Process for fabricating vertically-assigned gallium arsenide semiconductor nanowire array of large area

A nanowire array, manufacturing method technology, applied in semiconductor/solid-state device manufacturing, nanostructure manufacturing, semiconductor device and other directions, can solve the problem of difficult to manufacture high aspect ratio nanowires, difficult to manufacture with uniform diameter and length. problems with nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

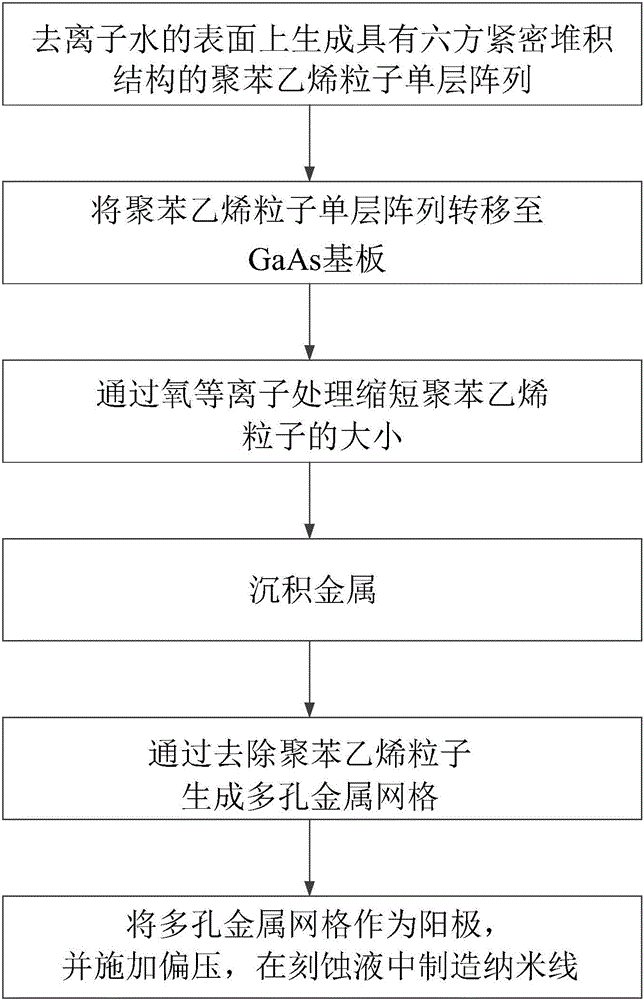

[0101] 【Example 1】 Figure 9 A method for the generation of vertical nanowires.

[0102] Pretreatment of GaAs substrate

[0103] The gallium arsenide n-type (100) substrate, n-type (111) substrate and p-type (100) substrate of iNexus Company were cleaned and dried with acetone, ethanol and deionized water in order to remove the contamination existing on the substrate surface objects, and then use oxygen plasma (oxygen: 100sccm, plasma power: 300W, time: 20 minutes) to increase the surface humidity.

