Preparation method of chitosan gel series material

A technology of chitosan and gel, which is applied in the field of preparation of chitosan gel-based materials, can solve the problems of high energy consumption and uneconomical, and achieve low cost, environmental protection and operator health, and excellent product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

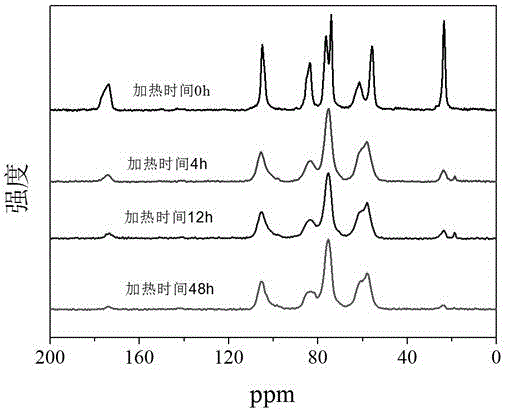

Method used

Image

Examples

Embodiment 1

[0028] The commercially available chitin was soaked in 4wt% NaOH aqueous solution for 48h, filtered and washed with 1wt% HCl aqueous solution for 6h, filtered and washed with water, and freeze-dried to obtain chitin powder with a degree of acetylation of 93%. The mixed solvent of 20g potassium hydroxide, 4g urea and 81g water is pre-cooled to -20°C, 1g of chitin is added, and the mixture is pre-cooled to -20°C for 12h. Thaw at room temperature to obtain a transparent chitin solution, put it in a blast oven set at 60 ℃, and heat for 2 hours to gel and deacetylate. Place the deacetylated chitosan gel in a 75% ethanol aqueous solution for 72 hours and wash with water to obtain a physically cross-linked chitosan hydrogel. The measured tensile strength is 0.3MPa, the breaking strain is 110%, and the water content is 92wt. %, the degree of deacetylation is 51%.

Embodiment 2

[0030] The commercially available chitin was soaked in 4wt% NaOH aqueous solution for 48h, filtered and washed with 1wt% HCl aqueous solution for 6h, filtered and washed with water, and freeze-dried to obtain chitin powder with a degree of acetylation of 93%. A mixed solvent of 20g potassium hydroxide, 4g urea, and 81g water is pre-cooled to -20°C, 1g of chitin is added, and the mixture is pre-cooled to -20°C and kept for 12 hours. Thaw at room temperature to obtain a transparent chitin solution, put it in a blast oven set at a temperature of 40 ℃, and heat for 12 hours to gel and deacetylate. The deacetylated chitosan gel was placed in deionized water for 72 hours and washed with water to obtain a physically crosslinked chitosan hydrogel. The measured compressive strength was 1.3MPa, the breaking strain was 83%, and the moisture content was 97wt%. The degree of acetylation is 58%.

Embodiment 3

[0032] The commercially available chitin was soaked in 4wt% NaOH aqueous solution for 48h, filtered and washed with 1wt% HCl aqueous solution for 6h, filtered and washed with water, and freeze-dried to obtain chitin powder with a degree of acetylation of 93%. The mixed solvent of 20g potassium hydroxide, 4g urea and 81g water is pre-cooled to -20°C, 1g of chitin is added, and the mixture is pre-cooled to -20°C for 12h. Thaw at room temperature to obtain a transparent chitin solution, put it in a blast oven set at a temperature of 50 ℃, and heat for 12 hours to gel and deacetylate. The deacetylated chitosan gel was placed in deionized water for 72 hours and washed with water to obtain a physically crosslinked chitosan hydrogel. The measured compressive strength was 1.3MPa, the breaking strain was 79%, and the moisture content was 96wt%. The degree of acetylation is 62%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com