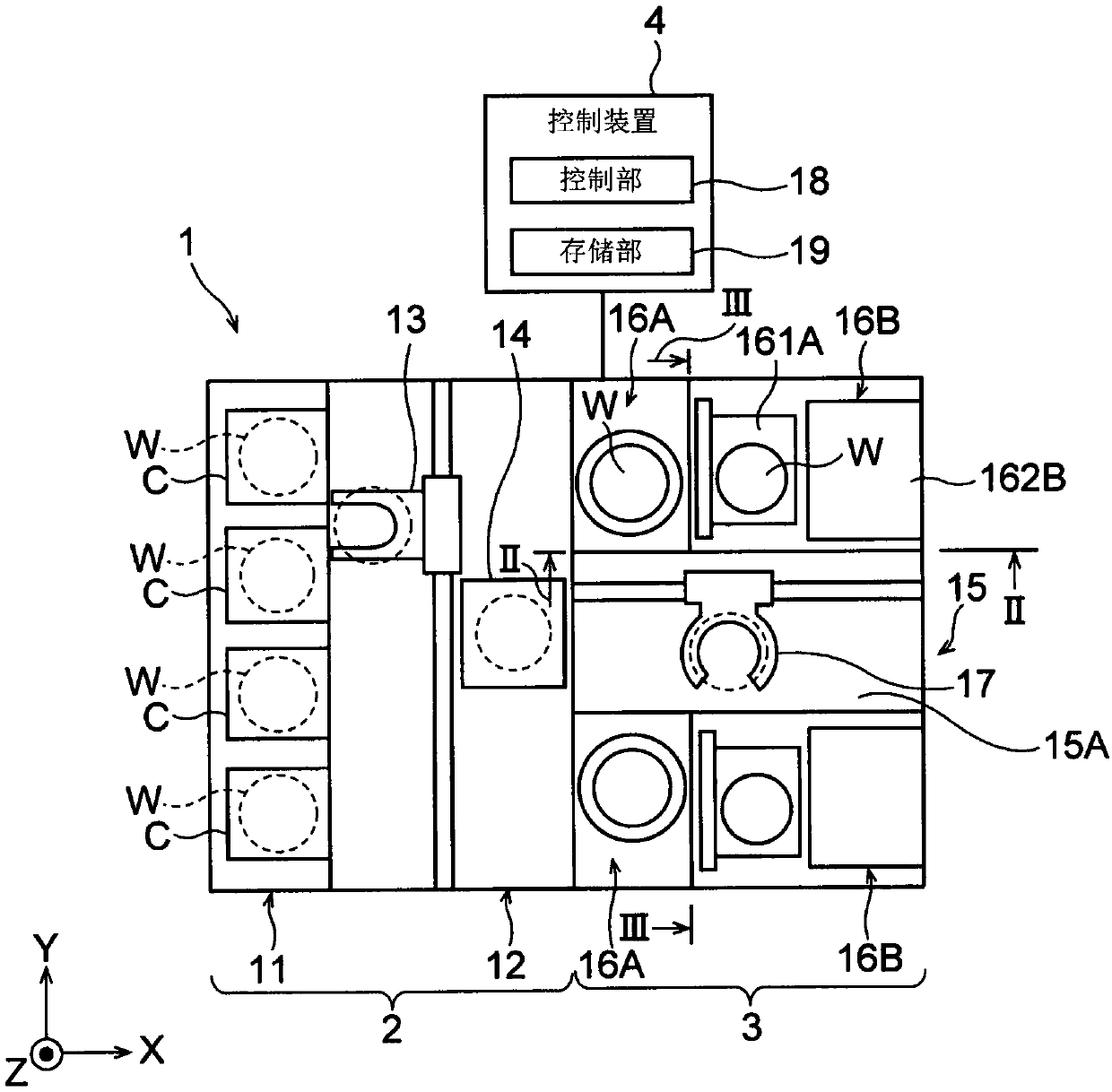

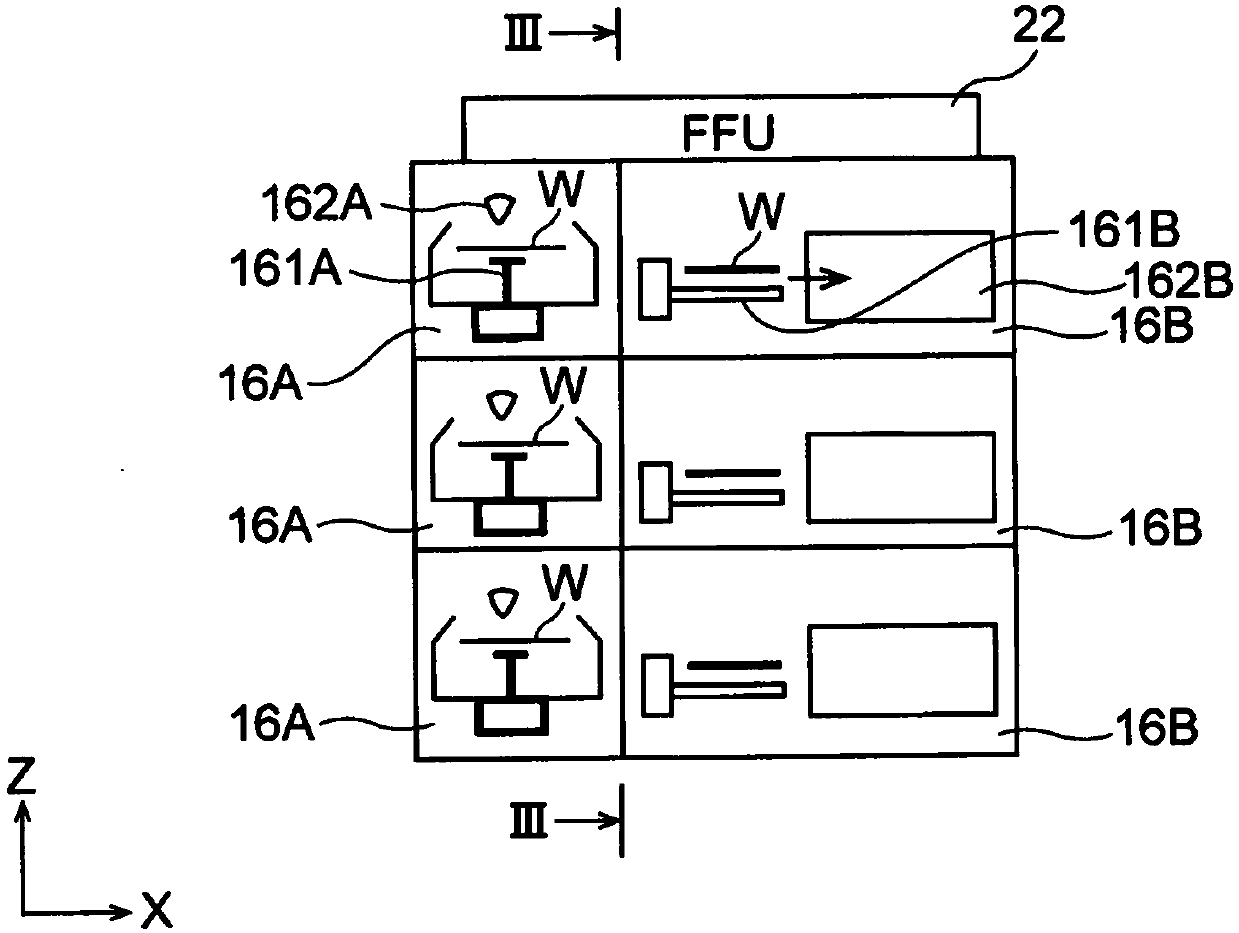

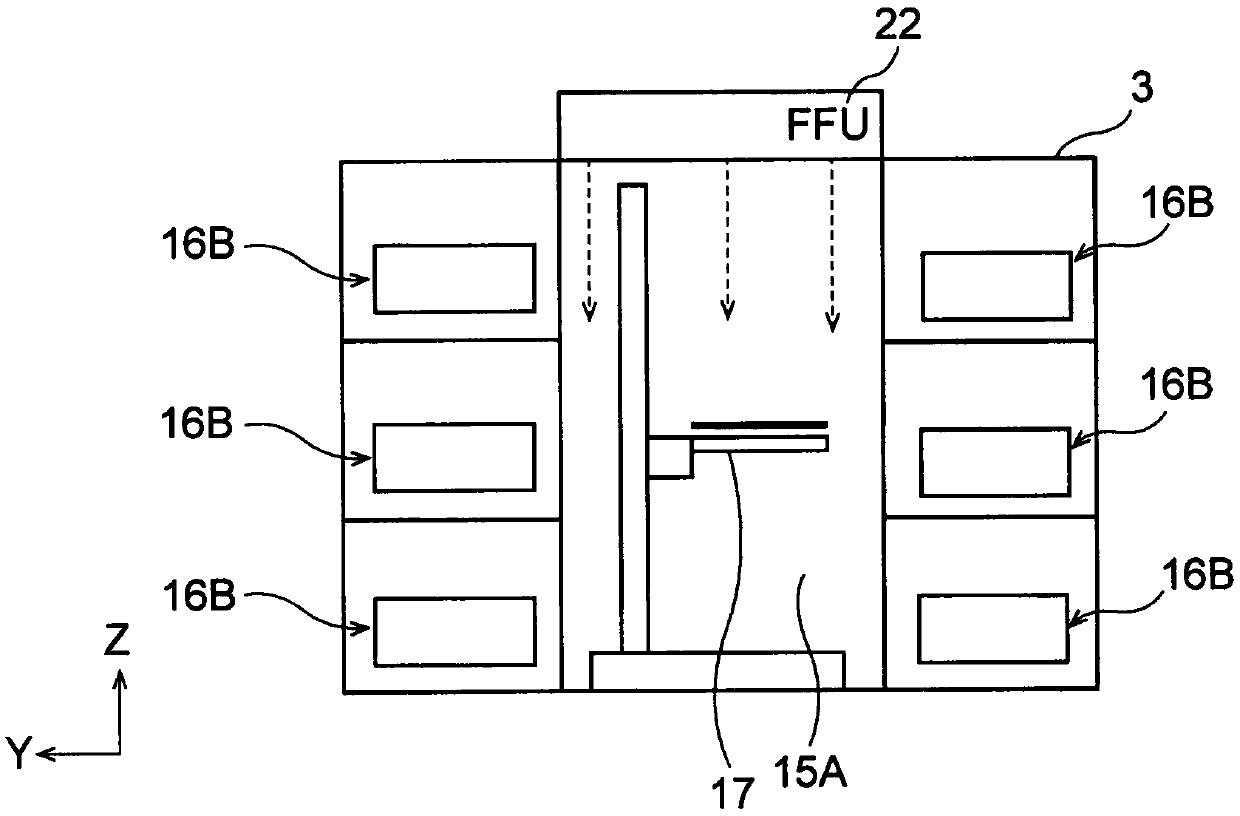

[0024] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0025] figure 1 It is a figure which shows the schematic structure of the board|substrate processing system which concerns on this embodiment. In the following, in order to clarify the positional relationship, the X axis, the Y axis, and the Z axis which are orthogonal to each other are defined, and the positive direction of the Z axis is the vertical upward direction.

[0026] like figure 1 As shown, the substrate processing system 1 includes a carry-in and carry-out station 2 and a processing station 3 . The carry-in and carry-out station 2 is provided adjacent to the processing station 3 .

[0027] The carry-in and carry-out station 2 includes a carrier placing part 11 and a conveying part 12 . A plurality of carriers C for accommodating a plurality of substrates, in this embodiment, semiconductor wafers (hereinafter referred to as wafers W) in a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com