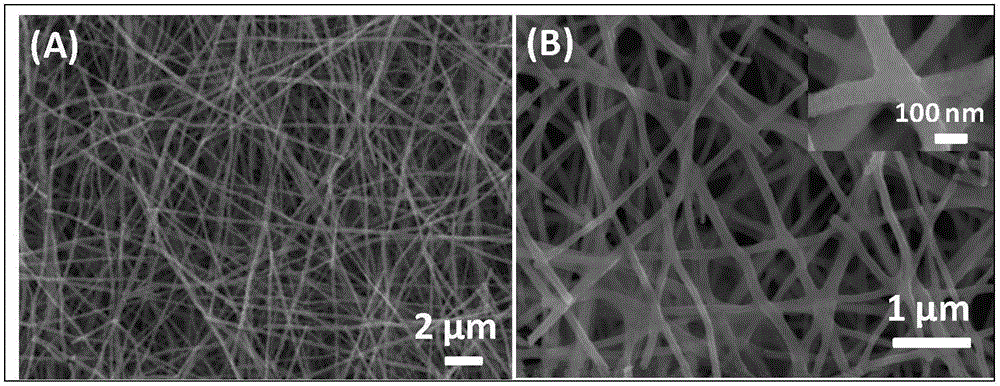

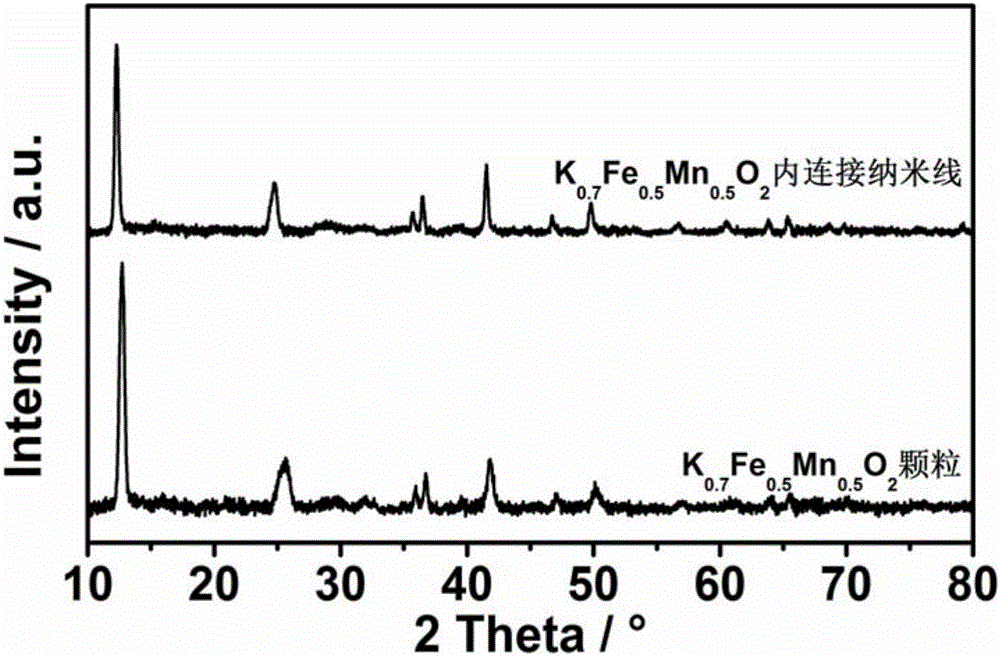

Carbon-coated potassium iron manganate inner connecting nanowire material and preparation method and application thereof

A technology of nanowires and interconnections, applied in the fields of nanomaterials and electrochemistry, to achieve the effects of high reversible specific capacity, uniform morphology and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Carbon coated K 0.7 Fe 0.5 mn 0.5 o 2 A method for preparing an interconnected nanowire material, comprising the steps of:

[0037] 1) 3.5mmol CH 3 COOK, 2.5mmol Fe(NO 3 ) 3 9H 2 O and 2.5mmol Mn(CH 3 COO) 2 Add it to 40.0mL deionized water, and stir it magnetically at 25°C to dissolve it completely, forming a uniform and transparent solution;

[0038] 2) Weigh 4.0 g of polyvinylpyrrolidone (K=30) and add it to the solution obtained in step 1), and stir magnetically for 8 hours to dissolve it completely;

[0039] 3) leave the solution obtained in step 2) for 4 hours to obtain a uniform, transparent, stable precursor solution with a certain viscosity;

[0040] 4) the solution obtained in step 3) was mixed with 0.4ml h -1 The speed is transferred to the syringe, electrospinning is carried out under the condition of positive high voltage 21.0kV, and the nanofiber is received by aluminum foil;

[0041] 5) Put the product obtained in step 4) in a muffle furnace, ...

Embodiment 2

[0050] 1) Add 2.0mmol CH 3 COOK, 1.5mmol K 2 CO 3 , 2.5mm Fe(NO 3 ) 3 9H 2 O and 2.5mmol Mn(CH 3 COO) 2 Add it to 50.0mL deionized water, and stir it magnetically at 25°C to dissolve it completely, forming a uniform and transparent solution;

[0051] 2) Weigh 4.0 g of polyvinylpyrrolidone (K=30) and add it to the solution obtained in step 1), and stir magnetically for 8 hours to dissolve it completely;

[0052] 3) leave the solution obtained in step 2) for 6 hours to obtain a uniform, transparent, stable precursor solution with a certain viscosity;

[0053] 4) the solution obtained in step 3) was mixed with 0.3ml h -1 The speed is transferred to the syringe, electrospinning is carried out under the condition of positive high voltage 21.0kV, and the nanofiber is received by aluminum foil;

[0054] 5) Put the product obtained in step 4) in a muffle furnace, slowly raise the temperature to 320°C at a rate of 2°C / min in an air atmosphere, and keep it warm for 2h;

[0055...

Embodiment 3

[0058] 1) Add 3.5mmol K 2 CO 3 , 2.5mm Fe(NO 3 ) 3 9H 2 O and 2.5mmol Mn(CH 3 COO) 2 Add it to 50.0mL deionized water, and stir it magnetically at 25°C to dissolve it completely, forming a uniform and transparent solution;

[0059] 2) Weigh 4.0 g of polyvinylpyrrolidone (K=30) and add it to the solution obtained in step 1), and stir magnetically for 8 hours to dissolve it completely;

[0060] 3) leave the solution obtained in step 2) for 4 hours to obtain a uniform, transparent, stable precursor solution with a certain viscosity;

[0061] 4) the solution obtained in step 3) was mixed with 0.4ml h -1 The speed is transferred to the syringe, electrospinning is carried out under the condition of positive high voltage 20.5kV, and the nanofiber is received by aluminum foil;

[0062] 5) Put the product obtained in step 4) in a muffle furnace, slowly raise the temperature to 280°C at a rate of 1°C / min in an air atmosphere, and keep it warm for 2h;

[0063] 6) The product obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com