Long-term interval prediction method for iron and steel industry blast furnace gas on the basis of information granularity optimum allocation

A technology of blast furnace gas and iron and steel industry, applied in the field of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

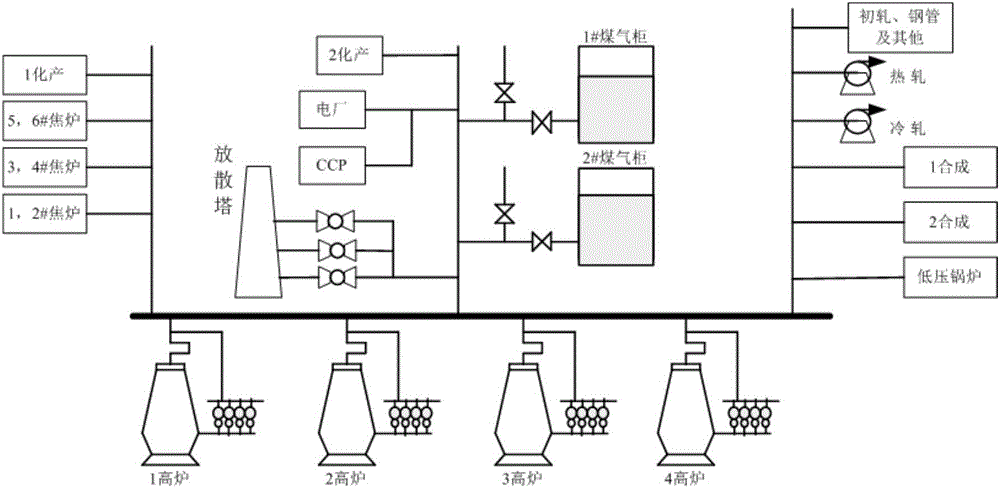

[0026] In order to better understand the technical solution and specific implementation of the present invention, the blast furnace gas system of Baoshan Iron and Steel Works, which has a relatively high level of informatization in the domestic iron and steel industry, will be further described below as an example. Depend on figure 1 It can be seen from the schematic diagram of Baosteel’s blast furnace gas pipeline network that the system contains four converters as generating units, hot blast stoves, etc. constitute consumption units, low-pressure boilers, power plants, etc. are adjustable units of the pipeline network, and two gas cabinets It is connected to store excess gas at the end of the pipeline network, which acts as a buffer for the balance of the pipeline network. In addition, there are gas mixing stations, gas pressurization stations, etc. as transmission and distribution systems. Because the actual configuration of the pipeline network is complex, the laying lines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com