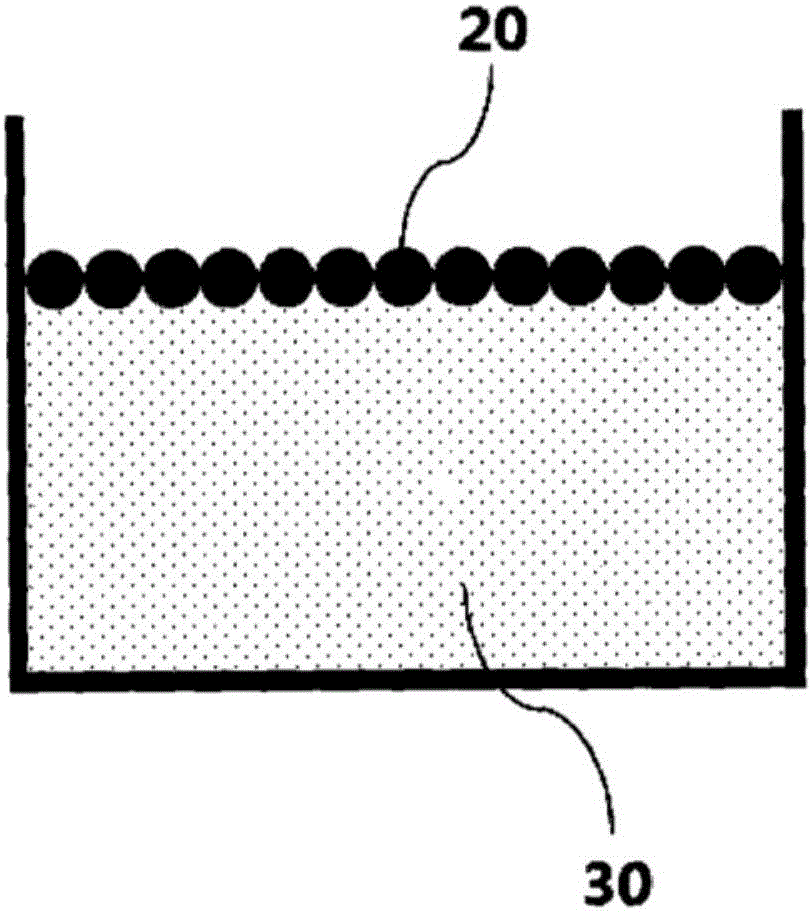

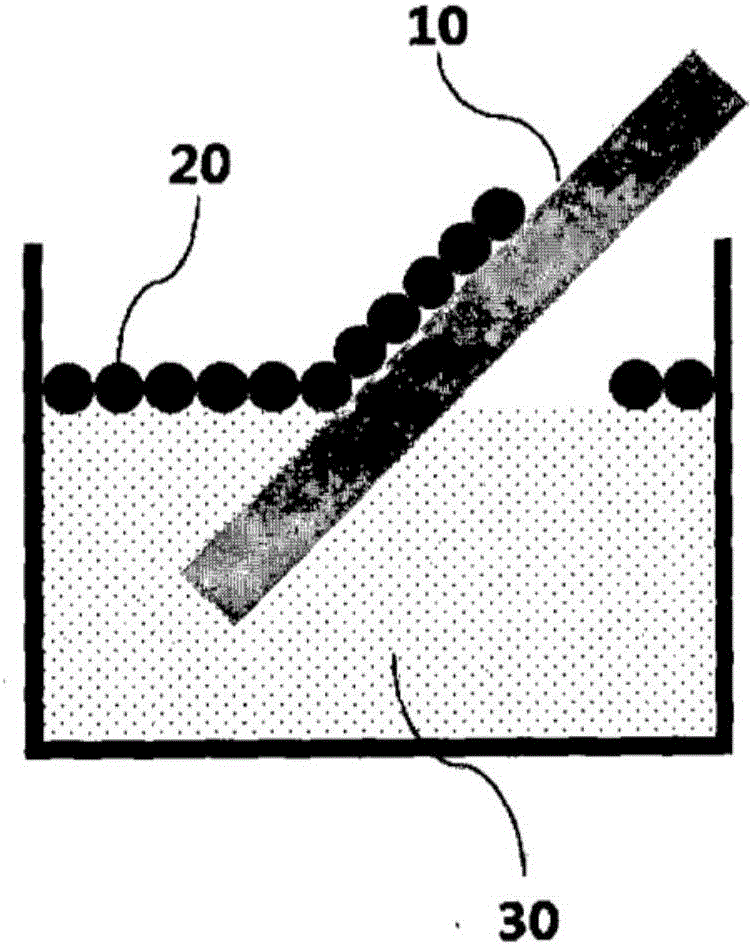

[0104] Fabrication of Monolayer Arrays of Polystyrene Nanoparticles

[0105] The polystyrene nanoparticles (average particle diameter 250nm) of Microparticles company and propanol (C 3 h 7 OH) after mixing, use a syringe pump to inject on the surface of the deionized water contained in the beaker, so that the monolayer array of polystyrene nanoparticles with a hexagonal close-packed structure is uniformly formed on the surface of the deionized water, and then After the pretre...

Embodiment 2

[0110] [Example 2] Figure 10 The method for the generation of vertical nanowires

[0111] Except that the n-type (100) GaAs substrate in the first embodiment is changed to an n-type (111) GaAs substrate, the others are the same as the above-mentioned first embodiment.

Embodiment 3

[0112] [Example 3] Figure 11 The method for the generation of vertical nanowires

[0113] Except that the n-type (100) GaAs substrate in the embodiment 1 is changed to a p-type (100) GaAs substrate, the others are the same as the above-mentioned embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com