A method for measuring radiation dose distribution and unevenness of products

A technology of irradiation dose and measurement method, applied in the field of product irradiation quality control in irradiation processing, can solve the problems of cumbersome, heavy workload, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1, the determination of the unevenness of irradiation dose of dehydrated vegetables and jujube.

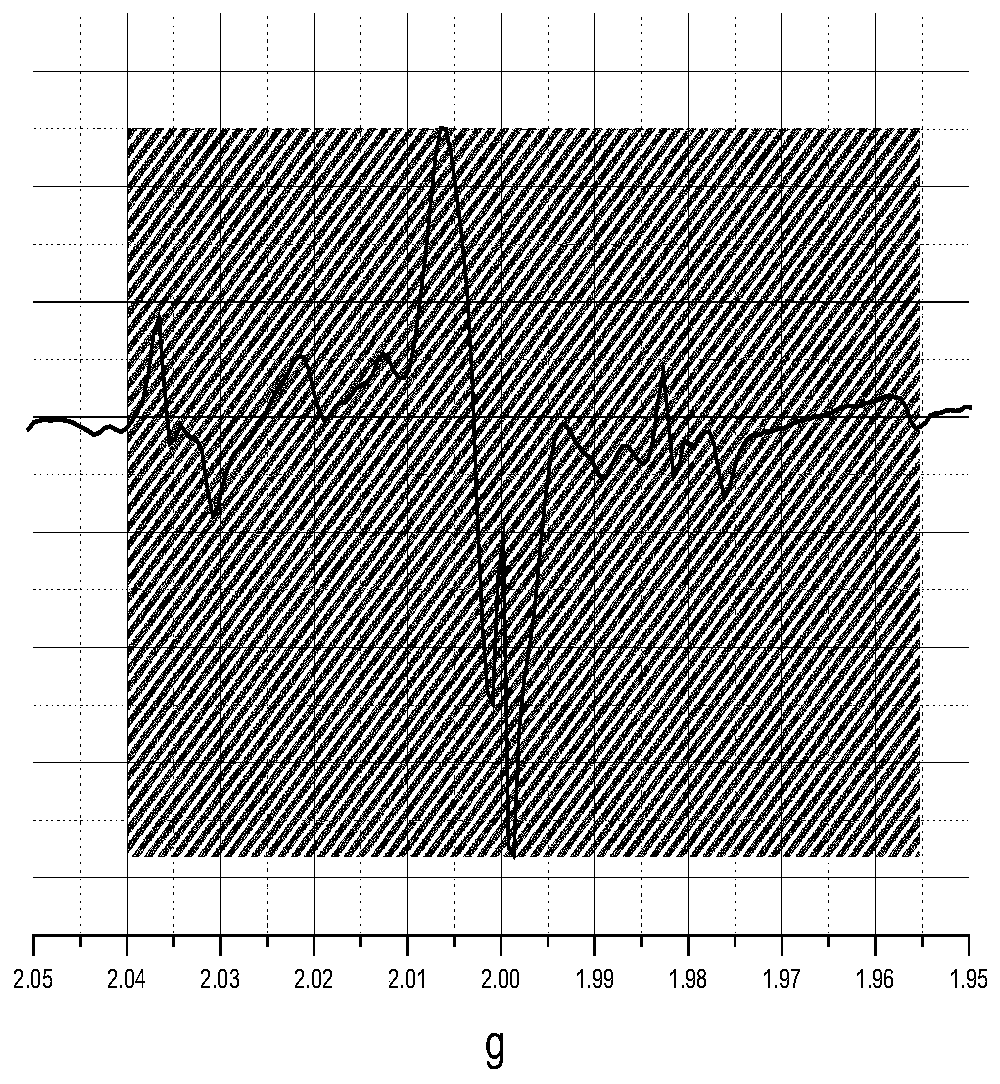

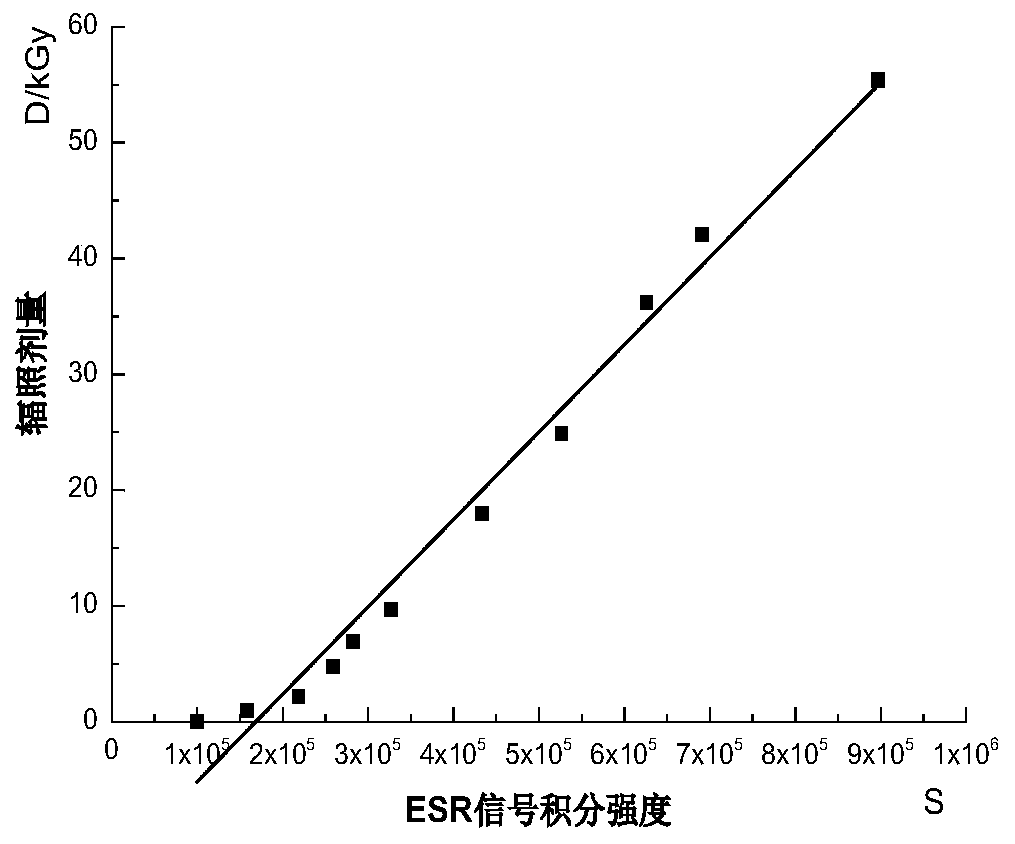

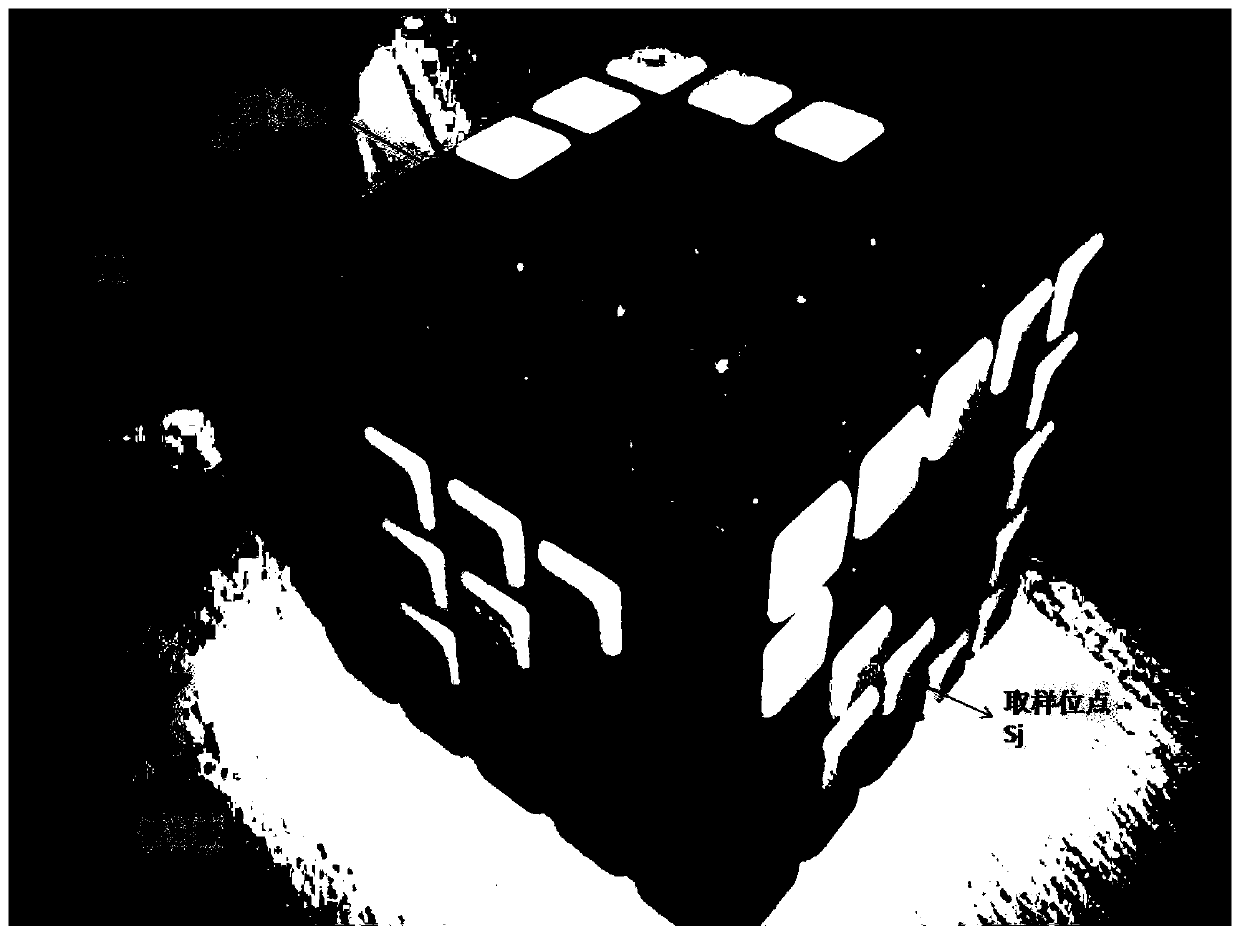

[0052] Dehydrated vegetables and jujube packing cartons are 30×25×20cm 3 , 25×25×20cm 3 ,Co 60 γ-irradiation, using dynamic suspension, spreader 55×85×160cm 3 , the predetermined irradiation dose is 6kGy, 2kGy. Select 2 positions in the spreader filled with dehydrated vegetables and red dates: the top position min (minimum dose position), the front 3 / 4 position max (maximum dose position), and mark on the outer surface of the carton ( before or after irradiation), samples were taken within 2 days after irradiation. Tear open the above carton, cut out 2.5×4cm from the interlayer of the inner wall of the