Copper strip machining process

A processing technology, copper strip technology, applied in the field of copper strip processing technology, can solve problems such as time-consuming, not easy to operate, large gap between copper strips, etc., to increase the copper strip winding speed and increase the copper strip winding volume , the effect of saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

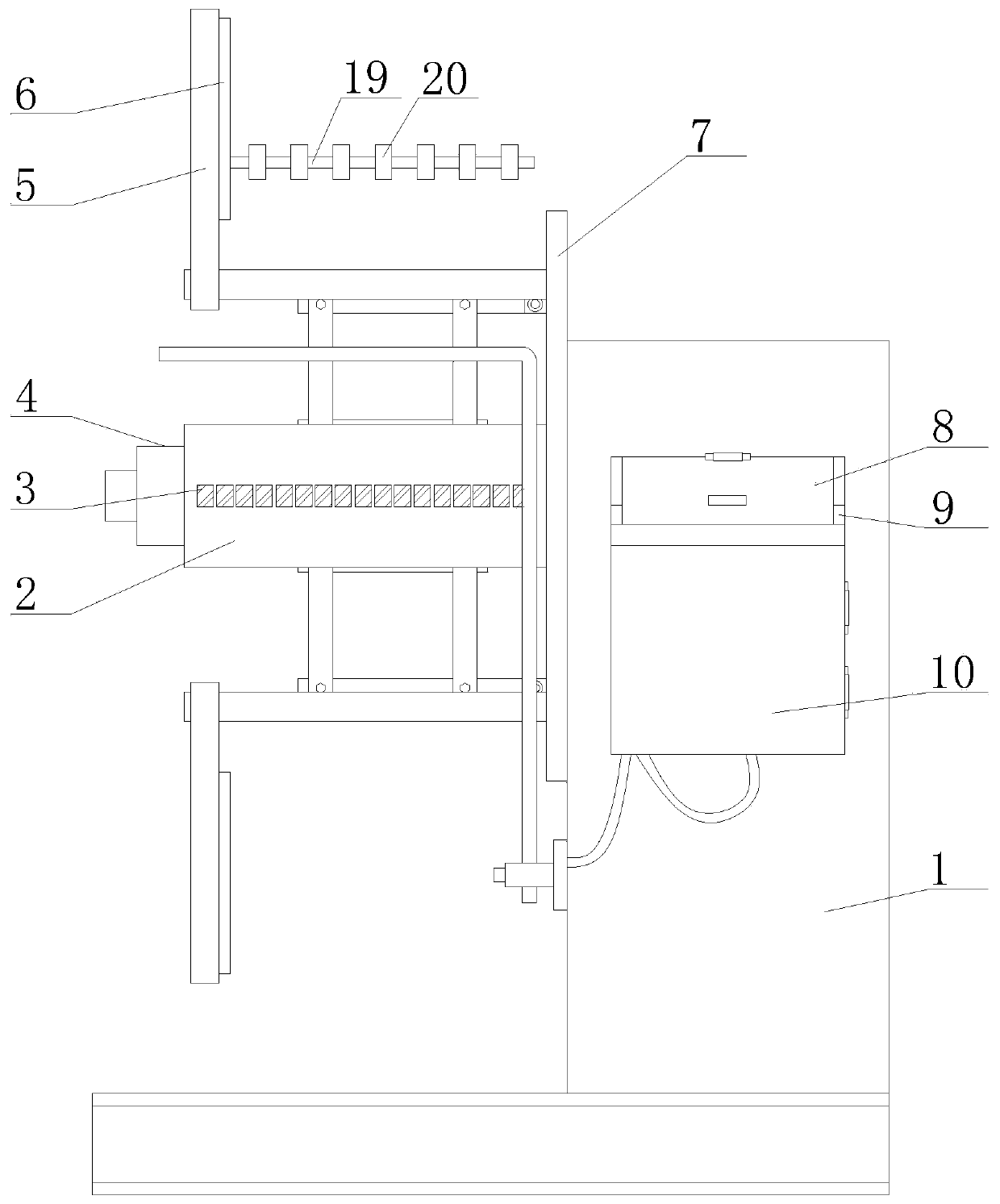

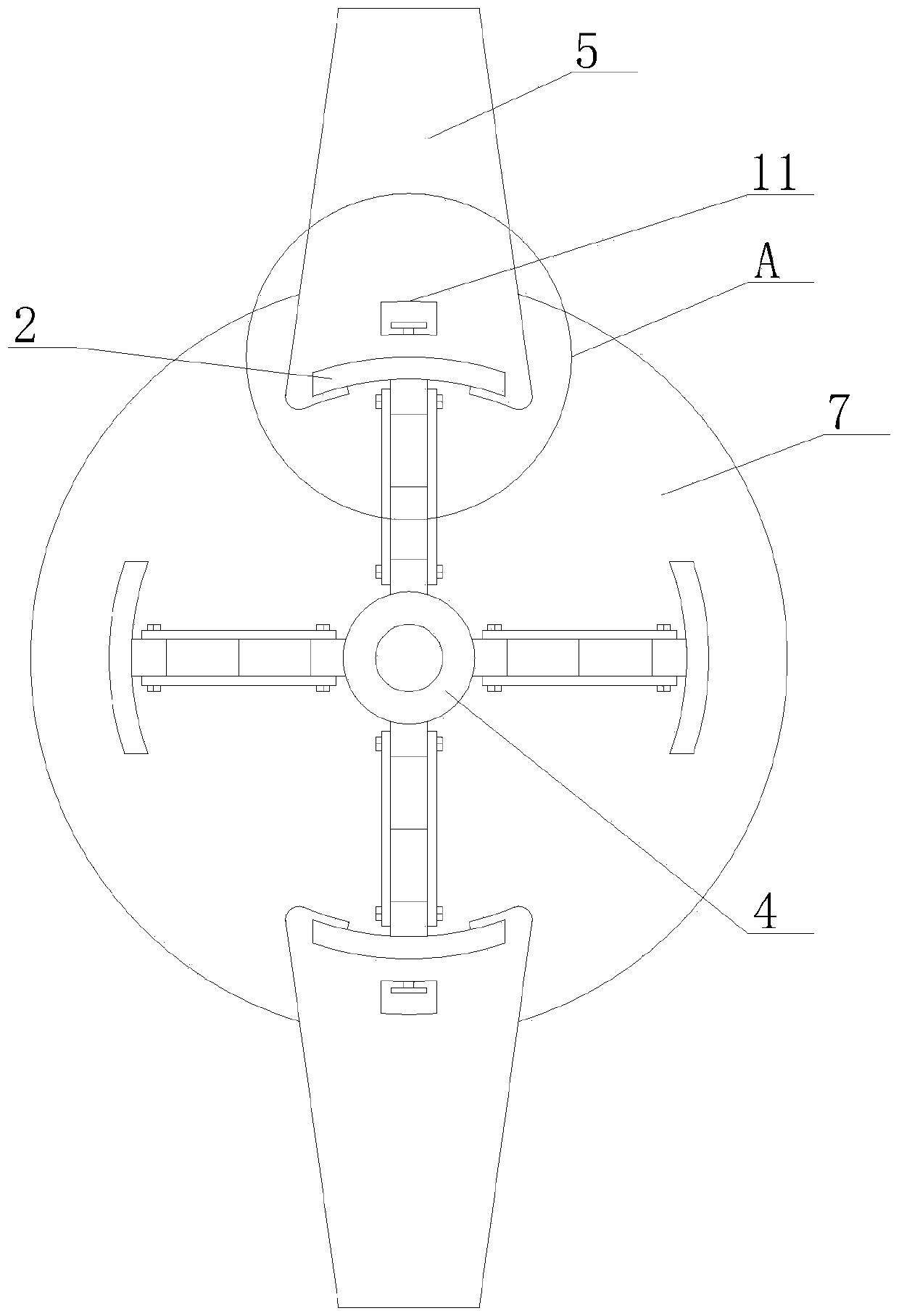

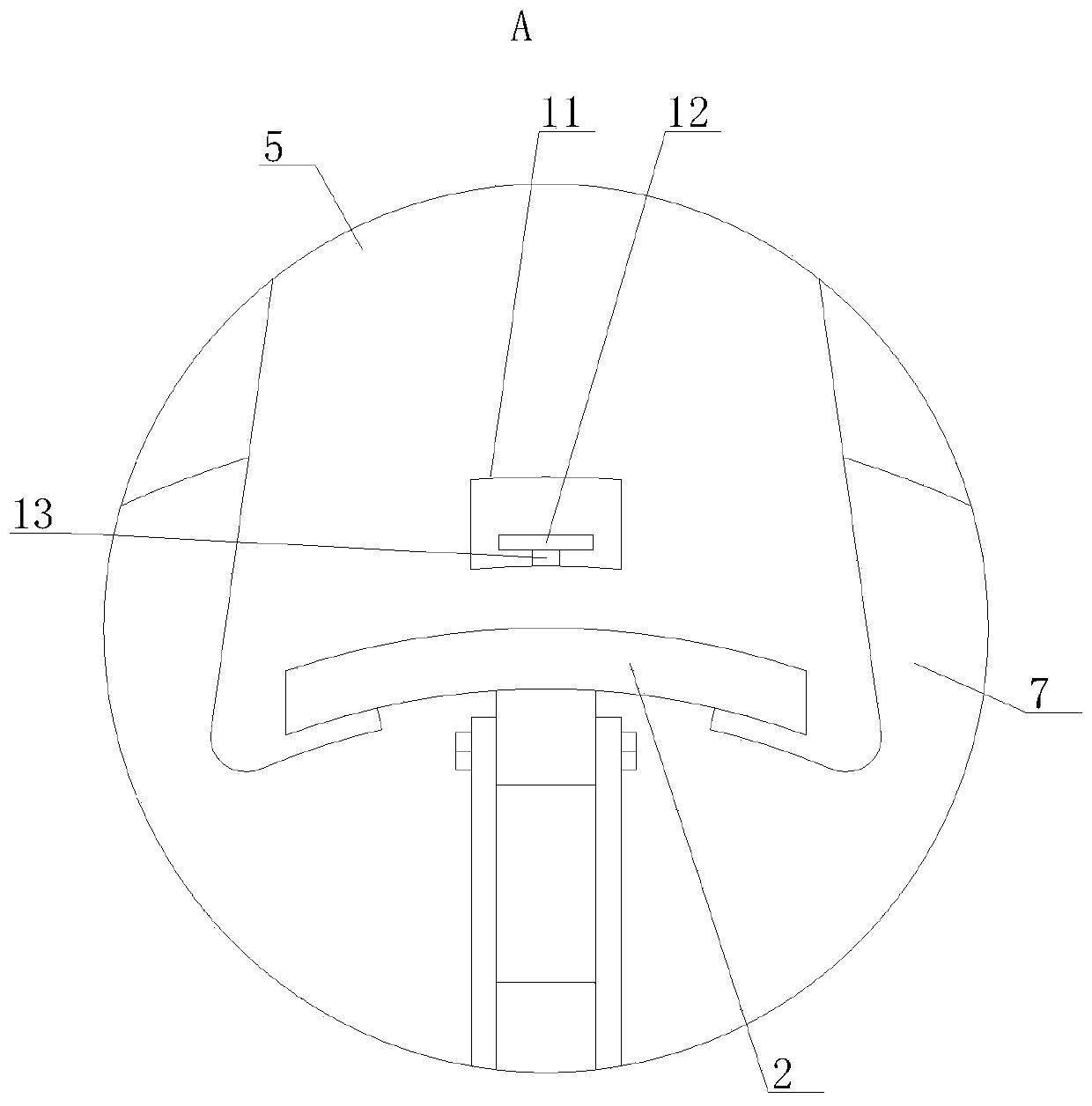

Method used

Image

Examples

Embodiment approach

[0038] As an embodiment of the present invention, the front surface of the body 1 is provided with an operation box 10, and the top surface of the operation box 10 is provided with an operation panel, the top of the operation box 10 is connected with a transparent cover 8, and the transparent cover 8 It is a transparent material member; when working, the operation panel on the top of the operation box 10 can be blocked by the transparent cover 8, thereby avoiding the external dust directly falling on the surface of the operation panel, causing the problem of difficult follow-up cleaning. Play a certain protective role to avoid the problem of contact between external objects and the buttons on the operation panel, and because the transparent cover 8 is a transparent material component, the operator can pass through the transparent cover 8 to the buttons on the operation panel during daily use. The presentation status is observed.

[0039] As an embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com