Flue gas desulfurization, denitration and dust removal device and method

A technology for desulfurization, denitrification, and dust removal devices, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as inability to remove catalysts, inability to process adjustments, and reduce the effect of flue gas dust removal, so as to facilitate large-scale promotion. Application, simple operation, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

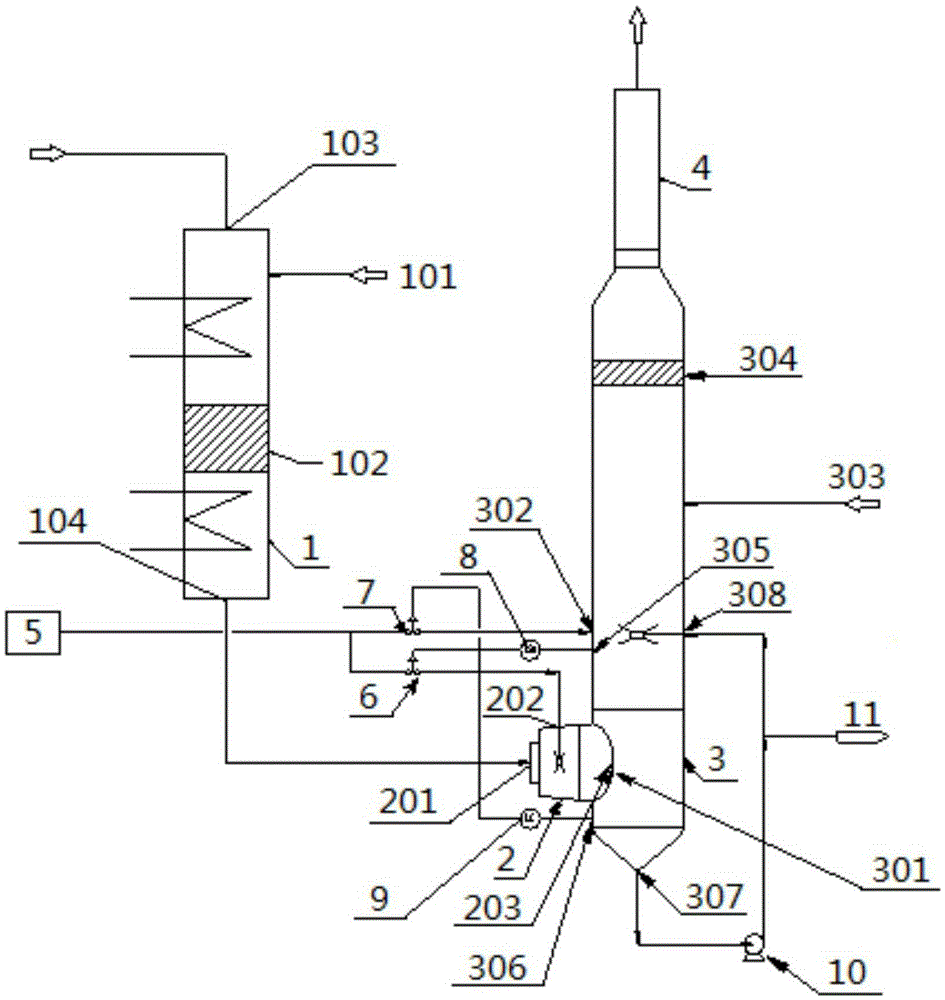

[0071] This embodiment provides a flue gas desulfurization, denitrification and dust removal device, which includes: a waste heat boiler 1 , a cooler 2 , a washing tower 3 , a chimney 4 , a water inlet 5 , a temperature control valve 6 , and a liquid level control valve 7 .

[0072] The upper part of the waste heat boiler 1 is provided with an ammonia gas inlet 101, the middle part is provided with a denitrification reactor 102, the top is provided with a first flue gas inlet 103, and the bottom part is provided with a flue gas outlet 104; the denitrification catalyst loaded in the denitrification reactor 102 is Topsoe's DNX series Catalyst, BASF O4-85 catalyst, FN-2 catalyst of Fuyan Research Institute.

[0073] The lower part of the washing tower 3 is provided with a second flue gas inlet 301, a water inlet 302, and a liquid level detection port 306. The middle part is provided with a lye inlet 303 and a temperature detection port 305. The upper part is provided with a deliqu...

Embodiment 2

[0079] In this embodiment, the device provided in Embodiment 1 is used for desulfurization, denitrification and dust removal treatment, which specifically includes the following steps:

[0080] The flue gas is introduced into the waste heat boiler 1, and when the temperature in the waste heat boiler 1 is between 340-380°C, the ammonia gas with an ammonia volume concentration of 3-5% is passed into the waste heat boiler 1 to mix the flue gas with the ammonia gas, Then, the flue gas is denitrated by the denitrification reactor 102 in the waste heat boiler 1 to obtain denitrification flue gas.

[0081] Make the denitrification flue gas enter the cooler 2, enter the washing tower 3 after cooling, and add NaOH solution with a mass concentration of 10% to the washing tower 3 at the same time, and carry out desulfurization and dust removal treatment on the denitrification flue gas through the NaOH solution. The level control valve keeps the liquid level in the washing tower 3 stable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com