Lithium battery batch code scanning system and method based on image processing

An image processing, lithium battery technology, applied in electromagnetic radiation induction, instruments, induction record carriers, etc., can solve the problems of increasing equipment cost, equipment space and maintenance difficulty, affecting the sorting efficiency of lithium batteries, and inconsistent battery directions, etc. The effect of shortening sorting time, saving equipment cost and space, strong adaptability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

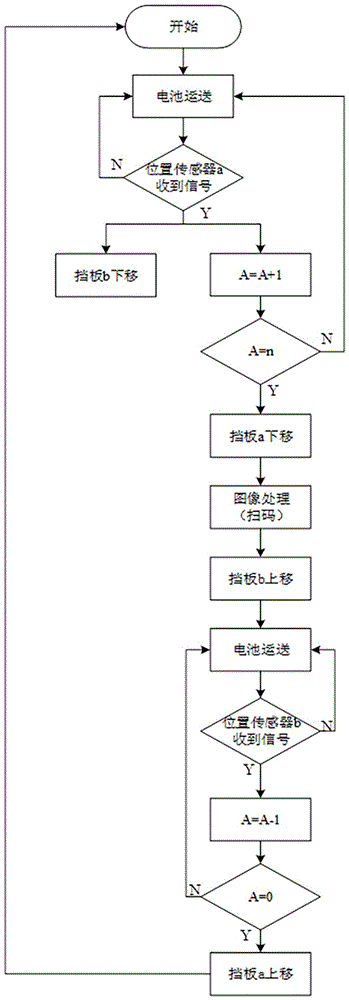

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

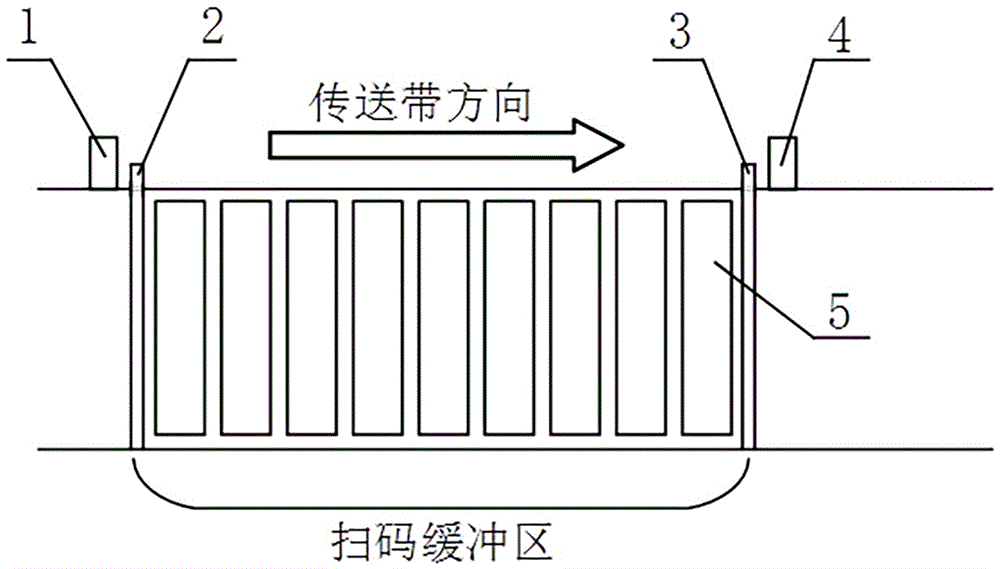

[0024] Such as figure 2 As shown, the lithium battery batch code scanning system based on image processing of the present invention includes: an industrial computer, an image acquisition unit, and a motion control unit; the image acquisition unit includes an image acquisition card and a high-speed camera; the motion control unit includes a manipulator, Conveyor belt, cylinder, baffle, position sensor; the baffle includes baffle a2, baffle b3, both baffles are controlled by the cylinder; between the baffle a2 and baffle b3 is the code scanning buffer zone, The high-speed camera is installed above the code scanning buffer; the position sensor includes a position sensor a1 and a position sensor b4, the position sensor a1 is placed on the front side of the baffle a2, and the position sensor b4 is placed on the rear side of the baffle b3; The distance between the baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com