Preparation method and device of indium arsenide thin film material

A thin film material, a technology of indium arsenide, which is applied in the field of preparation of indium arsenide thin film materials, can solve the problems of lattice mismatch, complicated operation and complicated operation, and achieves the effect of dense film surface, obvious preferred orientation and uniform surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

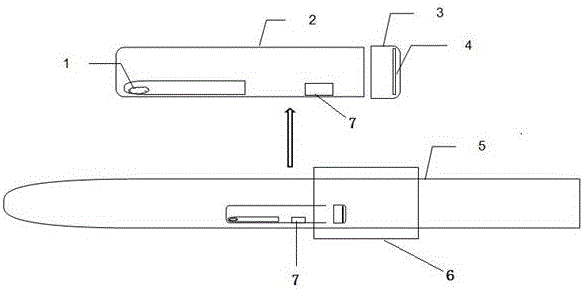

[0032] The object of the present invention is to provide a kind of preparation method of indium arsenide thin film material (such as figure 1 shown), specifically include the following steps:

[0033] (1) Cleaning of the single crystal Si(111) substrate: firstly clean the substrate with acetone for 3 min under the action of ultrasonic waves to remove oil stains and dust on the surface to prevent cracks and defects in the prepared film; then use absolute ethanol on the Wash for 3 minutes under the action of ultrasonic waves to remove residual acetone and some impurities on the surface; then use NH 4 OH, H 2 o 2 、H 2 The mixed solution of O was corroded for 3 minutes, where V NH4OH :V H2O2 :V H2O =1:2:5, then use HCl, H 2 o 2 、H 2 The mixed solution of O was corroded for 3 minutes, where V HCl :V H2O2 :VH2O =1:2:5; After taking it out, wash it alternately with a large amount of cold and hot deionized water, and then use HF, H 2 The mixed solution of O was corroded f...

Embodiment 2

[0040] The object of the present invention is to provide a method for preparing an indium arsenide thin film material, which specifically includes the following steps:

[0041] (1) Cleaning of the single crystal Si(111) substrate: first, clean with acetone for 4 minutes under the action of ultrasonic waves to remove surface oil stains and dust, so as to prevent cracks and defects in the prepared film; Wash for 4 minutes under action to remove residual acetone and some impurities on the surface; then use NH 4 OH, H 2 o 2 、H 2 The mixed solution of O was corroded for 4min, where V NH4OH :V H2O2 :V H2O =1:2:6, then use HCl, H 2 o 2 、H 2 The mixed solution of O was corroded for 4min, where V HCl :V H2O2 :V H2O =1:2:6; After taking it out, wash it alternately with a large amount of cold and hot deionized water, and then use HF, H 2 The mixed solution of O was corroded for 4min, where, V HF :V H2O =1:3; After taking it out, wash it alternately with a large amount of co...

Embodiment 3

[0048] The object of the present invention is to provide a method for preparing an indium arsenide thin film material, which specifically includes the following steps:

[0049] (1) Cleaning of the single crystal Si(111) substrate: first, wash with acetone under the action of ultrasonic waves for 5 min to remove oil stains and dust on the surface to prevent cracks and defects in the prepared film; then use absolute ethanol on the Wash for 5 minutes under the action of ultrasonic waves to remove residual acetone and some impurities on the surface; then use NH 4 OH, H 2 o 2 、H 2 The mixed solution of O was corroded for 5min, where V NH4OH :V H2O2 :V H2O =1:2:7, then use HCl, H 2 o 2 、H 2 The mixed solution of O was corroded for 5min, where V HCl :V H2O2 :V H2O =1:2:7; After taking it out, wash it alternately with a large amount of cold and hot deionized water, and then use HF, H 2 The mixed solution of O was corroded for 5 min, where, V HF :V H2O =1:5; After taking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com