Compound movement winding machine for large-and-middle-scale motor coil

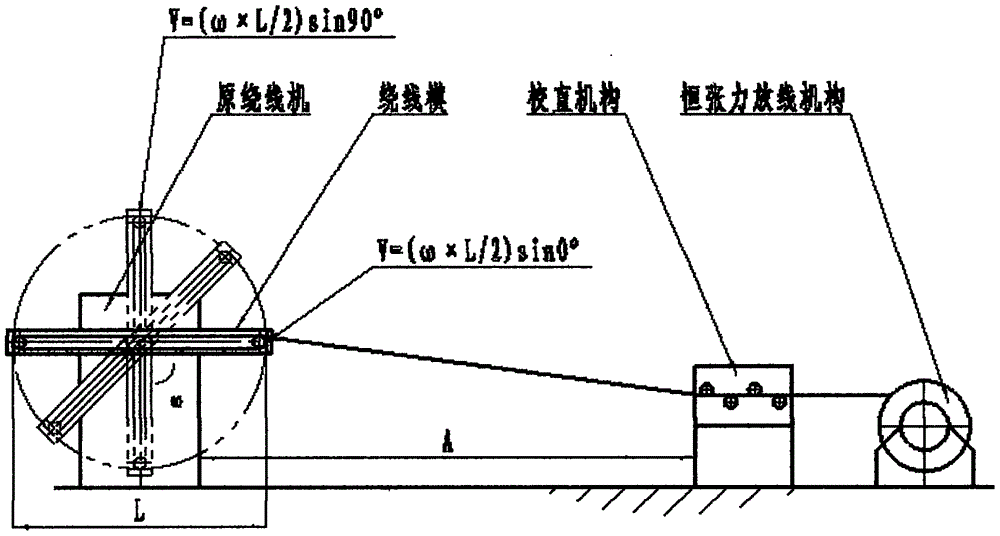

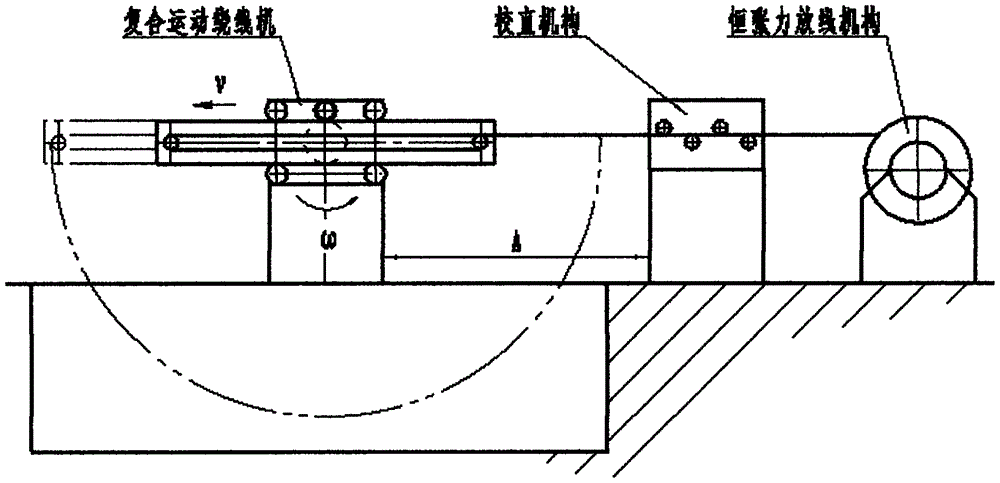

A compound motion and winding machine technology, applied in coil manufacturing, electric components, manufacturing motor generators, etc., can solve problems such as winding speed and tension fluctuations, and achieve the effect of improving winding quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

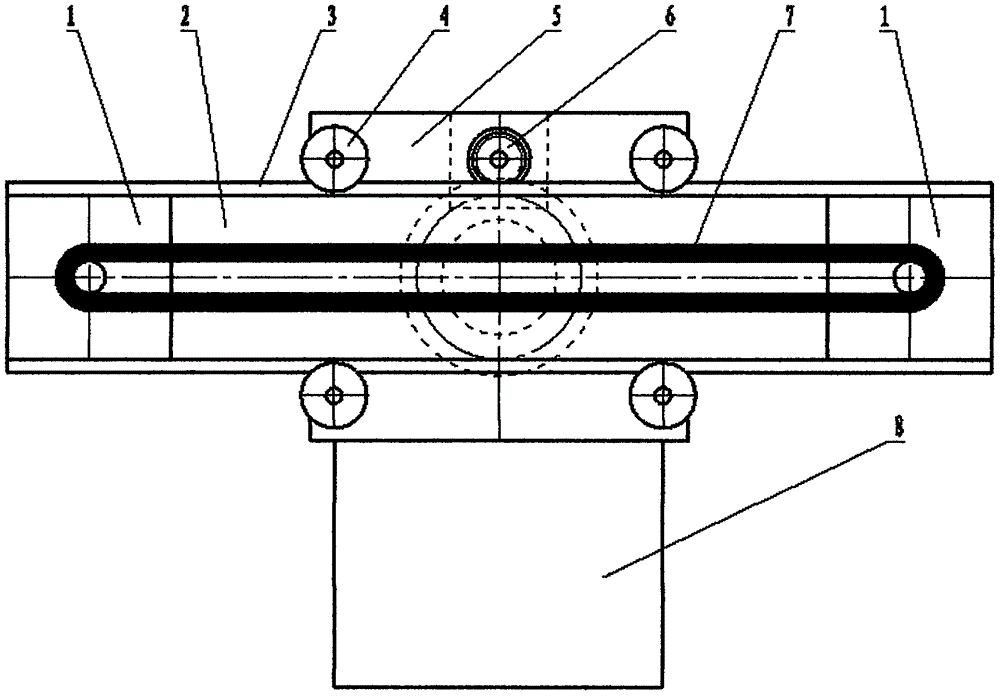

[0011] The specific implementation scheme of this compound motion winding machine (see attached image 3 , 4 ) is to transmit the power of the main control motor and transmission assembly (10) fixed in the main frame (23) to the compound motion winding through the main and driven synchronous pulleys (9, 14) and synchronous belt (11) On the main shaft (17) of the machine, the main shaft (17) is fixed horizontally on the main frame (23) through the front and rear bearings (18, 16) and bearing seats (19, 15), and the front end of the main shaft (17) is fixed by the positioning method The blue plate (21) is fixedly connected with the rectangular plate base (5), and the upper and lower sides of the long frame (2) are respectively fixed with linear guide rails (3), and the guide rail roller assembly (4) guiding the linear guide rail (3) is It is fixed on the right side of the rectangular plate base (5), and the long frame (2) is supported on the right side of the rectangular plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com