Conveyor belt synchronous tracking method, device and system for robot

A technology of synchronous tracking and robotics, which is applied in the direction of conveyor control devices, conveyors, manipulators, etc., and can solve problems such as the increase in the movement distance of the error target object, the error, and the speed fluctuation of the conveyor belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

[0048] As used herein, the term "comprising" and its variations may be understood as open-ended terms meaning "including but not limited to". The term "based on" may be understood as "based at least in part on". The term "one embodiment" can be read as "at least one embodiment". The term "another embodiment" may be understood as "at least one other embodiment".

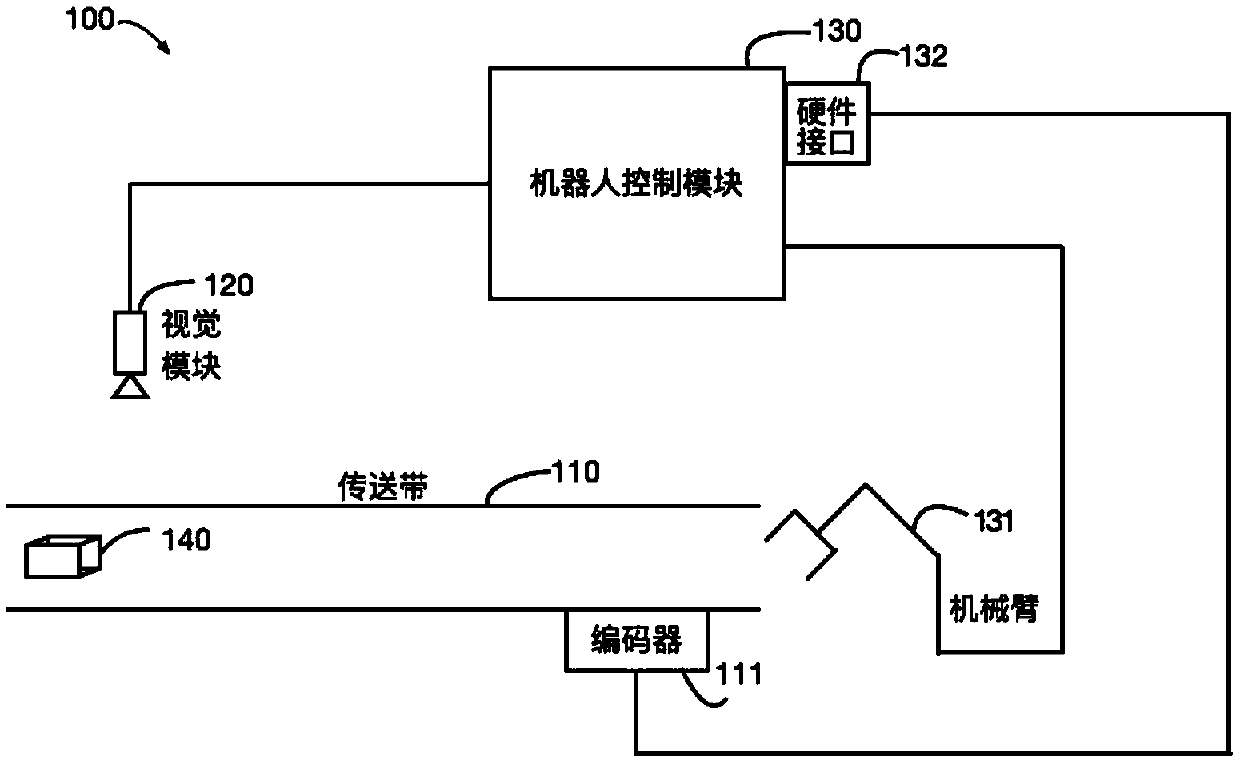

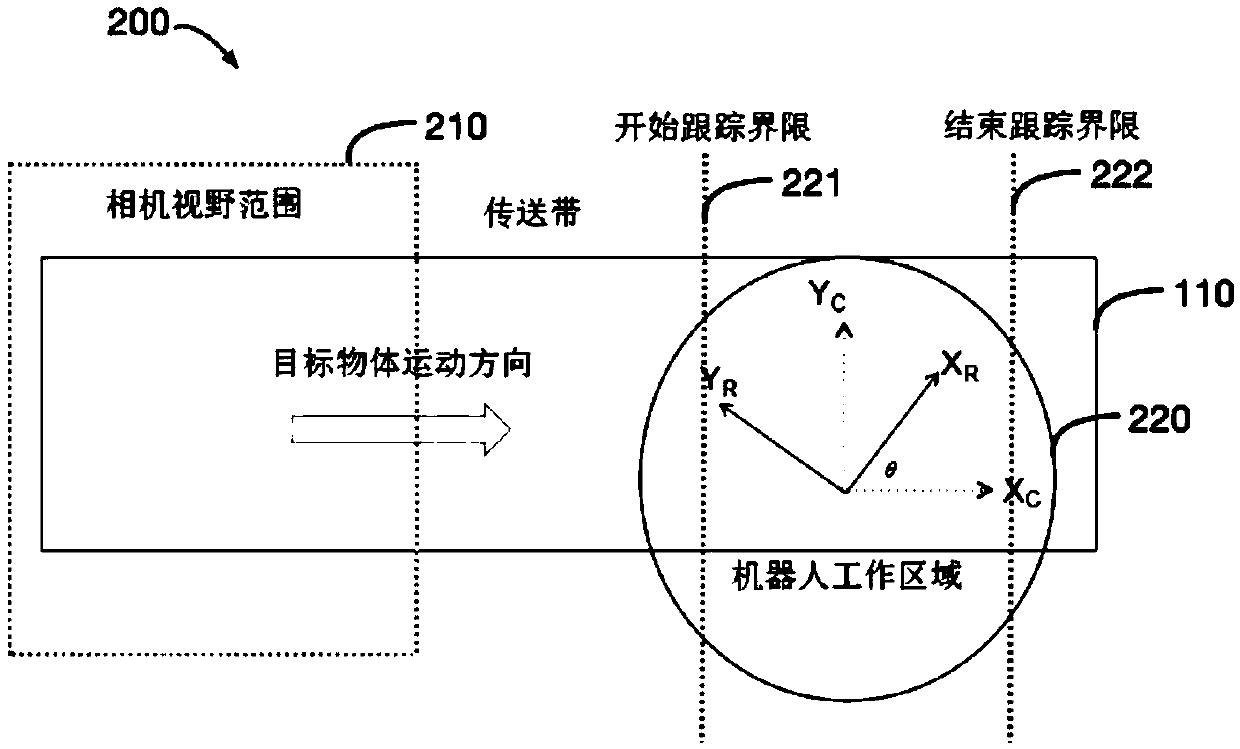

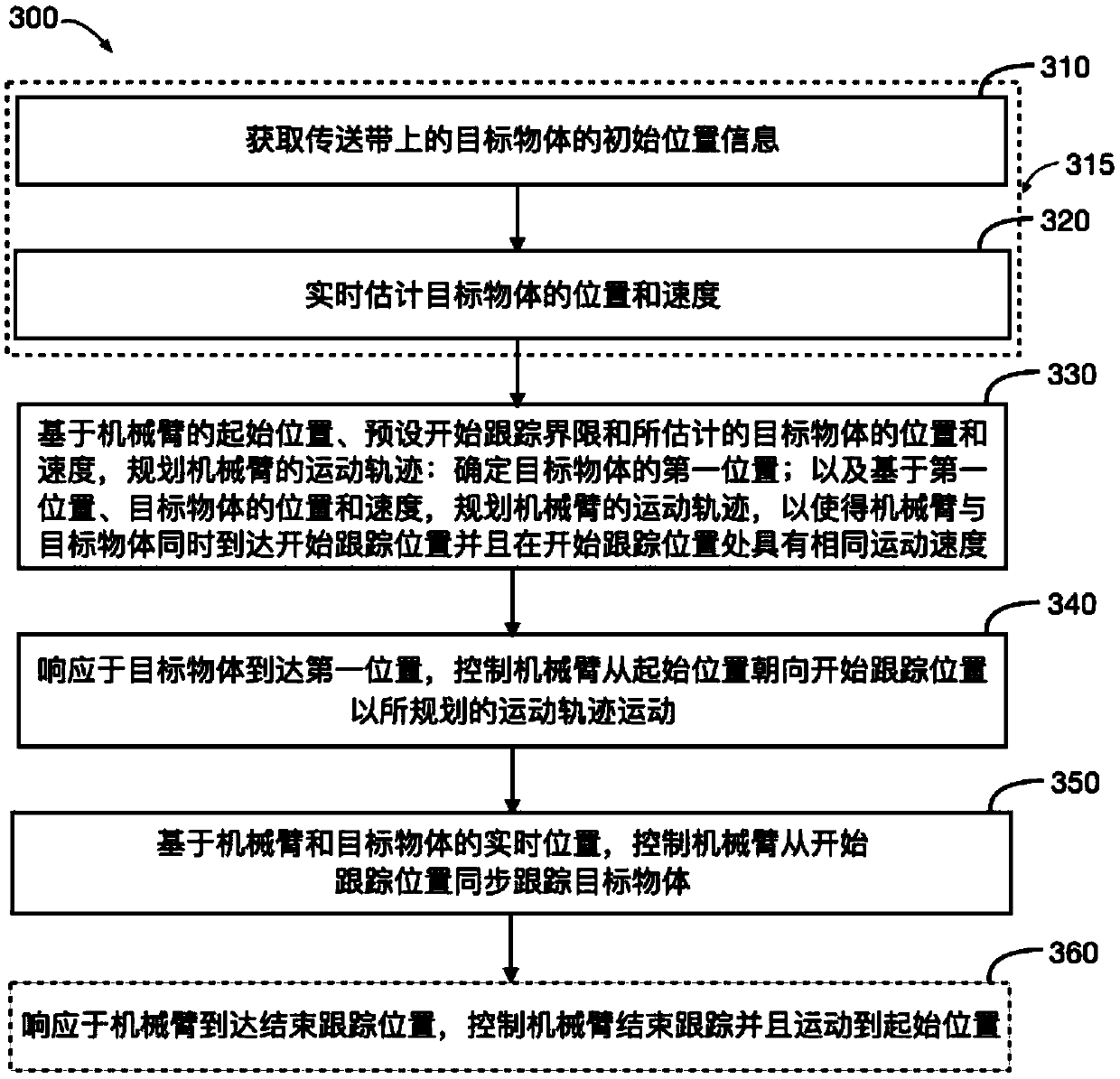

[0049] As mentioned above, the existing operations such as grasping the target object on the conveyor belt have the defect that the operation purpose cannot be accurately and quickly realized. The embodiment of the present invention pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com