carton at the mark 2 Paper, weighing 0.135g, curled into a cylinder, kneaded, stuffed into the ESR test tube along the tube wall, and pushed into the bottom of the tube with a special stainless steel shovel, compacted, so that the sample height is between 2.5-...

Embodiment 2

[0058] Embodiment 2, electron beam irradiated dressing and mask dose unevenness measurement.

[0059] Dressing and mask packaging carton specifications are 60×28×35cm 3 、30×25×27cm 3 , electron beam irradiation (10MeV), under the beam transport adopts the plate chain transmission method, the predetermined irradiation dose is 10, 15kGy. Select 2 points on the flat surface and the edge of the dressing and mask packaging carton respectively: the edge min (minimum dose), the center max (maximum dose), and mark on the outer surface of the carton (irradiation before and after), samples were taken within 7 days after the irradiation was completed. Tear open the above carton, cut out 2.5×4cm from the interlayer of the inner wall of the carton at the mark 2 Paper material, weighing 0.150g, curled into a cylinder, kneaded, stuffed into the ESR test tube along the tube wall, and pushed into the bottom of the tube with a special stainless steel shovel, compacted, so that the sample hei...

Embodiment 3

[0064] Embodiment 3, measurement of X-ray irradiation blood collection needle and glove dose unevenness.

[0065] The specifications of cartons for blood collection needles and gloves are 65×38×35cm respectively 3 、40×35×67cm 3 , X-irradiation (5MeV), under-beam transportation adopts crawler transmission, and the predetermined irradiation dose is 25, 35kGy. Select 2 points respectively on the flat surface and the edge of the lancet and glove packaging carton: edge min (minimum dose), center max (maximum dose), and mark on the outer surface of the carton (radiation Both before and after irradiation), samples were taken within 15 days after the irradiation was completed. Tear open the above carton, cut out 2.5×4cm from the interlayer of the inner wall of the carton at the mark 2 Paper material, weighing 0.150g, curled into a cylinder, kneaded, stuffed into the ESR test tube along the tube wall, and pushed into the bottom of the tube with a special stainless steel shovel, comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com