Automatically ignited microwave plasma torch device

A microwave plasma, automatic ignition technology, applied in the plasma torch technology and the fields of chemistry and measurement, can solve the problems of increasing the complexity of the system, potential safety hazards, and impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

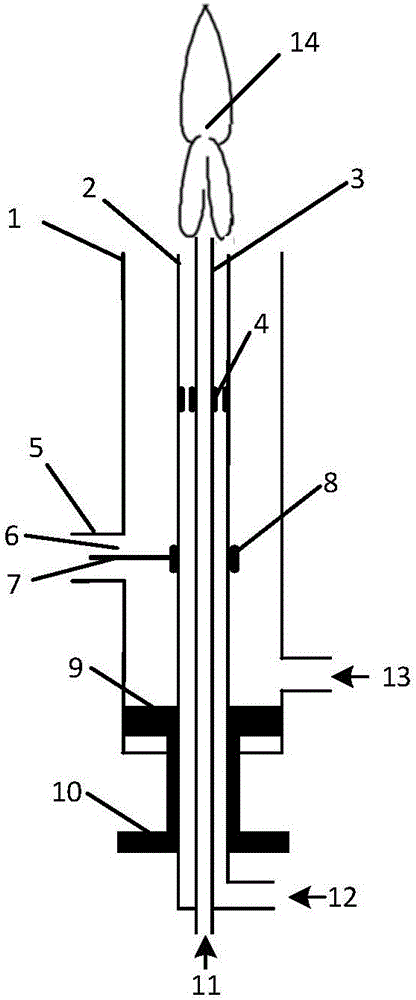

[0023] see figure 1 , a microwave plasma torch device with automatic ignition, consisting of an outer tube (1), a middle tube (2), an inner tube (3), a spacer (4), a microwave coupling interface (5), and an outer tube microwave opening (6 ), a coupling rod (7), a coupling ring (8), a reflective end face (9), and an adjustment piston (10), the outer tube (1), the middle tube (2), and the inner tube (3) have three metal tubes Shaft structure, between the middle tube (2) and the inner tube (3), there is a metal spacer (4) to ensure coaxiality and adjust the electromagnetic field distribution, and the coupling ring (8) is set on the outer wall of the middle tube (2), microwave coupling The interface (5) is arranged on the outer tube (1) to form the outer tube microwave opening (6), the coupling rod (7) is fixed on the coupling ring (8), and is located between the outer tube microwave openings (6), and the outer tube (1) There is a reflective end face (9) between it and the middle...

Embodiment 2

[0034] see figure 1 A microwave plasma torch device with automatic ignition, the automatic ignition of the microwave plasma torch requires the formation of a local strong electric field in the plasma formation area at the open end to form an electric breakdown, and this strong electric field can be adjusted by adjusting the middle tube (2) and the inner tube (3) Relative position realization. In order to ensure the normal operation of the torch, it is necessary to be equipped with a microwave source that matches the design of the torch, such as a 200W continuous wave output 2.45GHz microwave source.

[0035] The inner diameter of the outer tube (1) is preferably 20 mm, the outer diameter of the middle tube (2) is preferably 7 mm, and the inner diameter of the inner tube (3) is preferably 2 mm. The wall thickness of the middle pipe (2) is 1mm, and the wall thickness of the inner pipe (3) is 0.5mm.

[0036] Described torch tube working gas selects Ar gas, and working gas (12) ...

Embodiment 3

[0045] see figure 2 , is a schematic diagram of an automatic ignition microwave plasma torch atomic emission spectrometer device.

[0046] The core part of the microwave plasma torch atomic emission spectrometer is the microwave source (16) and the torch tube (17). The microwave source (16) provides the microwave energy to maintain the continuous operation of the plasma. The microwave frequency for civil use is more 915±50MHz And 2450±50MHz, within the power range of about kilowatts required by the plasma microwave source, a continuous wave high-power magnetron of 2450±50MHz is generally selected. The core part of the microwave source (16) is the magnetron, and the power supply (15) supplies power to the magnetron, and the closed circuit protection device (20) monitors according to the state of the microwave source (16) to prevent the magnetron from being too large. If the temperature of the microwave source is too high, if an abnormal situation occurs, the microwave output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com