Continuous sampling and analyzing device used for loading/unloading LNG (liquefied natural gas) and using method

A sampling analysis and gasification device technology, which is applied in the field of liquefied natural gas sampling and analysis, can solve the problems of early gasification of LNG samples, unadjustable, insufficient heater power, etc., achieves stable and continuous sampling, maintains representativeness, and occupies space small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention. In the description of the present invention, it should be understood that the terms "first", "second" and so on are only used for the purpose of description, and cannot be interpreted as indicating or implying relative importance. It should be noted that each of the present invention The connections between devices are all connected by pipelines.

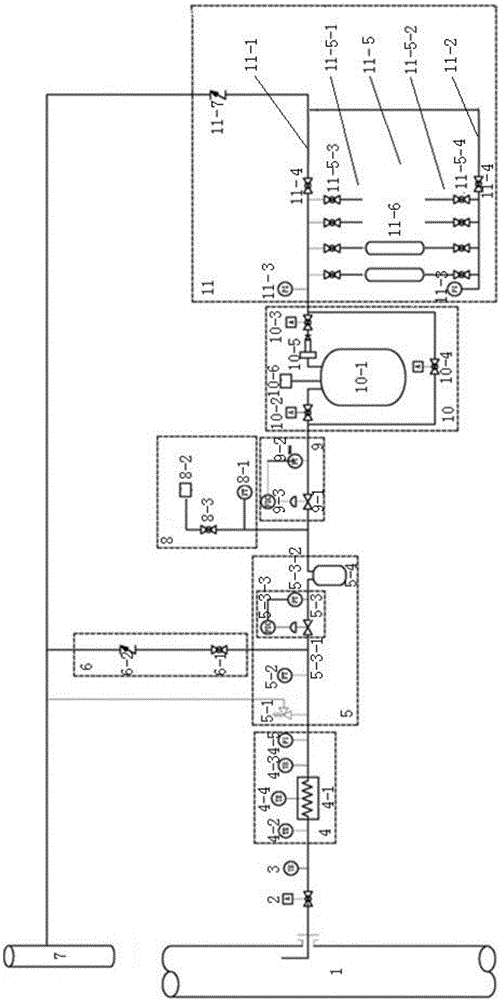

[0019] Such as figure 1 As shown, the sampling analysis device for LNG loading and unloading of the present invention includes an LNG sampling probe 1, an isolation shut-off valve 2, a temperature detection element 3, a gasification device 4, a sampling main pipeline 5, a BOG return device 6, a BOG main pipe 7, and an online a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com