A kind of preparation method of composite sand core for metal mold casting

A metal mold casting and composite sand core technology, which is applied in casting molding equipment, metal processing equipment, mold cores, etc., can solve the problems of high temperature of the core head, which is difficult to metal mold, and achieve good initial strength, excellent yield and collapse, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

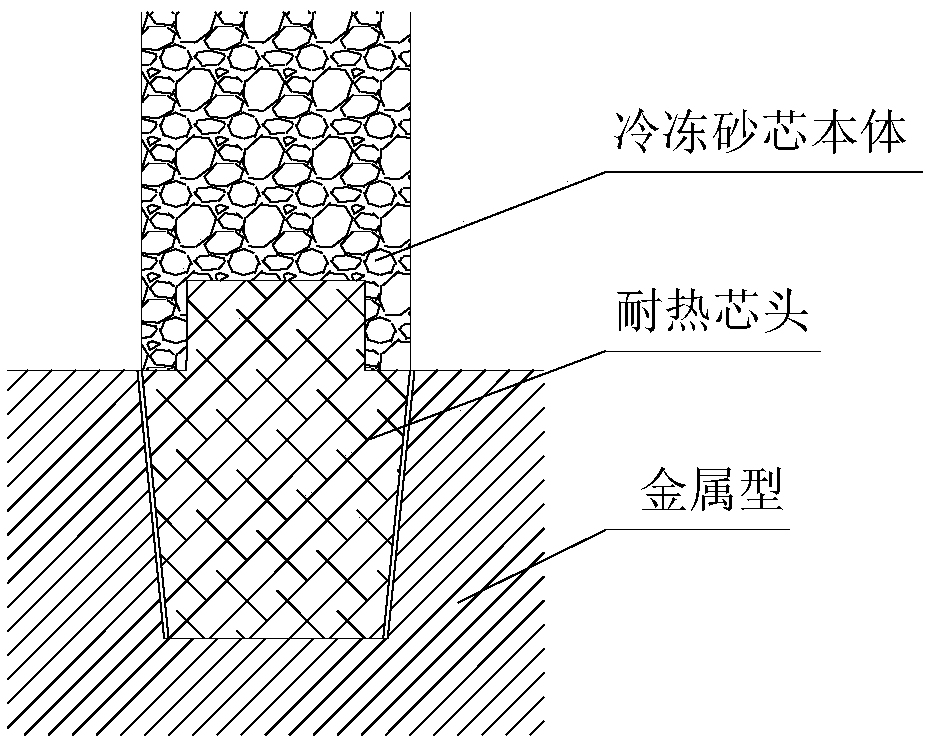

[0025] A method for preparing a composite sand core for metal mold casting, the composite sand core includes a heat-resistant core head and a sand core body, comprising the following preparation steps:

[0026] A The ceramic core head is made of ceramic materials with excellent heat resistance and good heat insulation ability. The shape and size of the matching part of the ceramic core head and the metal core seat are determined according to the casting process drawing. The shape and size of the matching part of the ceramic core head and the sand core body are: the minimum value of the transverse equivalent diameter is 2mm, and the maximum value of the equivalent diameter is 99%~1% of the external dimension of the sand core body in this direction; the minimum value of the longitudinal length is 2mm, The maximum longitudinal length is 99%~1% of the maximum size of the sand core body in this direction. The internal porosity and void penetration rate of the ceramic core head are...

Embodiment 2

[0033] The composite sand core includes a heat-resistant core head and a sand core body, including the following preparation steps:

[0034] A Use heat-resistant sand blocks to prepare heat-resistant sand block cores. The shape and size of the matching part of the heat-resistant sand block core head and the metal core seat are determined according to the casting process drawing. The shape and size of the matching part of the heat-resistant sand block core head and the sand core body are: the minimum equivalent diameter in the transverse direction is 2mm, and the maximum equivalent diameter is 99%~1% of the external dimension of the sand core body in this direction; the minimum longitudinal length The maximum length of the longitudinal length is 99%~1% of the maximum size of the sand core body in this direction. The internal porosity and void penetration rate of the heat-resistant sand block core head are adjusted according to the air permeability requirements of the sand core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com