Electric heating aluminum pipe assembling carrier

An aluminum tube and carrier technology, which is applied in the field of electric heating aluminum tube assembly carriers, can solve the problems of slow assembly speed and single effect of carrying devices, and achieves the effect of high automation characteristics and improved assembly speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

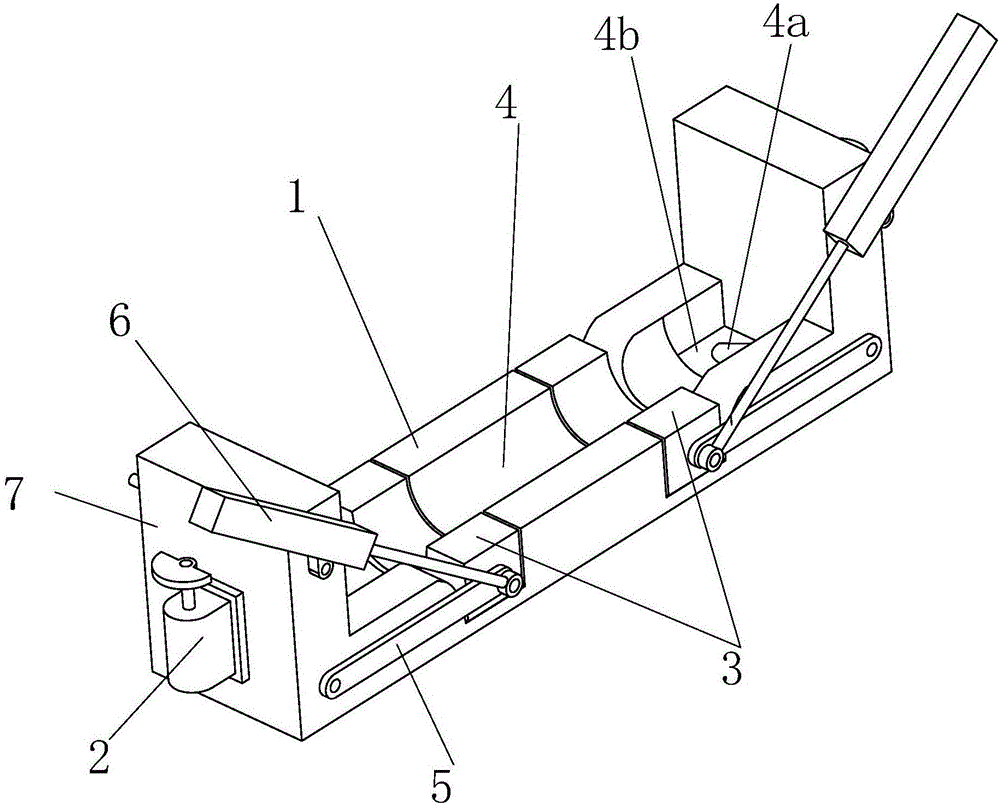

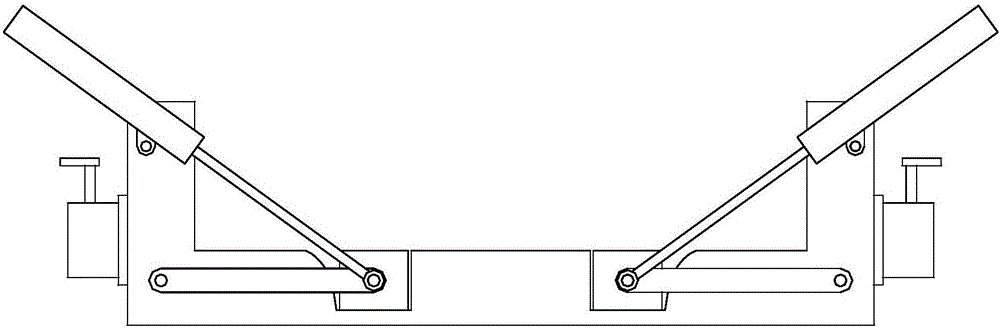

[0013] Such as Figure 1 to Figure 2 As shown, an electric heating aluminum tube assembling carrier includes a carrying frame 1. The carrying frame 1 is provided with side walls 7 at the front and rear ends, and a vibration motor 2 is installed on the side walls 7. The upper middle part of the frame 1 is close to the front side and the middle part is close to the rear side are both supported with a lifting plate frame 3, the carrying frame 1 and the two lifting plate frames 3 are both penetrated in the front and rear direction with arc-shaped grooves 4, the arc-shaped grooves 4 The front and rear sides of the two flat grooves 4b are provided with flat grooves 4b, the flat groove 4b located on the rear side of the two flat grooves 4b is provided with an escape through hole 4a, the lower right en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com