Direct insertion type box structure of control board on top of aircraft cockpit

A box structure, cockpit technology, applied to the circuit layout, component plug-in combination, coupling device and other directions on the support structure, can solve the problems of complex manufacturing, inconvenient maintenance, time-consuming cable laying, etc. The effect of reducing the number of parts required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

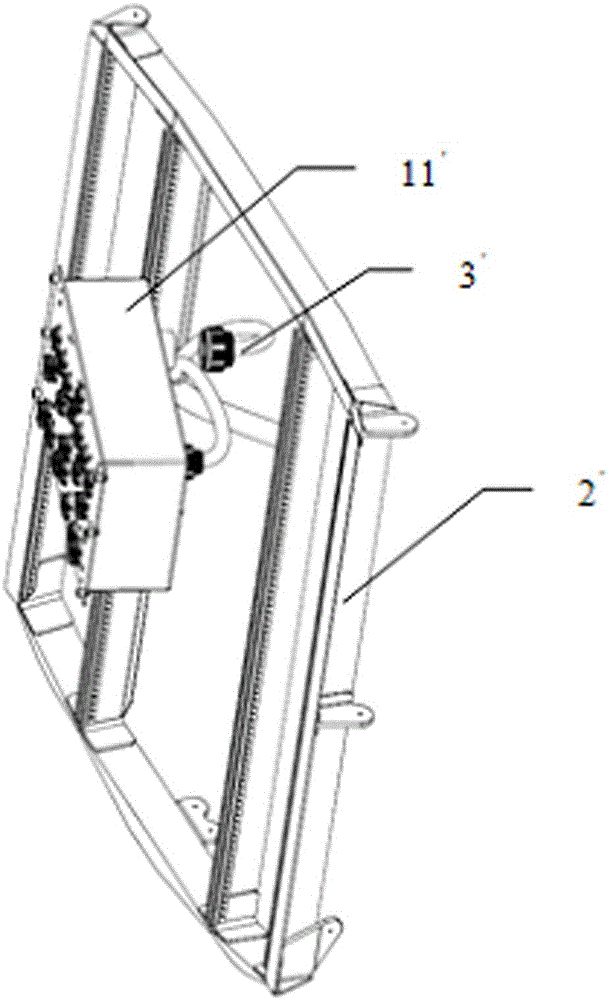

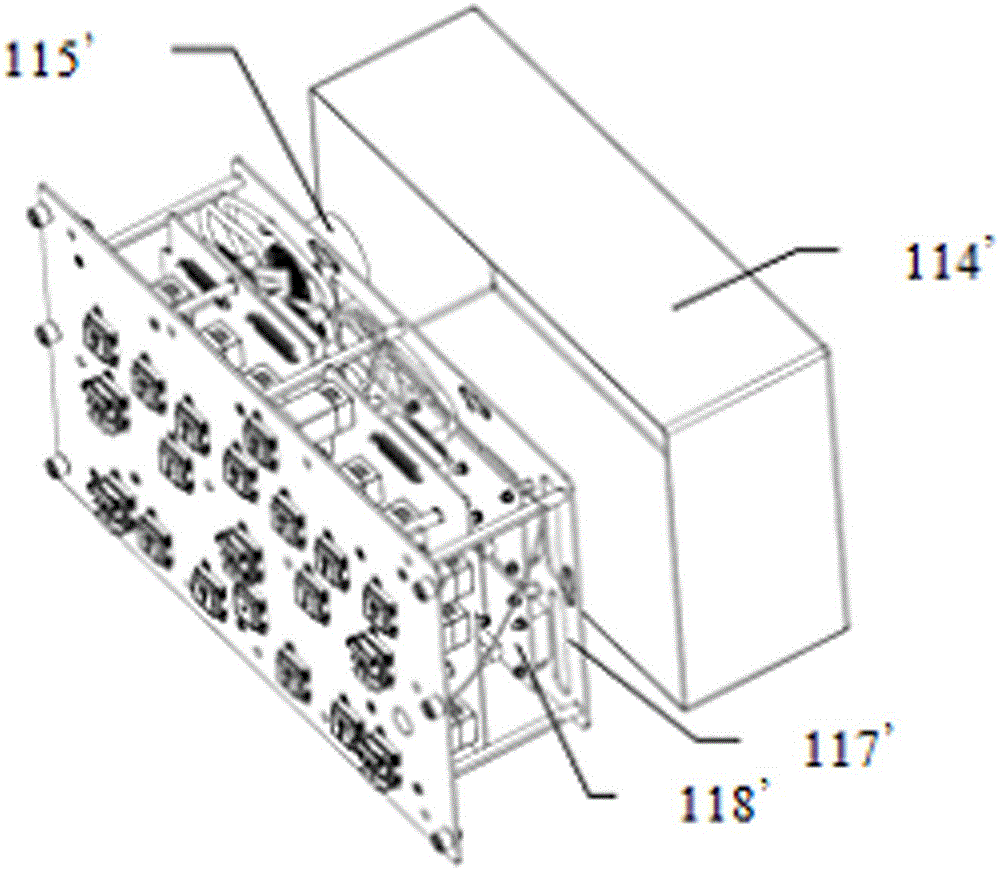

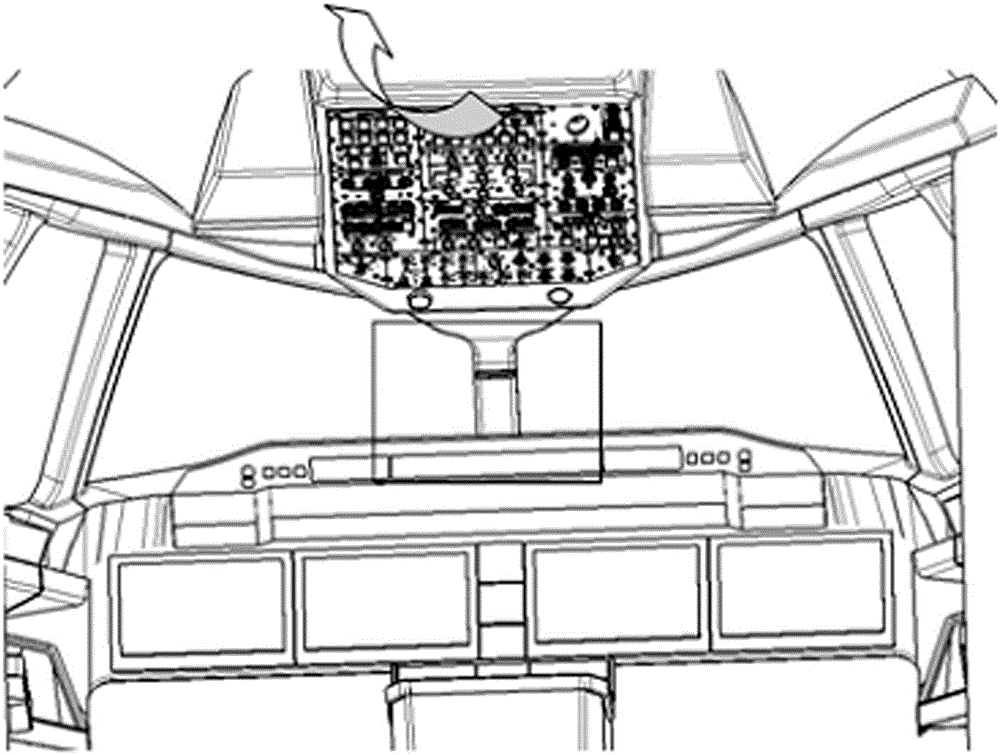

[0045] refer to Figure 3-8 ,in, image 3 It is an installation schematic diagram of an embodiment of the in-line box structure of the top control panel of the aircraft cockpit according to the present invention; Figure 4 It is a structural schematic diagram of an embodiment of the in-line box structure of the top control panel of the aircraft cockpit according to the present invention; Figure 5 It is a specific structural schematic diagram of an embodiment of the in-line box structure of the top control board of the aircraft cockpit according to the present invention; Image 6 It is a partial structural diagram of a certain control panel in an embodiment of the in-line box structure of the top control panel of the aircraft cockpit according to the present invention; Figure 7It is a structural schematic diagram of the guide structure in an embodiment of the in-line box structure of the top control panel of the aircraft cockpit according to the present invention; Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com