Method for repairing copper film sample fatigue damage by multiple vibration treatment

A technology of fatigue damage and multiple vibrations, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of poor repair effect and achieve remarkable results, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

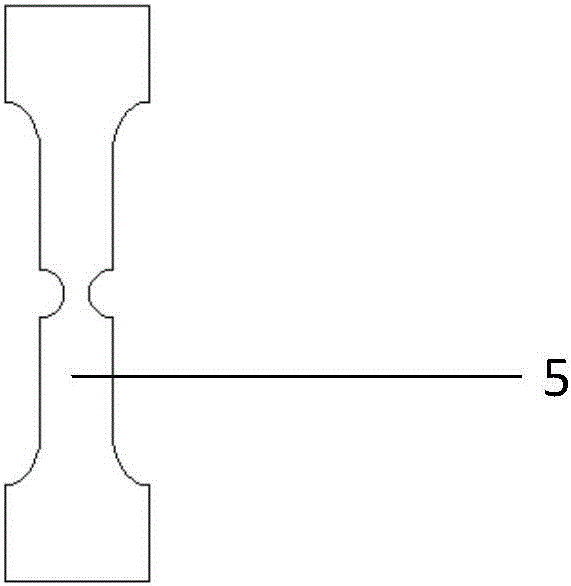

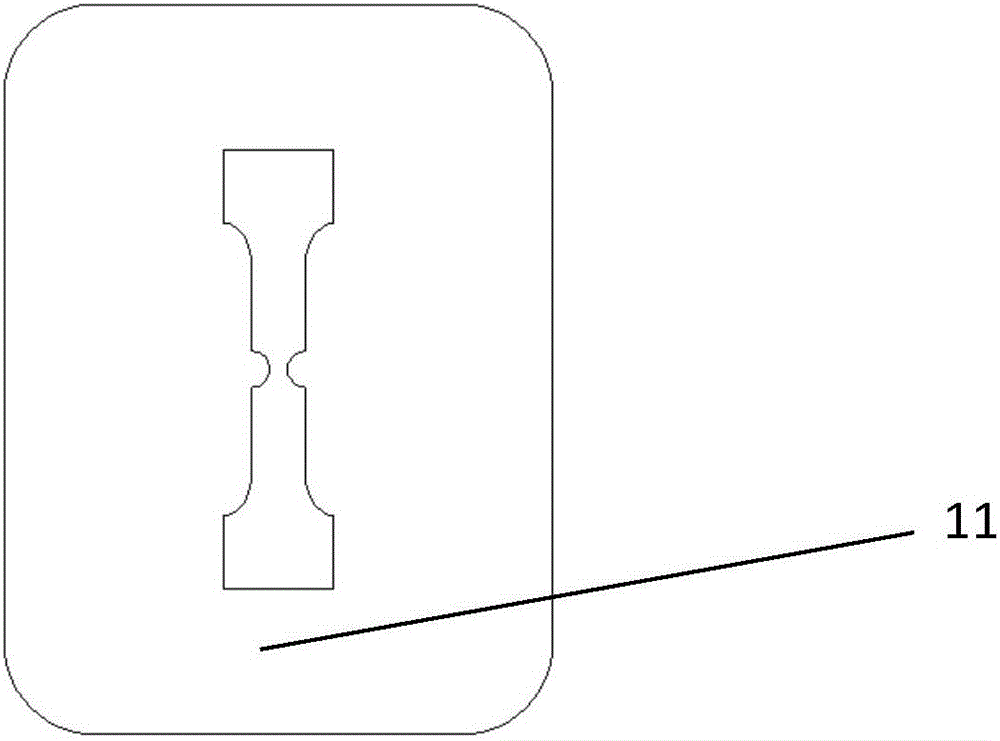

[0027] Below in conjunction with accompanying drawing, the method of the present invention is further elaborated by giving an example, please refer to Figure 1 to Figure 4 . A pulsating cyclic load with a maximum stress of 180 MPa is applied to the specimen, and the cyclic loading time is 0.5 times the original life of the specimen, and then it is subjected to multiple vibration repairs until the specimen breaks. A method for repairing copper thin film fatigue damage by multiple vibration treatment, the steps are:

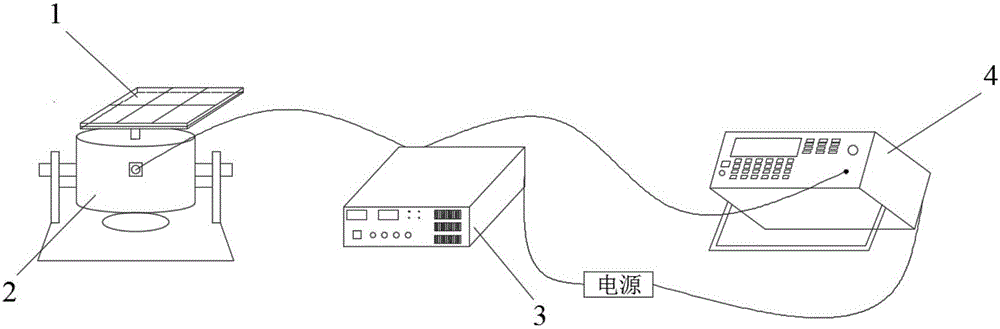

[0028] Step 1) provide a vibration treatment repair device, the vibration treatment repair device includes a test piece isolation device 1, a mode exciter 2, a power amplifier 3 and a waveform generator 4; the test piece isolation device 1 and the mode excitation The vibrating table of the device 2 is rigidly fixed together; the modal exciter 2 is connected to the power amplifier 3; the waveform generator 4 is connected to the power amplifier 3, and both are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com